Site pages

Current course

Participants

General

Module- 1 Scope and importance of food processing....

Module- 2 Processing of farm crops; cereals, pulse...

Module- 3 Processing of animal products

Module- 4 Principal of size reduction, grain shape...

Module- 5 Theory of mixing, types of mixtures for ...

Module- 6 Theory of separation, size and un sized ...

Module- 7 Theory of filtration, study of different...

Module- 8 Scope & importance of material handl...

19 April - 25 April

26 April - 2 May

Lesson 22. Capacity and effectiveness

Efficiency of separation, along with capacity, is the measure of performance in industrial screening. Capacity and effectiveness are opposing factors as maximum effectiveness is related to small capacity, while large capacity is only attainable at the expense of efficiency. A reasonable balance between capacity and effectiveness is desired in practice. Although accurate relationships are not available for estimating operating characteristics in screen operations, certain fundamentals apply and may be used as guidelines when running and designing a screening process.

The capacity of a screen is measured by the mass of material which can be fed per unit time to a unit area of screen, and can be simply controlled by varying the feed rate to the equipment. The effectiveness obtained for a given capacity is dependent upon the specific nature of the screening operation. The chance of passing through the screen of an undersize particle is a function of the number of times the particle strikes the screen surface, as well as its probability of passage in a single contact. If a screen is overloaded, the number of contacts is small and the chance of passing on contact is reduced by particle interference. The effectiveness is improved by reducing the capacity as then there will be more contacts per particle and better chances for passing through the screen aperture on each contact.

A particle would have an ideal opportunity of passage when striking the surface perpendicularly, which would only be possible if it were oriented with its minimum dimensions parallel to the screen surface. Additional conditions would be no interference by other particles, as well as not sticking to, or wedging into, the screen surface. None of these conditions apply to actual screening, but this ideal situation can be used as a basis for estimating the effect of mesh size and wire dimensions on screen performance. If the width of a screen were negligible in comparison to the size of the openings, the wires would not interfere with particle passage and, practically, the entire screen surface would be active. In such a case, the probability of passage of a striking particle would approach unity. In actual screening, the diameter of the wire, or the fraction of the surface not constituting openings, is significant and the solid meshes strongly affect screen performance, especially by retarding the passage of particles nearly as large as the screen openings.

Calculation of Capacity and Effectiveness of screens

The efficiency of a screening operation may be evaluated by simple mass balances over screen. Consider that the feed to a screen consists of materials A and B, where A is the oversize and B is the undersize material. Out of the total materials fed to the screen, some part of it is removed as overflow and remaining part is collected as underflow.

Let F be the mass flow rate of feed, (kg/h)

O be the mass flow rate of overflow, (kg/h) and

U be the mass flow rate of underflow, (kg/h) ; also, let

XF be the mass fraction of material A in the feed,

XO the mass fraction of material A in the overflow and

XU the mass fraction of material A in the underflow.

Furthermore, the fractions of material B in the feed, overflow and underflow are 1 − XF, 1−XO and 1 −XU, respectively.

Since the total of the material fed to the screen must leave either as overflow or underflow thus overall material balance over a screen is;

F = O + U (1)

Material balance of ‘A’ over a screen is

XF.F = XO.O + XU.U (2)

From equation (1), we have

F- O = U (3)

Similarly substituting the value of U from equation (3) into equation (2), we get

F.XF = XO .O + XU. (F – O) (4)

F.XF = XO .O + XU.F – XU.O

(XF – XU) F = (XO – XU) O

Similarly eliminating O from equation (1) and equation (2), gives

Effectiveness of screens and its calculation

The effectiveness of a screen (screen efficiency) is a measure of success of the screen in closely separating undersize and oversize materials. In case of a perfectly functioned screen, all the oversize materials would be in overflow and all the undersize material would be in underflow.

The screen effectiveness based on oversize material is the ration of the amount of oversize material that is actually present in the overflow to the amount of oversize material entering with the feed.

Similarly, screen effectiveness based on undersize material:

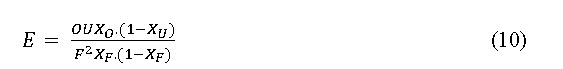

The overall combined effectiveness (E) is given by

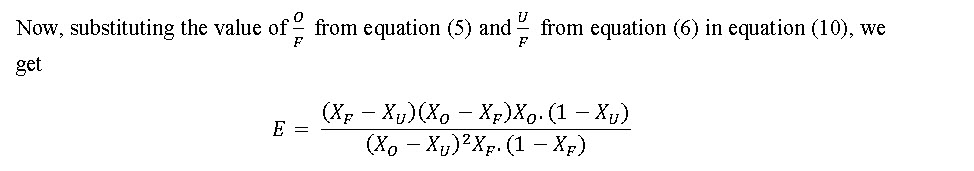

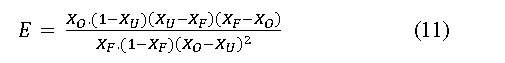

Substituting EO and EU in equation (3.9), we get

Equation (11) is an alternative expression to evaluate screen effectiveness without involving the streams and using only the fractions.

Factors affecting efficiency

The probability of passage of a particle through a given screen mainly depends on

(i) the fraction of the total surface represented by openings

(ii) the ratio of the diameter of the particle to the width of an opening in the screen, and

(iii) the number of contacts between the particle and the screen surface

If all these factors were constant, the average number of particles passing through a single screen opening in a unit time would be constant and independent of the size of the screen opening. The capacity of a screen in mass per unit time divided by the mesh size would therefore be constant for any specified conditions of operation. However, in practice, When large and small particles are present, the large ones tend to segregate in a layer next to the screen, preventing the smaller particles from reaching the screen surface thus reducing capacity and lower efficiency.

Pertaining to moisture, either dry particles or particles moving in a stream pass more easily through a screen opening than damp particles, which are prone to stick to the screen surface and to each other. In terms of size aspects, as particle size is reduced, screening becomes progressively more difficult, while capacity and efficiency tend to decrease. Blinding or clogging of the openings is particularly likely to occur when particles have sizes very close in dimension to the screen aperture. In general terms, there are three possibilities of a given particle facing a screen aperture:

(a) the particle being too large in relation to the aperture so it would be easily retained;

(b) the particle being too small in relation to the aperture so it would go through easily; and

(c) the particle having a critical dimension so it would be trapped and promote blinding or clogging of the screen surface.

Surface roughness of the grain and surface cohesive and adhesive property affects the selection and efficiency of the screen.

References

Sahay, K. M. and Singh, K. K. (1994). Unit operations of Agricultural Processing. Vikas Publishing House Pvt. Ltd., New Delhi.

Anon. (2004). Course manual for short course on Post harvest processing and agro processing centres for value addition in rural areas. Post Harvest Technology Scheme, University of Agricultural Sciences, Bangalore.