Site pages

Current course

Participants

General

Module- 1 Scope and importance of food processing....

Module- 2 Processing of farm crops; cereals, pulse...

Module- 3 Processing of animal products

Module- 4 Principal of size reduction, grain shape...

Module- 5 Theory of mixing, types of mixtures for ...

Module- 6 Theory of separation, size and un sized ...

Module- 7 Theory of filtration, study of different...

Module- 8 Scope & importance of material handl...

19 April - 25 April

26 April - 2 May

Lesson 29. Scope and Importance of Material Handling

Material handling includes a number of operations that can be executed either by hand (manual) or by mechanical means or devices to convey material and to reduce the human drudgery.

After harvesting, the grains are moved, transported or conveyed from place to place. In earlier periods all these operations were manual. The grains were threshed and bagged by human labour. Mechanical handling delivers aim to lighten the work of human labour. Grains were transported several times through storage and milling plants, and the milled food products were conveyed manually to customers. Thus, grains were handled too much involving increased cost and human drudgery. Now a day, some mechanical devices have replaced human labour, other supplement it or in some case make possible to handle larger quantities of grains per unit human labour. The most common types of mechanical devices for grain handling are;

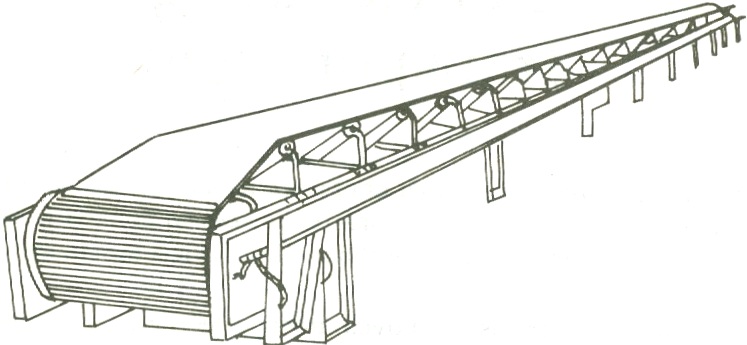

1 Belt conveyor

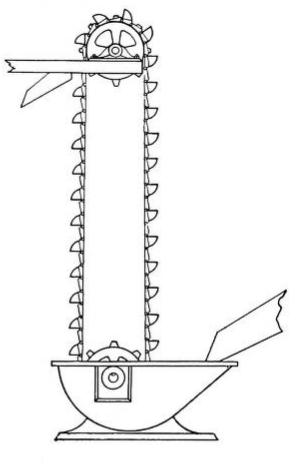

2 Bucket elevator

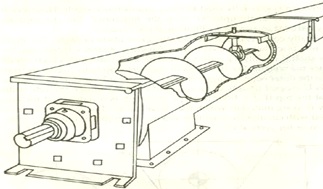

3 Screw Conveyor

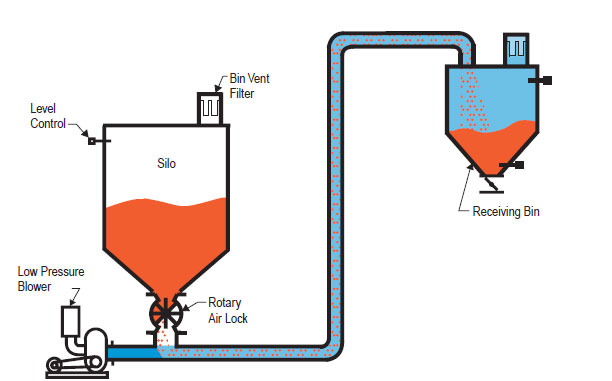

4 Pneumatic conveyor

The selection of proper conveying system is important for ease in operation and getting desired capacity for a particular product. The following principles should be taken into account before selecting conveying systems.

-

The conveying device has to be selected according to the characteristics of the materials being conveyed.

-

In a conveying system possibility of use of gravity should be taken into consideration.

-

The stability of the conveyor must be ensured under all normal working and climatic conditions.

-

The dead load of the conveyor should be low in relation to the weight of transported product.

-

The capacity of handling/conveying equipment should match with the capacity of processing unit of units.

-

Spillage of conveyed products should be avoided.

-

Pollution of the environment due to noise or dust by the conveying system should also be avoided.