Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Lesson.13 Hot Air Assisted Drying

Inroduction

Hot Air Drying

Hot air drying is one of the most common methods of drying in which air is circulated by natural or forced convection though or over the bed of product. The product may be spread on the screened trays or in a controlled room or platform. The drying medium is air which is heated generally in the temperature range from ambient to 110°C during root drying depending upon the nature of foods. The most common methods of hot air drying include tray drying/cabinet drying and fluidized bed drying. There are several sizes of trays depending on type of product. The root products are generally spread on perforated trays in a single layer or multiple layers depending upon the required tray loading density in kg product/m2 of the tray area. Air having temperature in the range ambient to 100°C is blown either in cross flow or parallel flow mode in the dryer in the velocity range 0.1 to 1.9 m/s. Foods like carrots, sweet potato, potato and onion are sensitive to temperature, the problem of darkening in colour, loss of flavour and decrease in rehydration ability of the dried product occur during hot air drying that can be solved by some pre-treatments like blanching, chemical dipping and osmotic dehydration. The range of air temperature and velocity used during hot air drying of various foods is given in Table 3. It can be observed the table that hot air drying is most common method of root drying as compared to other methods.

Hot air drying of foods can be carried out in single and multiple stages. Literature shows that multistage drying of root like onion is more effective than the single stage. Munde et al. [18] developed a process for multistage dehydration of onion flakes. They dried 4 mm thick onion slices at 50°, 60°, 70°, 80°, 90° and 100°C temperatures up to 30, 40, 50 and 60 per cent cut-off moisture levels and the remaining moisture was removed at the control temperature 50°C. On the basis of quality factors and production time, they recommended the two stage dehydration process for onions and also stated that the four stage dehydration process saves 24% drying time at the cost of very marginal sacrifice in quality from the possible best two stage dehydration process.

Fluidized Bed Drying

Fluidized bed drying is carried out by passing the air at fluidization velocity through a bed of product so as to fluidize the material. In fluid bed drying, heat is supplied by the fluidization air, but the air flow need not be the only source. Heat may be effectively introduced by heating surfaces (panels or tubes) immersed in the fluidized layer. Uniform processing conditions are achieved by passing a gas (usually air) through a product layer under controlled velocity conditions to create a fluidized state. Some foods like green peas, onions rings, garlic, carrot pieces can be dried using fluidized bed. Generally fluidized bed drier can be used with air temperatures in the range 40° to 80 °C and air velocity equivalent to minimum fluidization to dry the products. In case of fluidized bed drying, after the initial falling rate period, temperature no longer controls the drying rate. The fluidized bed dried products show better colour, rehydration properties, greater retention of chemical compounds and better overall sensory quality than those dried by solar and hot air thin layer drying methods. Due to the high air velocities required to fluidize the material, power requirements for the fan are high and the thermal efficiency is low compared to conventional (fixed bed) drying. But re-cycling of the exhaust air can be done to improve the thermal efficiency.

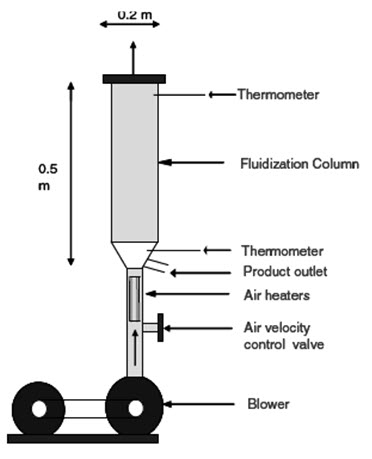

Figure . Schematic Diagram of experimental setup of Fluidized Bed drying

This type of dryer in which individual grains are suspended and sometimes transported by air moving at high velocity, 2-3 m/s, can produce very evenly dried grain. Recent research in the Philippines (Sutherland & Ghaly 1990; Tumambing & Driscoll 1991) has indicated that the fluid bed dryer has promising potential for the rapid first-stage drying of paddy to 18% moisture in two-stage drying (see above). Paddy at a bed depth of 100 mm can be dried from 24% to 18% moisture in 15 minutes with air at 100°C and a velocity of 2 m/s, with no adverse effects on quality. However, due to the high air velocities required to fluidise the paddy, power requirements for the fan are high and the thermal efficiency is low compared to conventional (fixed bed) drying.

Types of Fluidized bed dryers

Well mixed fluidized bed dryers

Vibrated fluidized bed dryers

Plug flow fluidized bed dryers

Heat pump drying (room temperature drying)

-

Low temperature drying method

-

Use of refrigeration system to remove the moisture from the air

-

Humidity of air is reduced at evaporator and heat rejected at condenser is used to heat the dry air

-

Increases the drying rate at low air temperature

-

Results in high quality dehydrated food product

-

Time and energy saving as compared to other methods of drying