Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Lesson.17 Microwave Assisted Drying

The application of microwave energy to dry foods is becoming more popular as it is a good approach for coping with certain drawbacks of conventional drying.

Mechanism of Heating

In microwave heating or drying, microwave-emitted radiation is confined within the cavity and there is hardly heat loss by conduction or convection so that energy is mainly absorbed by a wet material placed in the cavity. Furthermore, this energy is principally absorbed by water in the material, causing temperature to raise, some water to be evaporated, and moisture level to be reduced. A domestic microwave oven works by passing microwave radiation, usually at a frequency of 2450 MHz (a wavelength of 12.24 cm), through the food. Water, fat, and sugar molecules in the food absorb energy from the microwave beam in a process called dielectric heating. Many molecules (such as water) are electric dipoles, meaning that they have a positive charge at one end and a negative charge at the other, and therefore rotate as they try to align themselves with the alternating electric field induced by the microwave beam. This molecular movement creates heat by friction as the rotating molecules hit other molecules and put them into motion.

Microwave heating is most efficient on liquid water, and much less so on fats and sugars (which have less molecular dipole moment), and frozen water (where the molecules are not free to rotate). Large industrial/commercial microwave ovens operating in the 900 MHz range also heat water and food perfectly well. The power generated in a material is proportional to the frequency of the source, the dielectric loss of the material, and the square of the field strength within it. The microwave heating rates and potential non-uniformity are functions of oven factors and load characteristics (size, shape, dielectric properties, etc.).

In conventional heating, heat is transferred to the surface of the material to be heated by conduction, convection, and/or radiation, and into the interior by thermal conduction. In contrast, in dielectric heating, heat is generated directly inside the material, making possible higher heat fluxes and thus a much faster temperature rise than in conventional heating. However, heat conduction still plays an important role when heating thick samples by dielectric heating and for equilibrating temperatures when heat generation is uneven.Depending on water content the depth of initial heat deposition may be several centimeters or more with microwave ovens, in contrast to grilling, which relies on infrared radiation, or the thermal convection of a convection oven, which deposit heat shallowly at the food surface. Depth of penetration of microwaves is dependent on food composition and the frequency, with lower microwave frequencies being more penetrating. The heat generated per unit volume of material (Q) is the conversion of electromagnetic energy in to heat energy. Its relationship with the average electric field intensity (Erms) at that location can be derived from Maxwell’s equations of electromagnetic waves as shown by Metaxax and Meredith (1983):

…(1)

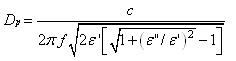

Where, f is the frequency of microwaves, Î0 is the dielectric constant of the free space (8.854 × 10−12 A2 s4/kg m3), and is the loss factor of the food being heated. At a given frequency, the dielectric loss factor is a function of the composition of the food materials and its temperature. Penetration depth (Dp) is another important factor in microwave heating. It is defined as the depth below the surface of the material where the power density of a plane electromagnetic wave decays by 1/e (37%) from the original value at the surface. The Dp is calculated as follows:

…(2)

…(2)

Where, c is speed of light in free space (3×108 m/s), is the frequency (Hz), is the loss factor of the food and is dielectric constant.

Microwaves

Microwaves are electromagnetic waves having wavelength (peak to peak distance) varying from 1millimeter to 1 meter. Frequency of these microwaves lies between 0.3 GHz and 3 GHz. Microwaves have greater frequency than radio waves so they can be more tightly concentrated. Microwaves propagate through air and space at about the speed of light. Microwaves can also be considered as electromagnetic force fields for better understanding of working of microwave oven. Microwaves interfere inside the microwave oven to produce high and low energy pockets. This can be explained by the phenomenon of resonance.

Mechanism of heating

In microwave heating or drying, the microwave-emitted radiation is confined within the cavity and there is hardly heat loss by conduction or convection so that the energy is mainly absorbed by a wet material placed in the cavity. Furthermore, this energy is principally absorbed by the water in the material, causing the temperature to rise, some water to be evaporated, and the moisture level to be reduced.

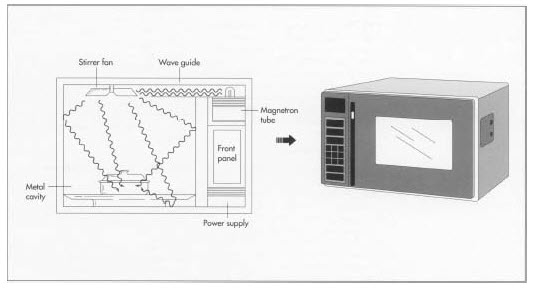

Microwave Oven

A microwave oven consists primarily of a magnetron, a magnetron control circuit (usually with a microcontroller), a waveguide and a cooking chamber (cavity). A cavity magnetron is a high-powered vacuum tube that generates coherent microwaves, and its theory of operation is based on the motion of electrons under the influence of combined electric and magnetic fields. A waveguide is a structure which guides waves, such as electromagnetic waves, light, or sound waves.

Fig 2. Schematic diagram of a microwave oven

A microwave oven works by passing microwave radiation, usually at a frequency of 2450 MHz (a wavelength of 12.24 cm), through the food. Water, fat, and sugar molecules in the food absorb energy from the microwave beam in a process called dielectric heating. Many molecules (such as those of water) are electric dipoles, meaning that they have a positive charge at one end and a negative charge at the other, and therefore rotate as they try to align themselves with the alternating electric field induced by the microwave beam. This molecular movement creates heat as the rotating molecules hit other molecules and put them into motion. Microwave heating is most efficient on liquid water, and much less so on fats and sugars (which have less molecular dipole moment), and frozen water (where the molecules are not free to rotate). Microwave heating is sometimes incorrectly explained as a rotational resonance of water molecules: such resonance only occurs at much higher frequencies, in the tens of gigahertz. Moreover, large industrial/commercial microwave ovens operating in the 900 MHz range also heat water and food perfectly well. The power generated in a material is proportional to the frequency of the source, the dielectric loss of the material, and the square of the field strength within it. The microwave heating rates and potential non-uniformity are functions of oven factors and load characteristics (size, shape, dielectric properties, etc.). Heat is also generated by another mechanism. Food material also contains ions (charged molecules) which accelerate in electric fields. Force on such ion is given by

![]() … (1)

… (1)

where, is the force vector acting on the ion,q is the charge on the ion and is the electric field applied

A common misconception is that microwave ovens cook food from the "inside out". In reality, microwaves are absorbed in the outer layers of food in a manner somewhat similar to heat from other methods. The rays from a microwave electrically manipulate water particles to cook food. It is actually the friction caused by the movement that creates heat and warms the food. The misconception arises because microwaves penetrate dry nonconductive substances at the surfaces of many common foods, and thus often deposit initial heat more deeply than other methods. Depending on water content the depth of initial heat deposition may be several centimeters or more with microwave ovens, in contrast to grilling, which relies on infrared radiation, or the thermal convection of a convection oven, which deposit heat shallowly at the food surface. Depth of penetration of microwaves is dependent on food composition and the frequency, with lower microwave frequencies being more penetrating.

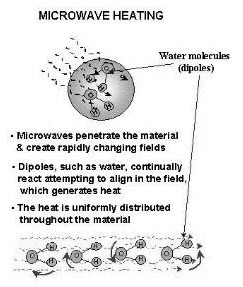

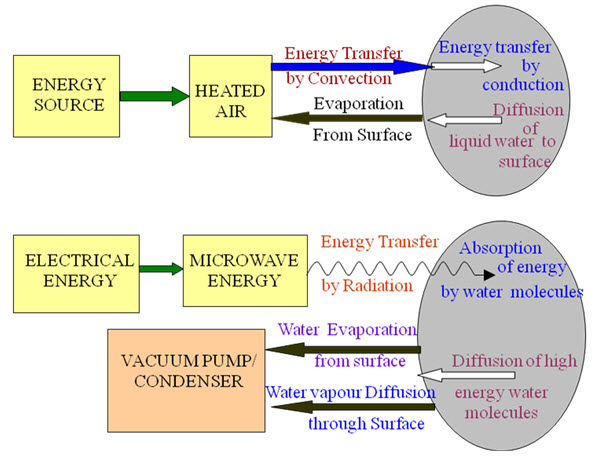

Fig. 3. Heating effect of microwaves

In microwave heating, microwaves penetrate to the interior of food and heat is generated by absorption of electromagnetic radiation by dipolar molecules like water and fat present in foods to be heated. The microwave radiation is transformed into kinetic energy, which makes water molecules vibrate intensively causing friction and leading to rapid increase in temperature and consequently efficient water evaporation. This results in a greatly increased vapor pressure differential between the center and surface of the product, allowing fast transfer of moisture out of the food. Hence, microwave drying is rapid, more uniform and energy efficient compared to conventional hot air drying. The problems in microwave drying, however, include product damage caused by excessive heating due to poorly controlled heat and mass transfer [29,30]. Gunasekaran [31] proposed two strategies to apply microwaves effectively for drying and they are by creating a vacuum in the dryer to lower the drying temperature and applying microwave in a pulsed manner to maximize drying efficiency. In recent years, microwave-vacuum drying (MVD) has been investigated as a potential method for obtaining high quality dried food products. Microwave-vacuum drying combines the advantages of both vacuum drying and microwave heating. The low temperature and fast mass transfer conferred by vacuum combined with rapid energy transfer by microwave heating leads to rapid and low temperature drying and thus it has the potential to improve energy efficiency and product quality. Some foods have been successfully dried by microwave-vacuum drying techniques. The effect of vacuum in microwave drying operation is system specific and for successful design and operation of an industrial microwave-vacuum drying system, knowledge of the drying characteristics of the material under different conditions is important [32,33,34]. This reduces the time required for complete drying by more than 30% as compared to conventional methods [35]. Some researchers have reported the microwave vacuum drying studies of foods like garlic, carrots, potato, and parsley root and showed that microwave vacuum drying can be used to dry the foods for better product quality [21, 36,37,38,39,40].

Another approach to use microwaves is combining them with conventional hot air drying. Microwaves help to enhance the rate of moisture removal during hot air drying by evaporating moisture within product that generates additional pressure gradient for moisture movement. Researchers have attempted microwave convective drying of carrots, potatoes, garlic and onions. Bouraoui et al. [42] dried potato slices using combined microwave and convective drying and concluded that microwave drying had a potential for producing better quality dried product than convective drying alone. The drying time was reduced considerably that is 10 min with microwave-convective drying as compared to 10 h in convective drying. No case hardening was observed and shrinkage was less than that found in convective drying. Pravanjan et al. [43] evaluated the drying characteristics of carrot cubes by microwave hot air drying and reported that the microwave drying results in a substantial decrease (25-90%) in the drying time and better product quality than conventional hot air drying. Sharma and Prasad [44] dried garlic cloves by combined microwave convective drying technique. They reported that the microwave convective drying results in saving to an extent of about 91% of total drying time. Good quality dried garlic cloves were also obtained by the microwave convective drying technique. The details of microwave drying of various foods are given in Table 3.

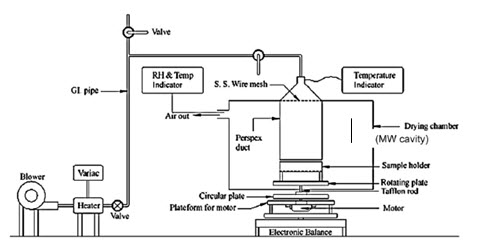

Figure 14 Experimental setup for microwave vacuum drying of carrot slices

Types of Microwave Dryers

Microwaves can be combined with different types of dryers to accelerate the drying rate. Following combinations are available with microwaves:

-

Microwave vacuum dryer

-

Microwave convective dryer

-

Microwave freeze dryers

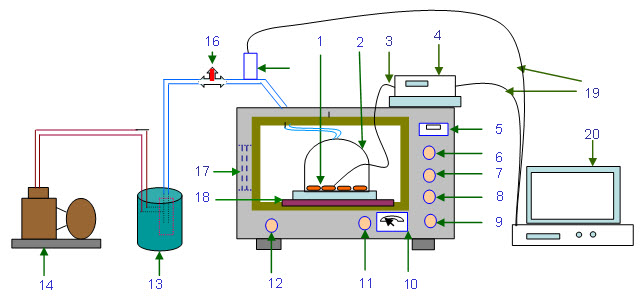

Several researchers in the developed and developing countries have done studies on microwave assisted drying of various fruits and vegetable and reported that the drying by microwave assisted convective and microwave vacuum methods is more efficient than conventional drying techniques. Some researchers (Shivhare et al., 1992; Sharma and Prasad, 2001) have reported microwave assisted hot air drying of foodstuffs and found considerable improvements in the drying process and quality of dehydrated products. The simple laboratory microwave convective dryer for foodstuffs is shown in Fig.1.

Fig. 1 Schematic diagram of microwave convective dryer (Sharma and Prasad, 2001)