Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Lesson 22. Types of spoilage in storage

22.1 Introduction

Post-harvest spoilage may occur in the following areas:

during harvesting

during transportation

during drying

during threshing

during processing

during storage

This chapter is concerned primarily with spoilage which occur during storage. Such losses do not only result from the effects of moisture, heat and pests. The following factors are also of importance:

The previous history of the stored produce as well as the growing conditions before harvesting, any field infestation with pests or fungi or any heat damage which may have occurred during the drying process.

Genetic differences, i.e. differences specific to certain varieties and species with regard to tolerance against storage pest

22.2 Types of Spoilage

22.2.1 Losses in quantity

Losses in quantity of the stored produce result from grain being spoilt or running out from damaged bags, from theft or from the grain being damaged by pest organisms. Losses in weight may also result from changes in the grain moisture content during the storage period. Due to the following reasons, it is generally difficult to evaluate the exact extent of losses in quantity:

There is no method of calculating losses which is simple, quick, reliable and generally applicable at the same time.

The exact amount of harvested produce is often not known, particularly in small farm storage, so that losses may be registered at a later date but not quantified.

in the case of infestation with insects, the loss in weight in no way corresponds to the difference in weight before and after infestation. When weighing the produce, leftovers, grass, webbing, pest carcasses and rodent droppings are also weighed. Assuming that this filth cannot be separated from the produce, the actual losses are higher than those calculated.

Estimating Losses

The most simple method of establishing losses in the store is to record the amounts entering and leaving the store (weigh-in, weigh-out method), even though the results achieved using this method are not always satisfactory for the reasons and shortcomings mentioned above.

It is also possible to make use of other methods of estimating losses, out of which the count and weigh method (C&W) is fairly easy to apply in small farm storage.

By establishing the number and weight of damaged and undamaged grains of a composite sample (e.g. 1000 grains) at monthly intervals, changes in the weight of stored produce can be determined over a period of storage.

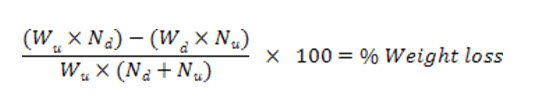

The loss in weight in per cent is calculated using the following equation:

Wu=weight of undamaged grains, g

Nu=number of undamaged grains, g

Wd=weight of damaged grains, g

Nd = number of damaged grains, g

Shortcomings in this count and weigh method become apparent particularly:

when there are large variations in grain size

when grain is so heavily infested, that kernels cannot be counted any more because of complete destruction

When infestation inside the grains occurs this cannot be detected so that attacked grains are classified as “undamaged”.

Other applicable methods for the estimation of storage losses are the Thousand Grain Mass Method (TGM) and the Standard Volume Weight Method (SVM).

The Thousand grain mass (TOM) method

Basic Principle

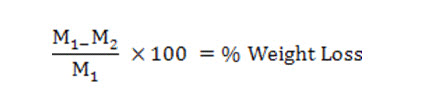

When an entire lot of grain is weighed before and after being attacked by insect pests, microorganisms or some other causing agent, the percentage loss of mass is easily calculated by using the formula:

where:

M1 = Grain mass before attack

M2 = Grain mass after attack

"Mass" in this context refers to the dry matter weight.

A sample taken from the lot in strict accordance with representative sampling principles should possess all the characteristics of the grain in proportion to their ccurrence in the lot at the time of sampling. Therefore, if the lot consists of 40% large grains, 50% medium size grains and 20% small grains, these proportions should be found in representative samples. Likewise if 7% of the grains in the lot are damaged, this percentage of damaged grains should also be found in the representative sample.

It is important that the mass per standard unit of a representative sample should be the same as the mass per standard unit of the entire lot of grain at the time of sampling. A reduction in the value of this unit between two sampling occasins should be proportional to a dry weight loss in the grain lot and should therefore provide a means of estimating the loss.

22.2.2 Losses in quality

Losses in occur in various forms:

changes in colour (e.g. yellowing of rice)

changes in smell

changes in taste

loss in nutritional value (degradation of proteins and vitamins)

loss in cooking, milling or baking quality

contamination of stored produce with mycotoxins or pathogenic agents

loss of germination power in seeds

Often several qualitative changes occur at the same time, usually also in connection with weight losses. Losses in quality are much more difficult to assess than losses in quantity, as they cannot always be easily recognized (e.g. loss in nutritional value). Additionally in many countries there is a lack of quality standards and quality changes may be assessed differently by individual consumers.

22.2.3 Longevity

The viability-period of a grain during storage can be short or long. The grain dies owing to the degeneration of protein which, in turn, is influenced by decay of components in the cell nucleus. Generally, the life of a stored grain regulated by the grain-type, the seed-borne micro flora, and by the interaction between temperature and moisture.

22.2.4 Sprouting

Sprouting of the grain during storage occurs mainly owing to generation of heat as a result of infestation. A grain sprouts only when its moisture content exceeds certain limit of moisture content of 30-35%.

References:

Anonymous (1985), Prevention of Post-Harvest Food Losses, FAO, Rome, 121 pp.

Boxall, R.A. (1986), A critical review of the methodology for assessing farm-level grain losses after harvest, TDRI, Slough, 139 pp.

Hall, D.W. (1970), Handling and Storage of Food Grains in Tropical and Subtropical Areas.