Site pages

Current course

Participants

General

Module 1. Classification of Farm Power Sources

Module 2. Classification of IC Engines & Therm...

Module 3. Performance Characteristics

Module 4. Engine Components

Module 5. Engine Operating System

Module 6.:Engine Fuel System

Module 7. Engine Governor

Module 8. Engine Cooling & Lubrication system

Module 9. Engine Ignition System

26 April - 2 May

LESSON 15. Turbochargers & Superchargers

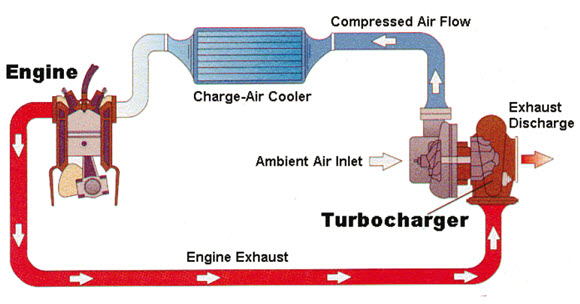

15.1 Turbocharger : It is a centrifugal compressor driven by turbine which is run by exhaust gases to compress incoming air into the engine. With increased pressure, the weight or amount of fuel entering the same space inside the engine is increased. In this way, the burning of fuel is more efficient inside the engine chamber and it eventually results in greater performance of the vehicle from the same displacement of engine without need of a larger displacement engine.

Exhaust gases contain a significant portion i.e around 30% of heat energy being generated due to burning of fuel. In turbocharger, exhaust gasses are used to drive a compressor which has following advantages to be used in diesel engines.

i) Engine output power is increased for a given engine displacement and has better Power/Weight ratio

ii) Engine torque characteristics are enhanced

iii) Better engine performance at higher altitudes

iv) Better fuel economy and exhaust gas emission

15.2 Superchargers: The device (compressor) powered by crankshaft used to compress incoming air of the engine is called supercharger. Supercharger is used to increase the volumetric efficiency of an engine by feeding both air and fuel at high pressure. The supercharger is driven directly by the engine through belts, the response of the same is instantaneous and a sudden increase in power can be obtained. Generally, in the natural aspirated engines, the charge is sucked in the cylinder by the vacuum created due to downward motion of the piston in the cylinder. With supercharger, the charge is induced with pressure which increases the density of the charge and hence the weight of charge per stroke is increased. As the weight of charge is increased , the power output also increase upto extent of 40% with supercharging.

At higher altitude, since the air gets thinner, the need of supercharger increases at it compensates the air intake by making relatively denser/heavier air into the cylinder during the suction stroke. Since, the supercharger increases the pressure, engine must be able to sustain the higher forces and also the fuel being used to have better anti-knock properties. However, in petrol engines when density of fuel is increased keeping the fuel of same octane number, the compression ratio is to be decreased to avoid detonation. But, with decrease in compression ratio, the thermal efficiency also decreases which is not preferred. Following are the three types of superchargers are being used.

i) Centrifugal supercharger

ii) Vane supercharger

iii) Root’s supercharger

Centrifugal supercharger : This is one of the most commonly used supercharger which is driven by belt and pulley. The air fuel mixture enters into the impeller of the supercharger where this mixture is supercharged with pressure using the kinetic energy. The impeller runs at sufficiently high speed of around 80000 rpm. The impellers are made of special material like alloy steel which can with stand the high stress being generated due to such a high speed of impellers.

Vane supercharger : The rotating drum of supercharger is mounted with number of vanes which are made of laminates of linen or tufnol as these material have low friction, low coefficient of thermal expansion and also run without making any noise. As the drum rotates, the space between the body and drum decreases from inlet to outlet which decreases the volume and increase the pressure at outlet.

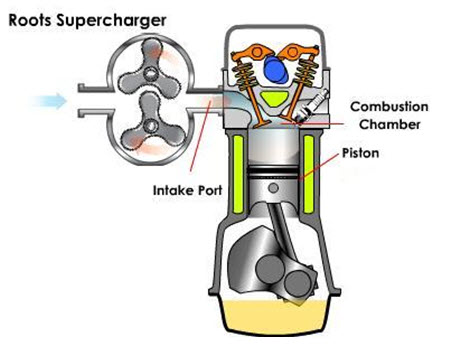

Root’s supercharger : This consist of two rotors of epicycloid shape which are connected with each other by gear of same size to make these rotors run at same speed to generate pressure in the mixture coming out from the outlet just like it happens in gear type pumps.

Although turbochargers are similar to superchargers as far as the purpose of their usage is concerned. Both are used for increasing the density of air intake in the engine. But the major functional difference lies in their mode of driving mechanism. Turbochargers are driven by the exhaust gasses whereas the superchargers are directly driven by the bet pulley mechanism by taking a portion of power out of an engine. Although, superchargers are easier to install, but it costs more.