Site pages

Current course

Participants

General

MODULE 1.

MODULE 2.

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

MODULE 9.

MODULE 10.

LESSON 1. INTRODUCTION TO MACHINE DESIGN

1.1 What is Design?

The word ‘design’ can either be a noun or a verb. As a noun, ‘Design’ can be referred to an object’s aesthetic appearance as well as its function. For example, ‘a beautifully designed dress’ refers to its appeal to our visual perception, and ‘a nicely designed car engine that gives very good mileage and performance’ refers to the concept of function. As a verb, ‘Design’ is the act of formalizing an idea or concept into concrete information. It includes the processes of conception, invention, visualization, calculation, refinement and specification of details that determine the form of a product. Design may be defined as an iterative decision making process to formulate a plan by which resources are optimally converted into systems, processes or devices in order to solve a specific problem or to fulfill a specific need. It begins with a need, a problem, an idea or a concept and ends with concrete information, in the form of drawings, computer representation or in any other form, which helps in manufacturing and utilization of a product.

1.2 Phases of Design Process

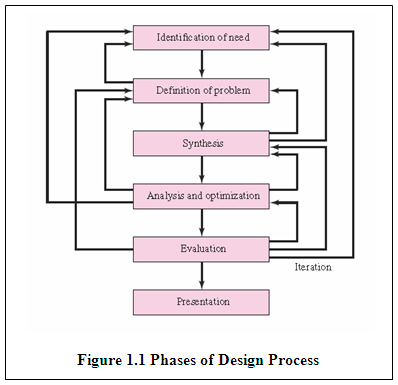

The design process begins with identification of a need and a decision to do something about it. After a number of iterations, the process ends with the presentation of the plans for satisfying the need. Depending on the nature of the design task, several phases may be repeated before the design is finalized. Complete design process can be explained with the help of Figure1.1, which shows the phases of design process and iterations.

1.2.1 Identification of Need

Design process generally starts with the identification of need, a problem or with the recognition of a potential market for a product, device or process. Recognition of the need requires a lot of imagination and creativity, because the need is generally not clear and evident and can be vague. It can be just a feeling of uneasiness or a sensing that something is wrong. For example, there is a need to do something about the design of a motor vehicle may be indicated by its low efficiency, lesser maximum speed or high noise and vibration levels. Then the need statement may say that the design of the motor vehicle needs an improvement.

1.2.2 Definition of Problem

Need statement is generally brief and doesn’t include the details. The definition of problem is more specific and includes all the specifications for the object to be designed, which include the input i.e. resources to be utilized, expected output, cost limitations, quantity required, expected life and reliability, temperature limitations, maximum range and expected variations in the variables, dimensional & weight limitations, manufacturing limitations etc. Anything that limits the designer’s freedom of choice is a constraint and all the constraints should be clearly defined in the problem definition.

Background information on all the relevant aspects of the problem should also be gathered. It includes the study to find out whether this, or a similar problem, has been solved before. If a ready-made solution is available in the market, it can be used. Or even if something new is to be done, the study of existing similar technologies, products, relevant patent literature and technical publications can be very helpful.

1.2.3 Synthsis

Synthesis is the process of concept generation, the purpose of which is to develop as many ideas as possible to offer potential solutions to the problem defined in previous phase. Primary need is identified for initial focus and then all feasible design alternatives are developed. Different proposed alternatives should not be compared with each other, in this phase, and each alternative should be separately evaluated on the basis of established criteria.

1.2.4 Analysis and Optimization

After synthesis, different proposed solutions are analyzed to assess their performance and can be ranked. Alternatives having unsatisfactory performance can either be revised and improved or discarded. It is always advisable to select two or three design concepts and develop them instead of selecting presumably the best one only. Concepts, with potential, are optimized to further increase their performance. Optimization is the repetitive process of refining a set of criteria, which are often conflicting, to achieve the best compromise. These competing design concepts can finally be compared again so that the path leading to the most competitive product can be chosen. For analysis and optimization, mathematical models are prepared to simulate the real physical system.

Synthesis, analysis and optimization go hand in hand. Identification of any kind of deficiency or inadequacy in the proposed solution, in the analysis and optimization phase, may require synthesis of some new solution and process keeps on repeating until an adequate and optimum solution is obtained.

1.2.5 Evaluation

In this phase, prototype model of the design is generally made and tested, which is the final evaluation of the design to make sure that it satisfies the original requirements. In addition to this, design is evaluated for its reliability, competitiveness, economic viability, maintenance requirements, profitability and so on.

1.2.6 Presentation

Final phase of the design process is to communicate the design to others. This presentation can be in the form of drawings, computer models on in any other form that would help in manufacturing and utilization of the product.

1.3 Machine Design

Machine is a combination of linkages having definite motion and capable of performing useful work. Machine Design is creation of plans for the machine to perform the desired functions. Machine design can be defined as creation of right combination of correctly proportioned moving and stationary components so constructed and joined as to enable the liberation, transformation and utilization of energy. Scientific principles, technical knowledge and imagination are used to develop a machine or mechanical system to perform specific functions with maximum economy and efficiency. It includes the creation of new better machines or improving the existing ones. Machine Design requires the knowledge of basic and engineering sciences such as Physics, Mathematics, Engineering Mechanics, Strength of Materials, Theory of Machines, Thermodynamics and Heat Transfer, Vibrations, Fluid Mechanics, Metallurgy, Manufacturing Processes and Engineering Drawing.

In machine design, the designer’s task is to determine the motion, forces and energy transfer involved so as to determine the sizes, shapes and materials for each element of the machine. When any component of machine ceases to perform its intended function, machine element or machine is said to have failed. Generally the machine elements are designed on the basis of strength and rigidity so that they are able to withstand the applied load with permissible deformation or stress. In addition to strength and stiffness, other factors that are considered in design of machine element are weight, cost, wear, safety, reliability etc. Design work may involve concentrating on one component at a time, but it is very important to simultaneously consider its relation with the other components and the product as a whole.

In machine design, as in any other kind of design, no standard procedure or rigid rules can be specified for the designer, but the following steps are generally followed:

Problem to be solved or desired purpose of the machine is completely and clearly stated.

Possible mechanisms that will provide the desired motion or set of motions are selected.

Forces acting on and energy transmitted by each element of the machine are determined.

Best suitable material is selected for each of the machine element.

Allowable values of stress and deflection are determined for each machine element, depending upon its material and functional requirements.

Size and shape of each machine element is determined so that it can withstand the applied loads without failure.

Dimensions of the machine elements are modified considering manufacturing aspects.

Assembly and detailed drawings of the machine are made with complete specification of materials and manufacturing methods.

1.4 Design Considerations

As discussed in the previous article, strength and stiffness are very important factors that are considered in machine design but there are a number of other considerations that the designer has to keep in mind while designing any product. Some of the important factors considered in design are listed below:

- Functionality

- Strength

- Stiffness

- Wear

- Corrosion

- Thermal Properties

- Surface Finish

- Lubrication

- Friction

- Weight

- Noise

- Shape

- Size

- Safety

- Reliability

- Manufacturability

- Utility

- Maintenance

- Liability

- Cost

- Life

- Styling

- Control

- Volume

- Marketability

- Remanufacturing

References

-

Design of Machine Elements by VB Bhandari

-

Mechanical Engineering Design by J.E. Shigley

-

Analysis and Design of Machine Elements by V.K. Jadon

-

Machine Design by R.S. Khurmi

-

Mechanical Design by Peter Childs

-

Engineering Design by G.E. Dieter

-

Machine Design by PC Sharma & DK Aggarwal