Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 12. Biogas plants types

Most organic materials undergo a natural anaerobic digestion in the presence of moisture and absence of oxygen and produce biogas. The biogas so obtained is a mixture of methane (CH4): 55-65% and Carbon dioxide (CO2): 30-40%. The biogas contains traces of H2, H2S and N2. The calorific value of biogas ranges from 5000 to 5500 Kcal/Kg (18.8 to 26.4 MJ /m3). The biogas can be upgraded to synthetic natural gas (SNG) by removing CO2 and H2S. The production of biogas is of particular significance in India because of its large scale cattle production. The biogas is used for cooking, domestic lighting and heating, run I.C. Engines and generation of electricity for use in agriculture and rural industry. Family biogas plants usually of 2-3 m3 capacity.

Advantages

-

The initial investment is low for the construction of biogas plant.

-

The technology is very suitable for rural areas.

-

Biogas is locally generated and can be easily distributed for domestic use.

-

Biogas reduces the rural poor from dependence on traditional fuel sources, which lead to deforestation.

-

The use of biogas in village helps in improving the sanitary condition and checks environmental pollution.

-

The by-products like nitrogen rich manure can be used with advantage.

-

Biogas reduces the drudgery of women and lowers incidence of eye and lung diseases.

Raw materials for biogas generation Biogas is produced mainly from

-

Cow dung

-

Sewage

-

Crop residues

-

Vegetable wastes

-

Water hyacinth

-

Poultry droppings

-

Pig manure

Digestion is biological process that occurs in the absence of oxygen and in the presence of anaerobic organisms at temperatures (35-70ºc) and atmospheric pressure. The container in which, this process takes place is known as digester.

Anaerobic digestion:

The treatment of any slurry or sludge containing a large amount of organic matter utilizing bacteria and other organisms under anaerobic condition is commonly referred as anaerobic digestion or digestion. Anaerobic digestion consists of the following three stages. The three stages are (i) the enzymatic hydrolysis, (ii) acid formation and (iii) methane formation.

Enzymatic hydrolysis

In this stage, a group of facultative microorganisms acts upon the organic matter and convert insoluble, complex, high molecular compounds of biomass into simple, soluble, low molecular compounds. The organic substances such as polysaccharide, protein and lipid are converted into mono-saccharide, peptide, amino acids, and fatty acids. Then they are further converted into acetate, propionate and butyrate.

Acid formation

The micro organisms of facultative and anaerobic group collectively called as acid formers, hydrolyze and ferment the productions of first phase i.e., water soluble substances into volatile acid. The major component of the volatile acid is the acetic acid. In addition to acetate or hydrogen and carbon dioxide, some other acids like butyric acid and propionic acid are also produced.

Methane formation

Finally, acetate or hydrogen plus carbon dioxide are converted into gas mixture of methane (CH4) and CO2 by the bacteria, which are strictly anaerobes. These bacteria are called methane fermentators. For efficient digestion, these acid formers and methane fermentators must remain in a state of dynamic equilibrium. The remaining indigestible matter is referred as “slurry”. The following are some approximate rules used for sizing biogas plants or for estimating their performance:

-

One kg of dry cattle dung produces approximately 1 m3 of biogas.

-

One kg of fresh cattle dung contains 8% dry biodegradable mass.

-

One kg of fresh cattle dung has a volume of about 0.9 liters.

-

One kg of fresh cattle dung requires an equal volume of water for preparing slurry.

-

Typical retention time of slurry in a biogas plant is 40 days.

The efficiency of biogas generation depends upon the following factors:

-

Acid formers and methane fomenters must remain in a state of dynamic equilibrium, which can be achieved by proper design of digester.

-

Anaerobic fermentation of raw cow dung can takes place at any temperature between 8 and 55°C. The value of 35°C is taken as optimum. The rate of biogas formation is very slow at 8°C. For anaerobic digestion, temperature variation should not be more than 2 to 3°C. Methane bacteria work best in the temperature range of 35 and 38°C.

-

A pH value between 6.8 and 7.8 must be maintained for best fermentation and normal gas production. The pH above 8.5 should not be used as it is difficult for the bacteria to survive above this pH.

-

A specific ratio of carbon to nitrogen (C/N ration) must be maintained between 25:1 and 30:1 depending upon the raw material used. The ratio of 30:1 is taken as optimum.

-

The water content should be around 90% of the weight of the total contents. Anaerobic fermentation of cow dung proceeds well if the slurry contains 8 to 9% solid organic matter.

-

The slurry should be agitated to improve the gas yield.

-

Loading rate should be optimum. If digester is loaded with too much raw material, acids will accumulate and fermentation will be affected.

Types of biogas plants: Biogas plants basically are two types.

Floating dome type

Eg. KVIC-type (KVIC- Khadi Village Industries Commission)

Fixed dome type

Eg. Deenabandu model

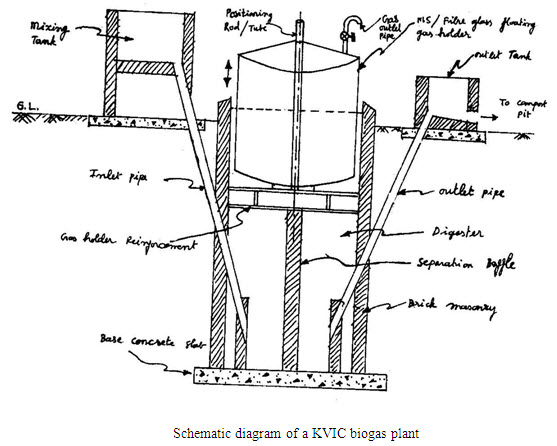

KVIC type biogas plant

This mainly consists of a digester or pit for fermentation and a floating drum for the collection of gas. Digester is 3.5-6.5 m in depth and 1.2 to 1.6 m in diameter. There is a partition wall in the center, which divides the digester vertically and submerges in the slurry when it is full. The digester is connected to the inlet and outlet by two pipes. Through the inlet, the dung is mixed with water (4:5) and loaded into the digester. The fermented material will flow out through outlet pipe. The outlet is generally connected to a compost pit. The gas generation takes place slowly and in two stages. In the first stage, the complex, organic substances contained in the waste are acted upon by a certain kind of bacteria, called acid formers and broken up into small-chain simple acids. In the second stage, these acids are acted upon by another kind of bacteria, called methane formers and produce methane and carbon dioxide.

Gas holder

The gas holder is a drum constructed of mild steel sheets. This is cylindrical in shape with concave. The top is supported radically with angular iron. The holder fits into the digester like a stopper. It sinks into the slurry due to its own weight and rests upon the ring constructed for this purpose. When gas is generated the holder rises and floats freely on the surface of slurry. A central guide pipe is provided to prevent the holder from tilting. The holder also acts as a seal for the gas. The gas pressure varies between 7 and 9 cm of water column. Under shallow water table conditions, the adopted diameter of digester is more and depth is reduced. The cost of drum is about 40% of total cost of plant. It requires periodical maintenance. The unit cost of KVIC model with a capacity of 2 m3/day costs approximately Rs.14, 000 - 00. Fig. 1. Schematic diagram of a KVIC biogas plant

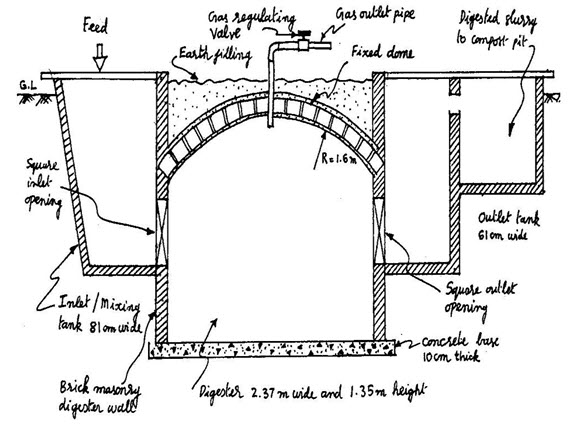

Janata type biogas plant:

The design of this plant is of Chinese origin but it has been introduced under the name “Janata biogas plant” by Gobar Gas Research Station, Ajitmal in view of its reduced cost. This is a plant where no steel is used, there is no moving part in it and maintenance cost is low. The plant can be constructed by village mason taking some pre-explained precautions and using all the indigenously available building materials. Good quality of bricks and cement should be used to avoid the afterward structural problems like cracking of the dome and leakage of gas. This model have a higher capacity when compared with KVIC model, hence it can be used as a community biogas plant. This design has longer life than KVIC models. Substrates other than cattle dung such as municipal waste and plant residues can also be used in janata type plants. The plant consists of an underground well sort of digester made of bricks and cement having a dome shaped roof which remains below the ground level is shown in figure. At almost middle of the digester, there are two rectangular openings facing each other and coming up to a little above the ground level, act as an inlet and outlet of the plant. Dome shaped roof is fitted with a pipe at its top which is the gas outlet of the plant. The principle of gas production is same as that of KVIC model. The biogas is collected in the restricted space of the fixed dome, hence the pressure of gas is much higher, which is around 90 cm of water column.

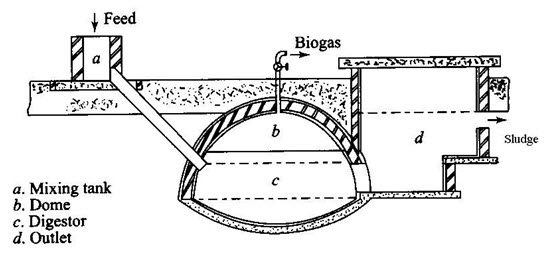

Deenbandhu biogas plant :

Deenbandhu model was developed in 1984, by Action for Food Production (AFPRO), a voluntary organization based in New Delhi. Schematic diagram of a Deenabandhu biogas plantentire biogas programme of India as it reduced the cost of the plant half of that of KVIC model and brought biogas technology within the reach of even the poorer sections of the population. The cost reduction has been achieved by minimizing the surface area through joining the segments of two spheres of different diameters at their bases. The cost of a Deenbandhu plant having a capacity of 2 m3/day is about Rs.8000-00. The Deenbandhu biogas plant has a hemispherical fixed-dome type of gas holder, unlike the floating dome of of the KVIC-design is shown. The dome is made from pre-fabricated ferrocement or reinforced concrete and attached to the digester, which has a curved bottom. The slurry is fed from a mixing tank through an inlet pipe connected to the digester. After fermentation, the biogas collects in the space under the dome. It is taken out for use through a pipe connected to the top of the dome, while the sludge, which is a by-product, comes out through an opening in the side of the digester. About 90 percent of the biogas plants in India are of the Deenbandhu type.

Schematic diagram of a Deenabandhu biogas plant