Site pages

Current course

Participants

General

Module 1. Micro-irrigation

Module 2. Drip Irrigation System Design and Instal...

Module 3. Sprinkler Irrigation

Module 4. Fertigation System

Module 5. Quality Assurance & Economic Analysis

Module 6. Automation of Micro Irrigation System

Module 7. Greenhouse/Polyhouse Technology

Lesson 4. Types of Micro Irrigation Systems

The micro irrigation system can be classified in respect to variety of parameters. The micro irrigation encompasses several ways of water application to plants: drip, spray, subsurface and bubbler irrigation.

4.1 Drip Irrigation

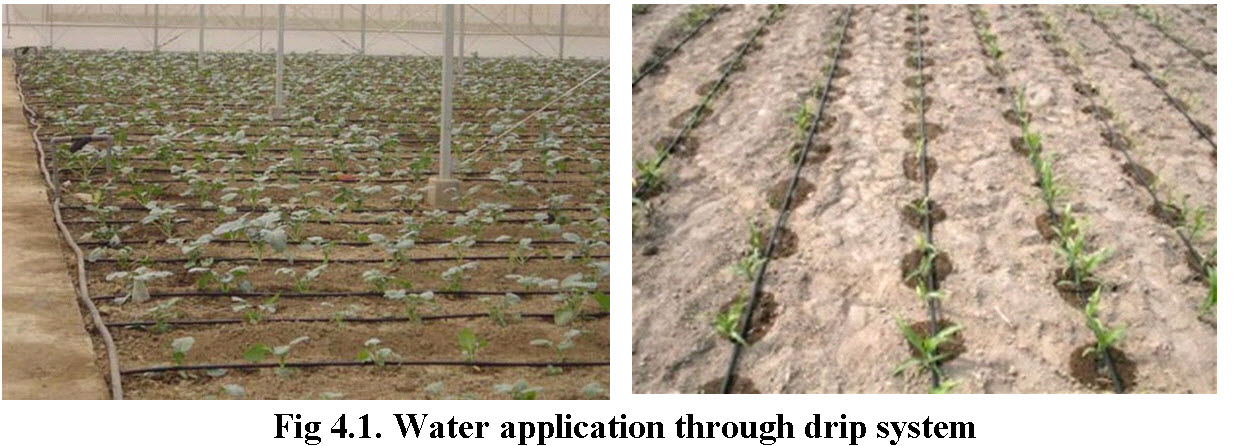

Drip or trickle irrigation is the newest of all commercial methods of water application. It is described as the frequent, slow application of water to soils through mechanical devices called emitters or applicators located at selected points along the delivery lines. The emitters dissipate the pressure from the distribution system by means of orifices, vortexes and tortuous or long flow paths, thus allowing a limited volume of water to discharge. Most emitters are placed on the ground, but they can also be buried (Fig 4.1). The emitted water moves within the soil system largely by unsaturated flow. The wetted soil area for widely spaced emitters will be normally elliptical in shape. Since the area wetted by each emitter is a function of the soil hydraulic properties, one or more emission points per plant may be necessary (Howell et al., 1980)

4.2 Spray Irrigation

Spray irrigation is a form of irrigation in which pressurized water is sprayed over plants to provide them with water. This type of irrigation is also sometimes called sprinkler irrigation, and it is very widely used all over the world. The spray irrigation sizes can be designed for all size of farms, ranging from a home sprinkler to keep a lawn green to industrial sized sprinklers used to irrigate crops.

The application of water by a small spray or mist to the soil surface, water travel through the air becomes instrumental in the distribution of water. In this category two types of equipment are in use viz., micro-sprayers and micro-sprinklers. Micro-sprayers and static micro jets are non-rotating type with flow rates ranging from 20 to 150 l/h, whereas, micro-sprinklers are rotating type with flow rates ranging from 100 to 300 l/h. Fig 4.2 shows operation of micro sprinkler for irrigating a flower bed.

Fig 4.2. Water application through micro sprinkler system

This system is similar to the way one may water lawn at home - stand there with a hose and spray the water out in all directions. The systems can simply be long hoses with sprinklers along the length or a center-pivot system that traverses a circle in the fields. With a spray irrigation system, the irrigation sprinklers may be fixed in place, or located on movable frames. Some sprinkler heads will only spray in one direction, requiring careful placement, while others will rotate as they spray, and delivering water across a broader area. Rotating heads are often preferred because it allows for the installation of a single sprinkler array to cover a big area.

The center-pivot systems have a number of metal frames (on rolling wheels) that hold the water tube out into the fields. Electric motors move each frame in a big circle around the field (the tube is fixed at the water source at the center of the circle), squirting water. The depth of water applied is determined by the rate of travel of the system. Single units are ordinarily about 1,250 to 1,300 feet long and irrigate about a 130-acre circular area. In high-pressure systems, there can be very big water guns along the tube.

A more "modern" alternative to the high-pressure water guns is the low-pressure sprinkler system. Here, water is gently sprayed downward onto plants instead of being shot high in the air. Low-pressure systems are more efficient in that much less water evaporates or is blown off the fields, if there is a strong wind present.

Sources of water for spray irrigation vary. The utilization of treated wastewater should be encouraged. This is an environmentally friendly choice which reduces the demand for fresh water, nourishes the plants, and reduces wastewater runoff into waterways. Treated wastewater can be used on ornamental crops and landscaping, but it may be banned for use on crops. The source of water can be from wells, reservoirs, rivers, lakes, and streams.

(Source: http://www.wisegeek.com/what-is-spray-irrigation.htm 17th Aug, 2012

http://ga.water.usgs.gov/edu/irsprayhigh.html 17th Aug, 2012)

4.3 Sub-Surface System

It is a system in which water is applied slowly below the land surface through emitters. Such systems are generally preferred in semi permanent/permanent installations.

Subsurface drip irrigation (SDI) is a low-pressure, high efficiency irrigation system that uses buried drip tubes or drip tape to meet crop water needs. SDI technologies have been a part of irrigated agriculture since the 1960s; with the technology advancing rapidly in the last two decades. A SDI system is a flexible and can provide frequent light irrigations. This is especially suitable for arid, semi-arid, hot, and windy areas with limited water supply. Farm operations also become free of impediments that normally exist above ground with any other pressurized irrigation system. Since the water is applied below the soil surface, the effect of surface infiltration characteristics, such as crusting, saturated condition of pounding water, and potential surface runoff (including soil erosion) are eliminated during irrigation. With an appropriately sized and well-maintained SDI system, water application is highly uniform and efficient. Wetting occurs around the tube and water moves out in all directions. Fig 4.3 shows moisture distribution through a sub surface drip system. Subsurface irrigation saves water and improves yields by eliminating surface water evaporation and reducing the incidence of disease and weeds. Water is applied directly to the root zone of the crop and not to the soil surface where most weed seeds winter over. As a result, germination of annual weed seed is greatly reduced, and lowers weed pressure on beneficial crops. In addition, some crops may benefit from the additional heat provided by dry surface conditions, producing more crop biomass, provided water is sufficient in the root zone. When managed properly, water and fertilizer application efficiencies are enhanced, and labor needs are reduced. Field operations are also possible, even when irrigation is applied.

(Source: Subsurface Drip Irrigation (SDI) by D. Reich, R. Godin, J.L. Chávez, I. Broner1 (3/09); http://www.ext.colostate.edu/pubs/crops/04716.html/ 17th Aug, 2012)

4.4 Bubbler System

In this system the water is applied to the soil surface in a small stream or fountain. The discharge rate for point source bubbler emitters is greater than the drip or subsurface emitters but generally less than 225 l/h. Since the emitter discharge rate generally exceeds the infiltration rate of the soil, a small basin is usually required to contain or control the water. Bubbler systems do not require elaborate filtration systems. These are suitable in situations where large amount of water need to be applied in a short period of time and suitable for irrigating trees with wide root zones and high water requirements.

(Source: http://shodhganga.inflibnet.ac.in/bitstream/10603/2209/12/12_chapter%202.pdf 16th Aug, 2012)

References:

-

Howell, T.A., D.S. Stevenson, F.K. Aljibury, H.M. Gitlin, I-Pai Wu, A.W. Warrick, and P.A.C. Raats. (1980). Design and Operation of Trickle (Drip) Systems. (Chapter in: Design and Operation of Farm Irrigation Systems (Jensen M.E.). ASAE Monograph 3. St. Joseph, MI.

-

http://www.wisegeek.com/what-is-spray-irrigation.htm 17th Aug, 2012

-

http://ga.water.usgs.gov/edu/irsprayhigh.html 17th Aug, 2012

-

http://shodhganga.inflibnet.ac.in/bitstream/10603/2209/12/12_chapter%202.pdf 16th Aug, 2012

Suggested Reading:

-

Michael A. M. (2010) Irrigation Theory and Practice, Vikas Publishing House Pvt. Ltd., Delhi

-

Howell, T.A., D.S. Stevenson, F.K. Aljibury, H.M. Gitlin, I-Pai Wu, A.W.

-

Warrick, and P.A.C. Raats. (1980). Design and Operation of Trickle (Drip)

-

Systems. (In Design and Operation of Farm Irrigation Systems Edited by Jensen M.E.). ASAE Monograph 3. St. Joseph, MI.