Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

MODULE 11. TESTING OF FARM MACHINES, RELATED TEST ...

MODULE 12. SELECTION AND MANAGEMENT OF FARM MACHIN...

LESSON 5. MOWERS AND WINDROWERS

Forage harvesting is more complex as compared to grain crops. Forage crop is of great bulk and mass, containing 70-80% water when first harvested. For storage it must be dried, either naturally or artificially, to a safe moisture content of about 20 to 25%. Due to low product value it limits the economic feasibility of mechanization of harvesting operation of forage crops. The mowers are used to cut the crop and windrow in the field, which is manually collected for further chopping.

The forage harvester consists of a combination of plant-cutting unit and a chopping unit and is called field forage harvester. The field forage harvester performs the functions of both row binder and silage cutter, as it severs the standing stalks from the ground and chops them into silage in one continuous operation in the field. It can be grouped into two according to the mechanism used to cut the crop viz. field choppers and flail harvesters.

Mower

The mower is a machine mainly used for harvesting grasses and forage crops. It cuts the stems of standing vegetation to make hay out of them. The mower cutter bar is capable of cutting the stems at 3-10 cm above the ground. There are different types of mowers used for cutting grass and forage crop such as cylinder, reciprocating, horizontal rotary and flail type mowers. According to the source of power, mowers can be classified as manually operated, animal-drawn, tractor-drawn and self-propelled. According to the mode of hitching, mowers can be classified as trailed type, semi-mounted and integral mounted type. Semi-mounted and integral-mounted mowers can be further classified as rear, mid and front-mounted. According to drive used, mowers can be classified as ground-driven, engine-driven and PTO driven. The conventional animal-drawn mower has the following main parts:

A cutter bar to cut the crop and separate it from uncut portion.

Power transmission unit to receive and transmit motion force.

Frame to support moving parts.

Wheels to transport and for operating the cutting mechanism, and

Auxiliary parts to lift and drop the cutter bar.

Classification of Mowers

The mowers on the basis of their cutting mechanism are classified as:

a) Finger-type cutter bar mower

Here the plant is pressed by the active knife against the fixed ledger-plate of the finger guard and sheared.

b) Under-knife mower

Double knife cutter bar with one knife fixed falls under this category. With this system one knife acts as ledger plate of the guard and the other performs the function of a normal reciprocating knife. These mowers are simple in construction and minimize the chances of blockage by dense crop and by small soil obstructions. However they are not suitable in stony fields.

c) Double cutter-bar mower

It is provided with two cutter-bars which operate in opposite directions. The plants are sheared by the two active blades instead against the ledger plate of guard. Such mowers have advantages of minimum power requirement clean cut, higher speed of operation, cutting close to the ground etc. The cutter-bar mowers are further classified on the basis of their finger spacing.

(i) Normal cutter-bar: In these mowers the spacing of guard fingers and knife sections is kept equal to 76.2 mm. These mowers are most suitable for thick stemmed crops like jowar, maize, bajra etc.

(ii) Medium fine cutter-bar: In this type of cutter-bar the finger spacing is reduced from 76.2 mm to 50.00 mm and the knife spacing is kept constant to 76.2 mm. This mechanism helps better cutting in dense crops.

(iii) Fine cutter-bar: Here the finger spicing are kept 38.1 mm and the knife spacing remains 76.2 mm. This mechanism is especially suitable for the grasslands to harvest fine stemmed plants on broken terrain.

(d) Mower-cum-crusher

To perform cutting and condition operation the reciprocating mower is provided with a conditioning attachment. Such mowers are called mower-cum-crushers.

(e) Disc mowers

In these machines the plants are cut by the revolving blade in horizontal plane fitted on round discs. On the basis of their construction these mowers are further classified as:

(i) Drum Disc Mower: These mowers are provided with drum type discs, i.e. a drum is fitted over the disc to enable the cut material to push back to place it in the swath.

(ii) Rafter-disc Mower: These mowers are similar to the drum disc mowers except that (a) the power to the disc is transmitted through the system located below the disc and (b) the cut material is pushed back by the revolving discs and not by the drums as in the previous case. The discs are provided with throw-away pieces which help pushing back the cut material.

Rotary Mower

It consists of a single high speed cutting element in horizontal plane (60-70 m/s) and relies primarily upon the inertia of the material being cut to furnish the opposing force required for shear. The ground also acts as one of the shearing elements. It works on the principle of free-cutting. When a revolving blade hits, the plant, it is sheared and carried with the blade. The normal component of the force cuts the stalk and the tangential component helps imparting kinetic energy to the plant so as to carry it along with the blade up-to certain distance. The forward velocity component also helps adding to the magnitude of both the four components.

The rotary mowers are also of two types: (i) Disc-type mower and (ii) The Rotary stalk-cutter and shredder. The disc type mower has 2-3 swinging blades of approximately 75 mm x 40 mm x 3 mm size fitted to the disc. The diameter of the disc and number of the discs depends upon the swath width. Owing to the rotary speed of the disc and forward speed of the tractor, the blade travels in a cycloid-path. The tangential component of the force is much higher in magnitude than the radial component; as such the material is cut but not carried away from the cut area. The throw-away pieces are provided on the cylinder and/or on the discs to throw the cut material rearwards. The rotary cutter and shredder consist of two swinging knives rotating in a horizontal plane and housing. The rotating knives cut the material by impact and shear force. The material is carried to the discharge end by virtue of the kinetic energy imparted by the cutting blade.

Flail Mower

The flail mower cuts the plants, chops for them into small feed lengths and blows the cut and chopped material into the accompanying trailer. These machines are used for harvesting the crop for daily consumption or for silage making. The chopped lengths of the stalks can be varied from fine-medium to course by increasing or decreasing the clearance between the shear-bar and the flail-tip. The above machine can also be used for forge conditioning required to increase the drying rate during hay making process.

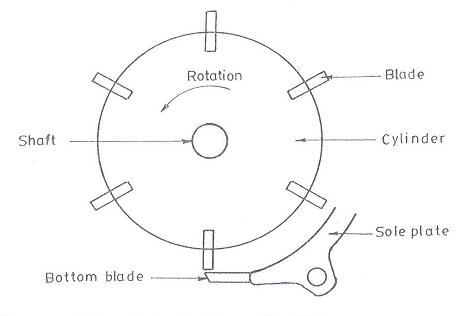

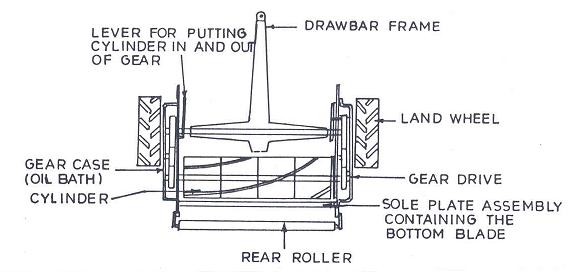

Cylinder Type Mower: It is generally used for lawn mowing. It includes lawn mowers and gang mowers. It could be hand-propelled and self-propelled lawn mowers and tractor-drawn and tractor-mounted gang mowers. It has rotating helical blades arranged in horizontal plane (Figs. 1 & 2). There are three gangs in this mower having 3-4 helical blades each supported over vertical discs. The rotors of this type of mowers are supported on ball bearings at each end. With the rotation of blades, forage or grasses are cut for example lawn mower. It can cover about 1.5-2.0 ha/h at a speed of 8-10 km/h.

Fig. 1: Side view of a cylinder mower.

Rotating Disc-type Mowers: There are two types of disc mowers. In one type, there are discs on the periphery of which free-swinging knives (2-4 in numbers) are attached. Sometimes the rotating knives are mounted on bearings on a cutter bar similar to one used for a conventional reciprocating mower. Cutting in this type of mower takes place due to impact and as such energy requirements are comparatively low. In drum-type mowers, usually there are two large-diameter moving drums. These are driven by belt and pullet system. Three to four steel blades are attached to each disc, which revolve at a speed of about 2000-rpm. The diameter of disc ranges from 60 to 80 cm. In this one also, cutting takes place due to impact. These types of mowers make fairly good swaths and the harvested material is dried speedily. Due to absence of gear or chain drive, the action is usually quite smooth and power consumption low.

Fig. 2: A view of gang mower.

Adjustments of mower reaper

|

Sr. No. |

Part |

Problem |

Adjustment |

|

1. |

Reel |

i) Does not rotate

ii)Improper gathering of crop |

i) Check tension of reel belt. Reel by hand to ensure that the drive pulley key and belt are secured. ii) Adjust height according to height of crop |

|

2. |

Cutter bar |

Unsatisfactory cutting |

i) Reduce forward speed ii) Correct the registration iii) Sharpen the knife sections or replace if worn out. iv) Check drive belt tension. If loose, tighten |

Windrowers

In some areas, farmers find that cutting and windrowing the top portion of the plants with the grain attached permit earlier harvesting and protect the grain under the following conditions.

(i) When the grain is unevenly ripened.

(ii) When fields are weedy.

(iii) When the straw is green but the crop is ripe.

(iv) When the grain is high in moisture.

(v) When crop conditions are such that legume crops tend to shatter if left until ripe, and

(vi) When weather conditions delay direct combining. The windrowing machine consists of a power-takeoff-driven knife, platform canvas, and reel.

The heads of grain are clipped off and fall upon the travelling platform canvas, which delivers the grain over one end onto the stubble. Most windrowing machines deliver the grain over the end farthest away from the standing grain. Center-delivery machines are available.

Self-Propelled Windrowers

Self-propelled windrowers consist of two types of headers. The augur cross feed is the most common type on hay machines but is too aggressive for grain. The draper type is employed on windrowers intended for both grain and hay. The maximum width that should be cut with a hay windrower is limited primarily by the maximum size of windrow that will cure in an acceptable time. Windrowers with cutting widths of 3.65 m and 4.25 m are popular in irrigated areas where hay yields per cutting are usually 2.2 to 3.4 Mg of dry matter per ha. Knife speeds are about the same as on mower-conditioners but strokes are often 6 to 10 mm greater than the 76.2 mm guard spacing. Chrome-plated knife sections are used almost universally. Conditioning attachments are usually 0.9 to 1.4 m wide, but the direct-feed, full-width-conditioner system of pull-type mower-conditioners has also been applied to some 2.75 m self-propelled machines.