Site pages

Current course

Participants

General

Module 1. Micro-irrigation

Module 2. Drip Irrigation System Design and Instal...

Module 3. Sprinkler Irrigation

Module 4. Fertigation System

Module 5. Quality Assurance & Economic Analysis

Module 6. Automation of Micro Irrigation System

Module 7. Greenhouse/Polyhouse Technology

Lesson 30. General Criteria for Construction

30.1 Site Selection

A greenhouse is designed to withstand local wind, snow and crop loads for a specific cropping activity. In this way, the structure becomes location and crop specific. The building site should be as level as possible to reduce the cost of grading, and the site should be well aerated and should receive good solar radiation. Provision of a drainage system is always possible. It is also advisable to select a site with a natural windbreak. In regions, where snow is expected, trees should be 30.5 m away in order to keep drifts back from the greenhouses. To prevent shadows on the crop, trees located on the east, south, or west sides should be at a distance of 2.5 times their height.

A good site can make a difference in the functional and environmental operations of greenhouses.

1) Ground slope for drainage is an important factor. Adequate provision should be made to divert surface water away from the greenhouse.

2) A greenhouse needs a dependable source of energy in the form of electricity and /or other fuel for environmental control. An electric power distribution line adjacent to the site will reduce the investment on cable laying.

3) A short access to all weather public roads will facilitate material handling to and from greenhouse. Nearness to market is another added advantage.

4) A dependable supply of good quality of water is needed for a greenhouse.

5) Greenhouse should be located away from other buildings and trees to avoid obstruction of sunlight.

6) Orientation of the greenhouse is another important factor. An East-West oriented free standing greenhouse maintains better winter light as compare to a North-South oriented greenhouse. Therefore in north India a free standing greenhouse should be oriented in East-West direction. Gutter connected greenhouse be oriented North-South to avoid continuous shading of certain portions of the greenhouse due to structural members.

7) The greenhouse frame is the most important component of the greenhouse system. It provides support for glazing material and a place for fitting of environmental control equipment. Commonly used structural shapes are gable, quonset and gothic arch with minor changes to suit local conditions.

30.2 Standards for Construction

The Bureau of Indian Standards (BIS) has formulated the following standards with respect to greenhouse technology:

1) IS 14462: 1997- Recommendations for layout, design and construction of greenhouse structures.

2) IS 14485: 1998- Recommendations for heating, ventilating and cooling of greenhouse.

3) IS 15827: 2009- Plastic films for greenhouses – specifications.

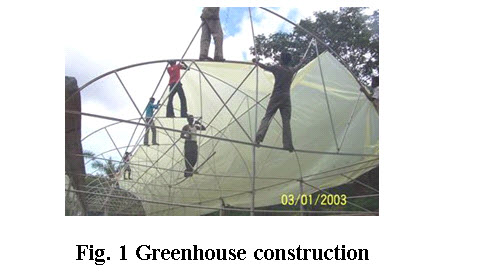

30.3 Methods of Construction

For locating the greenhouse, a piece of land larger than the grower’s immediate need should be acquired. The ultimate size of the greenhouse range should be estimated. Area should then be added to this estimated figure to accommodate service buildings, storage, access drives and a parking lot. The floor area of service buildings required for small farms is about 13% of the greenhouse floor area, and it decreases with the increase in size of the farm. On an average, service buildings occupy 10% of the growing area. The service building is centrally located in a nearly square design of the farm, which minimizes distance of movement of plants and materials. Doors between the service buildings and the greenhouse should be wide enough to facilitate full use of the corridor width. Doors at least 3.1 m wide and 2.7 m high are common. It is good to have the greenhouse gutter at least 3.7 m above the floor to accommodate automation and thermal blanket and still leave the room for future innovations.

Construction of Glass Greenhouses

Glass greenhouses have an advantage of greater interior light intensity over plastic panel and film plastic covered greenhouses. Glass greenhouses tend to have a higher air infiltration rate, which leads to lower interior humidity, which is advantageous for disease prevention. On the other hand, glass greenhouses have a higher initial cost than double-layer film plastic greenhouses. While comparing the price of a glass greenhouse to a film plastic greenhouse, one needs to take into account the initial purchase price of each as well as the cost of re-covering the film plastic greenhouse every three to four years.

Several types of glass greenhouses are designed to meet specific needs. A lean-to-type design is used when a greenhouse is placed against the side of an existing building. This design makes the best use of sunlight and minimizes the requirements for roof supports. It is found mostly in the retail industry. An even-span greenhouse is one in which the two roof slopes are of equal pitch and width. By comparison, a un-even-span greenhouse has roofs of unequal width, which makes the structure adaptable to the side of a hill. This style is seldom used today because such greenhouses are not adaptable to automation. The sidewall is eliminated between greenhouses, which results in a structure with a single large interior. Basically, three frame types are used in glass greenhouses, which are wood frames (6.1 m in width), pipe frames (12.2 m in width) and truss frames (15.2 m in width). Latest glass greenhouses are primarily of the truss frame type. Truss frame greenhouses are best suited for prefabrication. All-metal greenhouses proved cheaper to maintain since they required no painting. At present, virtually all glass greenhouse construction is of the metal type. The structural members of the glass greenhouse cast shadows that reduce plant growth during the dark months of the year. Aluminum sash bars are stronger than wooden ones; hence wider panels of glass can be used with aluminum bars. The reduction in materials and the reflectance of aluminum have given these metal greenhouses a great advantage over wooden greenhouses in terms of higher interior light intensity. Glass greenhouse construction of today can be categorized as high profile or low profile. The low profile greenhouse is most popular in the Netherlands and is known as the Venlo greenhouse. The low profile greenhouses uses single panels of glass extend from eave to ridge. The low profile greenhouse slightly reduces exposed surface area, thereby reducing the heating cost, but more expensive to cool. The high profile greenhouses require more than single panel to cover the eave to ridge. A problem with this design is the unsealed junction between pieces of glass in the inner layer. Moisture and dust may enter between the layers and reduce light transmission.

Construction of pipe framed greenhouses

Image source:

http://agritech.tnau.ac.in/horticulture/horti_Greenhouse%20cultivation.html

The choice of construction of pipe framed greenhouses often favours low initial investment and relatively long life. Galvanized mild steel pipe as a structural member in association with wide width UV- stabilized low density polyethylene (LDPE) film is a common option of greenhouse designers.

Material requirement

The structural members of greenhouse are

(a) Hoops

(b) Foundation

(c) Lateral supports

(d) Poly-grip assembly

(e) End frame

The materials requirement of (20m x 4.0m x 4.0m) floor area greenhouse is given:

i) GI pipe class ‘A’ (25 mm diameter, 85 cm long, 30 m total length)

ii) GI pipe class ‘B’ (15 mm diameter, 6.0 m long, 21 Nos.)

iii) GI sheet (20 gauges, size 90 x 24 cm, 4 sheets)

iv) MS flat (25x3 mm size, 4 m length)

v) Lateral support to end frames (10 mm diameter rod, 10 m length)

vi) Cement concrete (1: 3: 6 mix, 1.0 m3)

vii) UV- stabilized LDPE film (single layer 800 gauge, 5.4 m2/kg, 154 m2)

viii) Poly-grip ( channel 2000 x 3.5 x 4 cm, 2 Nos.; Angle 2000 x 2 x 2 cm, 2 Nos.; both made from the procured 20 gauge GI sheet, key 6 mm diameter, 56 mm length)

ix) Wooden end frames (5x5 cm wood, 0.15 m3)

x) Nuts and bolts 96 mm diameter, 35 mm long, 70 sets)

xi) Miscellaneous items like nails, hinges and latches as per requirement

Materials for Construction of Greenhouses

The following materials are commonly used to build frames of greenhouse

i) Wood

ii) Bamboo

iii) Steel

iv) Galvanized iron pipe

v) Aluminum and

vi) Reinforced Cement Concrete (RCC).

The selection of above materials was based on their specific physical properties, requirements of design strength, life expectancy and cost of construction materials.

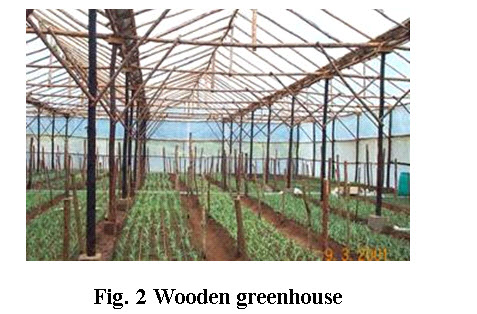

Wood

Image Source:

http://agritech.tnau.ac.in/horticulture/horti_Greenhouse%20cultivation.html

Wood and bamboo are generally used for low cost poly-houses. In low cost poly-houses, the wood is used for making frames consisting of side posts and columns, over which the polythene sheet is fixed. The commonly used woods are pine and casuarinas, which are strong and less expensive. In pipe-framed poly-houses, wooden battens can be used as end frames for fixing the covering material. In tropical areas, bamboo is often used to form the gable roof of a greenhouse structure. Wood must be painted with white colour paint to improve light conditions within the greenhouse. Care should be taken to select a paint that will prevent the growth of mold. Wood must be treated for protection against decay. Chromated copper arsenate and ammonical copper arsenate are water based preservatives that are applied to the wood that may come into contact with the soil. Red wood or cypress (natural decay resistance woods) can be used in desert or tropical regions, but they are expensive.

Galvanized iron (GI), aluminum, steel and reinforced cement concrete

GI pipes, tubular steel and angle iron are generally used for side posts, columns and purlins in greenhouse structure, as wood is becoming scarce and more expensive. In galvanizing operation, the surface of iron or steel is coated with a thin layer of zinc to protect it against corrosion. The commonly followed processes to protect against corrosion are: (i) Hot dip galvanizing (hot process) process: The cleaned member is dipped in molten zinc, which produces a skin of zinc alloy to the steel. (ii) Electro-galvanizing (cold process) process: The cleaned member is zinc plated similar to other forms of electro-plating. The galvanizing process makes the iron rust proof, to eliminate the problem of rusting of structural members. Aluminum and hot dipped GI are comparatively maintenance free. In tropical areas, double dipping of steel is required, as single dip galvanizing process does not give a complete cover of even thickness to the steel. Aluminum and steel must be protected by painting with bitumen tar, to protect these materials from corrosion, while these materials contact with the ground. Now-a-days, the greenhouse construction is of metal type, which is more permanent. RCC is generally limited to foundations and low walls. In permanent bigger greenhouses, floors and benches for growing the crops are made of concrete.

Glass

Glass has been traditional glazing material all over the world. Widely used glasses for greenhouse are: (i) Single drawn or float glass and (ii) Hammered and tempered glass. Single drawn or float glass has the uniform thickness of 3 to 4 mm. Hammered and tempered glass has a thickness of 4 mm. Single drawn glass is made in the traditional way by simply pulling the molten glass either by hand or by mechanical equipment. Float glass is made in modern way by allowing the molten glass to float on the molten tin. Coating with metal oxide with a low emissivity is used for saving energy with adequate light transmittance. Hammered glass is a cast glass with one face (exterior) smooth and the other one (interior) rough. It is designed to enhance light diffusion. This glass is not transparent, but translucent. Tempered glass is the glass, which is quickly cooled after manufacture, adopting a procedure similar to that used for steel. This kind of processing gives higher impact resistance to the glass, which is generally caused by hail. Glass used as a covering material of greenhouses, is expected to be subjected to rather severe wind loading, snow and hail loading conditions. The strength mainly depends on the length/width ratio of the panel and on the thickness of the panel, but the most widely used thickness is 4 mm.

Polyethylene film

Polyethylene is principally used today for two reasons - (i) Plastic film greenhouses with permanent metal frames cost less than glass greenhouses and (ii) plastic film greenhouses are popular because the cost of heating them is approximately 40% lower compared to single-layer glass or fiberglass-reinforced plastic greenhouses. The disadvantages are: these covering materials are short lived compared to glass and plastic panels. UV light from the sun causes the plastic to darken, thereby lowering transmission of light, also making it brittle, which leads to its breakage due to wind. A thermal screen is installed inside a glass greenhouse that will lower the heat requirement to approximately that of a double-layer plastic film greenhouse, but this increases the cost of the glass greenhouse. Polyethylene film was developed in the late 1930s in England and spread around the middle of this century. Commonly used plastic for greenhouse coverings are thermoplastics. Basic characteristics of thermoplastics are: (i) thermoplastics consists of long chain molecules, soften with heating and harden with cooling and this process is reversible and (ii) thermoplastics constitute a group of material that are attractive to the designer for two main reasons: (a) Thermoplastics have the following specific physical properties- stiffness, robustness and resilience to resist loads and deformations imposed during normal use and (b) It can readily be processed using efficient mass production techniques, result in low labor charge. The main reason to use polyethylene year round for greenhouse covering is due to presence of UV-inhibitor in it. Otherwise it lasts for only one heating season. UV-inhibited plastic cover may last for a period of 4 to 5 years. UV-grade polyethylene is available in widths up to 15.2 m in flat sheets and up to 7.6 m in tubes. Standard lengths include 30.5, 33.5, 45.7, 61 and 67 m. Some companies provide custom lengths up to a max. of 91.5 m. Condensation on polythene film is a big problem. Condensation causes disease development, development of water logged condition and oxygen deficient inside the greenhouse. Condensation reduces light intensity within the greenhouse. To avoid this problem, anti-fog surfactant, which discourages condensation, is built into the film or panel. Warm objects, such as plants, the greenhouse frame and soil radiate IR energy to colder bodies at night, which results in loss of heat in greenhouse. Since polyethylene is a poor barrier to radiant heat, it is formulated with IR-blocking chemicals into it during manufacture, will stop about half of the radiant heat loss. On cold and clear nights, as much as 25% of the total heat loss of a greenhouse can be prevented in this way and on cloudy nights only 15% is prevented. UV-stabilized polyethylene, on an average, transmits about 87% of photo-synthetically active radiation (PAR) into the greenhouse. IR absorbing polyethylene, reduces radiant heat loss, transmits about 82% of photo-synthetically active radiation (PAR) into the greenhouse. The amount of light passing through two layers of a greenhouse covering is approximately the square of the decimal fraction of the amount passing through one layer ( e.g. when 87% passes through one layer of UV-inhibited polyethylene, only 76% (0.87 x 0.87) passes through two layers. Similarly, when 82% passes through one layer of IR-absorbing polyethylene, only 67% (0.82 x 0.82) passes through two layers.

Polyvinyl chloride film (PVC films)

PVC films are UV light resistant vinyl films of 0.2 to 0.3 mm and are guaranteed for 4 to 5 years respectively. The cost of 0.3 mm vinyl film is three times that of 0.15 mm polyethylene. Vinyl film is produced in rolls upto 1.27 m wide. Vinyl films tend to hold a static electrical charge, which attracts and holds dust. This in turn reduces light transmittance unless the dust is washed off. Vinyl films are seldom used in the United States. In Japan, 95% of greenhouses are covered with plastic film, out of which 90% are covered with vinyl film.

Tefzel T2 film

The most recent addition of greenhouse film plastic covering is Tefzel T2 film (ethylene tetra-fluoro ethylene). Earlier, this film was used as covering on solar collectors. Anticipated life expectancy is 20 years. The light transmission is 95% and is greater than that of any other greenhouse covering material. A double layer has a light transmission of 90% (0.95 x 0.95). Tefzel T2 film is more transparent to IR radiation than other film plastics. Hence, less heat is trapped inside the greenhouse during hot weather. As a result, less cooling energy is required. Disadvantage is that, the film is available only in 1.27 m wide rolls. This requires clamping rails on the greenhouse for every 1.2 m. If reasonable width strips become available, the price is not a problem, because a double layer covering will still cost less than a polycarbonate panel covering with its aluminum extrusions, and will last longer, and will have much higher light intensity inside the greenhouse.

Polyvinyl chloride rigid-panel

Initially, PVC rigid panels showed much promise as an inexpensive covering material (almost 40% of cost of long lasting fiberglass reinforced plastics), has the life of 5 years. After commercial application, these panels indicated that the life expectancy was much shorter, less than 2 years. This is undesirable factor, because the cost of PVC panels was 4 to 5 times that of polyethylene film and they required much more time to install. Now-a-days, PVC rigid panels are not in use.

Fiberglass-reinforced plastic (FRP) rigid panel

FRP was more popular as a greenhouse covering material in the recent past. Advantage of FRP is that it is more resistant to breakage by factors, such as hail or vandals. Sunlight passing through FRP is scattered by the fibers in the panels, as a result the light intensity is rather uniform throughout the greenhouse in comparison with a glass covering. Disadvantages with these are the panels subjected to etching and pitting by dust abrasion and chemical pollution. Based on the grade, the usable life period of FRP panel varies. Some grades give 5 to 10 years, while better grades can last up to 20 years. FRP panels are flexible enough to conform to the shape of quonset greenhouses, which make FRP a very versatile covering material. FRP can be applied to the inexpensive frames of plastic film greenhouses or to the more elaborate frames of glass type greenhouses. The price of FRP greenhouse lies between that of a plastic film greenhouse and that of a glass greenhouse. But the cost is compensated by the elimination of the need for replacement of film plastic in every year or alternate years. Corrugated panels were used because of their greater strength. Flat panels are used occasionally for the end and side walls, where the load is not great. It is available in 1.3 m width, length up to 7.3 m and in a variety of colours. The total quantity of light transmitted through clear FRP is approximately equivalent to that transmitted through glass, but diminishes in relation its colour. For greenhouse crops in general, only clear FRP permits a satisfactory level of light transmission (88 to 90%). Coloured FRP has found a limited use in greenhouses intended for growing houseplants that require low light intensity and in display greenhouses for holding plants during the sales period. FRP has advantage over glass is that, it cools easily. FRP greenhouses require fewer structural members since sash bars are not needed.

Acrylic and polycarbonate rigid-panel

These panels have been available for about 15 years for greenhouse use. The panels have been used for glazing the side and end walls of plastic film greenhouses and retrofitting old glass greenhouse. Acrylic panels are highly inflammable, where as polycarbonate panels are non-flammable. Acrylic panels are popular due to their higher light transmission and longer life. Acrylic panels are available in thickness of 16 and 18 mm, and have 83% of PAR light transmission. Acrylic panels cannot be bent, but the thinner panels can be bent to fit curved-proof greenhouses. These panels are also available with a coating to prevent condensation drip. Polycarbonate panels are preferred for commercial greenhouses due to lower price, flame resistance and greater resistance to hail damage. Polycarbonate panels are available in thickness of 4, 6, 8, 10 and 16 mm. These panels are also available with a coating to prevent condensation drip and also with an acrylic coating for extra protection from UV light.

Procedure of erection

(1) A 4m by 20m rectangular area is marked on the site, preferably orienting the longer dimension in east-west direction. This rectangle will act as the floor plan of the greenhouse.

(2) Mark four points on the four corners of the rectangle.

(3) Start from one corner point and move along the length of marked rectangle, marking a point every 1.25 m distance until reaching the other corner (16 bays; 17 points). The same procedure is repeated on the other side of the rectangle.

(4) Dig 10 cm diameter holes upto 70 cm depth on all marked points with the help of bucket auger (or) a crowbar. This way a total of 34 holes on both the parallel sides of the greenhouse floor are obtained.

(5) Poly-grip sections formed according to the drawing into two 20m length.

(6) Fix the prefabricated poly-grip channels to the foundation pipes on 1.25 m spacing with the help of 6 mm diameter bolts.

(7) Set these assemblies on temporary supports between the holes with the foundation pipes hanging vertically in the holes.

(8) Pour cement concrete mix of 1: 3 : 6 around foundation pipes in such a way that the lower 15 cm to 20 cm ends are covered in concrete. The concrete is compacted around the foundation pipes with the help of the crowbar and is allowed to cure for 2-3 days.

(9) After curing, fill the soil around the foundation pipes to the ground level and compact it well.

(10) Position end frames on the two ends. Mark the position of legs and dug holes for fixing of legs. Now install both the end frames.

(11) Put the ringside of lateral support members on adjacent foundation pipe to the corner, and other side is hooked to the end frame.

(12) Put all the hoops in the foundation pipes in such a way that straight portion of hoop is inserted into the foundation and rests on the bolt used for fixing of poly-grip channel.

(13) Take a 20 m long ridge line by spacing 15 mm diameter pipes together. Put the 20m long pipe at the ridge line of the hoops.

(14) Use cross connectors on the ridge line pipe, in such a way that one half of it remains on the one side of the hoop and the other half on the other side.

(15) Put two bolts of 6 mm diameter in the holes provided in the ends of cross-connector. Tie a few of them with the help of nuts.

(16) Repeat the same procedure for joining all the hoops with ridge line pipe.

(17)While forming cross-connectors, the distance between the cross-connectors or hoops should be maintained 1.25 m center to center. This poly grip mechanism will provide a firm grip of the ridge line pipe and hoops at right angles without allowing for slippage.

(18) Spread polyethylene film over the structure from one end to the other end without wrinkles and keeping the edges together.

(19) Place polyethylene film between the poly-grip channel and right angle strip and secure them under pressure with the help of iron rods. The film is stretched gently and fixed on the other parallel side by poly-grip. This way the polyethylene is secured on both the longer sides.

(20) On the other two remaining ends, polyethylene is nailed to the end frames using wooden battens and nails.

(21) The remaining portion of the end frames is covered with polyethylene film, which is secured with wooden battens and nails.

(22) Mechanical ventilation, heating and cooling equipment is installed on the frames as per the crop requirement.

Reference:

-

www.ncpahindia.com/nmmi/Green_House.pdf

-

www.angrau.ac.in/media/10964/aeng252finallecturenotes.pdf

-

http://reporting.nmsu.edu/pubs/_circulars/circ556.html

-

http://agritech.tnau.ac.in/horticulture/horti_Greenhouse%20cultivation.html

Suggested readings:

-

Ghosh, A. (2009). Greenhouse Technology (The Future Concept of Horticulture). Kalyani Publishers, New Delhi.

-

Prasad, S. and Kumar, U. (2003). Greenhouse Management for Horticultural Crops. Agrobios (India), Jodhpur

-

Tiwari, G. N. (2003). Greenhouse Technology for Controlled Environment. Narosa Publishing House, New Delhi.