Site pages

Current course

Participants

General

Topic 1

Topic 2

Topic 3

Topic 4

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Topic 11

Topic 12

Topic 13

Topic 14

Topic 15

Lesson 13. Construction and working of Disc harrows, Spike-tooth and spring-tine harrows

Harrow:

Implement used for preparing fine seedbed

Helps in breaking the clods

Helps in pulverizing the soil or mixing soil thoroughly

Aerates soil and kills weeds

Used mostly in lighter soil conditions

Sometimes used to cover seeds after broadcasting

Harrow is a secondary tillage implement that cuts the soil to a shallow depth for smoothening and pulverizing the soil as well as cut the weeds and mix the material with the soil. Several types of harrow used are:

(1) Disc harrow

(2) Spring tooth harrow

(3) Spike tooth harrow

(4) Blade harrow (Bakhar)

(5) Guntaka

(6) Triangular harrow

(7) Bodela

(8) Zig-Zag harrow

(9) Bindha

(10) Other harrows.

Disc harrow

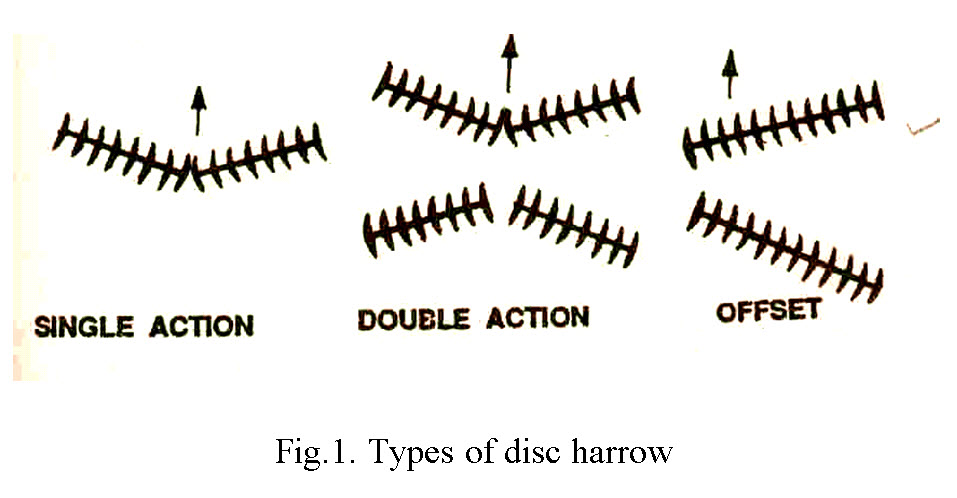

It is a harrow, which performs the harrowing operation by means of a set, or a number of sets of rotating discs, each set being mounted on a common shaft. Disc harrow is found very suitable for hard ground, full of stalks and grasses. It cuts the lumps of soil, clods and roots. Discs are mounted on one, two or more axles which may be set at a variable angle to the line of motion. As the harrow is pulled ahead, the discs rotate on the ground. Depending upon the disc arrangements, disc harrows are divided into two classes: a) Single action and b) Double action.

Single action disc harrow

It is a harrow with two gangs placed end to end, which throw the soil in opposite directions. The discs are arranged in such a way that right side gang throws the soil towards right and left side gang throws the soil towards left.

Double action disc harrow

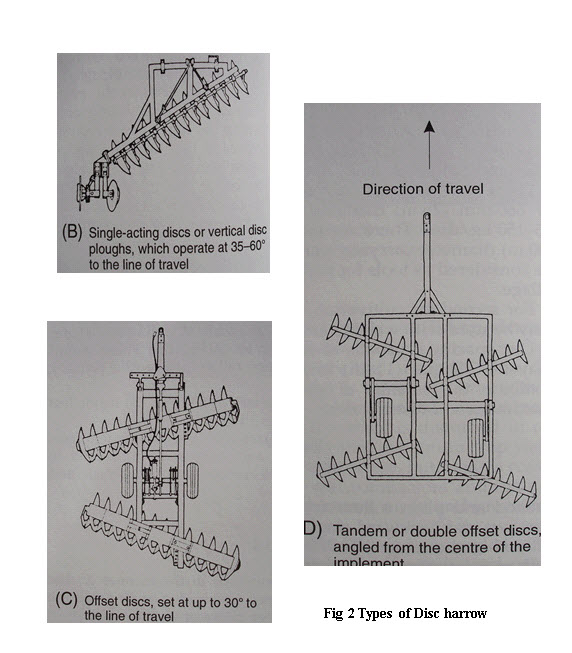

It is a disc harrow consisting of two or more gangs, in which a set of one or two gangs follow behind the set of the other one or two, arranged in such a way that the front and back gangs throw the soil in opposite directions and it generally covers the width ranging from 5 to 15 ft. Thus the entire field is worked twice in each trip. It may be of two types: a) Tandem and b) Off-set.

a) Tandem disc harrow

It is a disc harrow comprising of four gangs in which each gang can be angled in opposite direction (Fig.2).

b) Off-set disc harrow

It is a disc harrow with two gangs in tandem, capable of being off-set to either side of the centre line of pull. Two gangs are fitted one behind the other. The width covered by these types of harrows ranges from 4 to 30 ft. The soil is thrown in both directions because discs of

both gangs face in opposite directions. It is very useful for orchards and gardens. It travels left or right of the tractor. The line of pull is not in the middle, that is why it is called off-set disc harrow (Fig. 2). Off-set disc harrow is based on the basic principle that side thrust against the front gang is opposed by the side thrust of the rear gang. Hence the gangs are arranged at suitable angles so that both thrusts are counter balanced with each other.

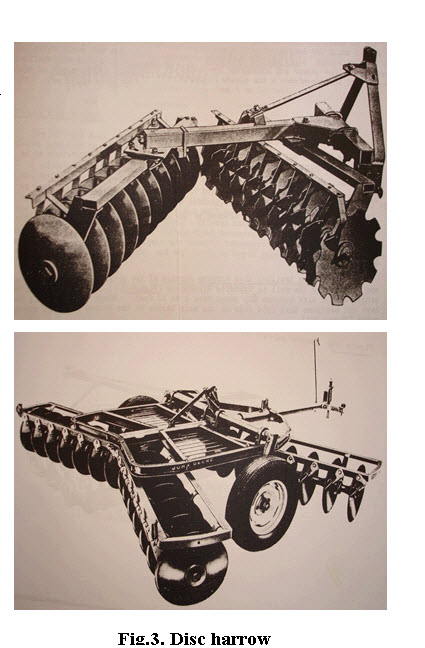

Disc harrows are of two types depending upon the source of power: tractor drawn and animal drawn. A disc harrow mainly consists of disc, gang, gang bolt, gang central lever, spool or arbor bolt or spacer, bearings, transport wheels, scraper and weight box (Fig.3).

i. Disc: It is a circular concave revolving steel plate used for cutting and inverting the soil. Disc is made of high glass heat-treated hardened steel. Tractor drawn disc harrows have concave discs of size varying from 35-70 cm diameter. Concavity of the disc affects penetration and pulverization of soil. Usually two types of discs are used in disc harrows, plain disc and cut away disc. Plain discs have plain edges and are used for all normal works. Most of the harrows are fitted with plain discs only. Cut away discs have serrated edges and cut stalks, grass and other vegetation.

ii. Gang: Each set of discs that are mounted on a common shaft is called the gang.

iii. Gang bolt or arbor bolt: It is a long heavy square headed bolt from the other end. A set of discs are mounted on the gang bolt. The spacing between the discs on the gang bolt ranges from 15 to 25 cm for light duty and 25 to 30 cm for heavy-duty harrows. The angle between the axis of the gang bolt and the direction of travel is called the gang angle.

iv. Gang control lever: A lever, which operates the gang mechanism of the disc harrow, is called the gang control lever.

v. Spool or spacer: The flanked tube, mounted on the gang bolt between every two discs to prevent the lateral movement of the disc on the shaft is called the `spool’ or `spacer’. It is just a device for keeping the discs at equal spacing on the gang bolt. The standard disk spacing is 7 inches.

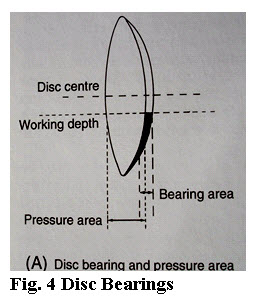

vi. Bearing: Bearing is essential to counter at the end thrust of the gang due to soil thrust. The harrow bearings are subjected to heavy radial and thrust loads. Chilled cast iron bearings are used to heavy radial and thrust loads and are also used due to their durability.

vii. Transport wheel: In trailing type disc harrow, the transport wheels are provided for transporting on roads and for preventing the edges of the discs from damage. Mounted type disc harrows do not require wheels for transportation.

viii. Scraper: It prevents disc from clogging. It removes the soil that may stick to the concave side of the disc.

ix. Weight box: A box like frame is provided on the main frame of the harrow for putting additional weight on the implement. Additional weight helps in increasing the penetration of the disc in the soil.

There are several factors which affect the penetration of disc harrow in the field.

The following are a few adjustments for obtaining higher penetration:

i. By increasing the disc angle

ii. By adding additional weight in harrow

iii. By lowering the hitch point

iv. By using the sharp edged discs of small diameter and losses concavity -----? Pl check

v. By regulating the optimum speed.