Site pages

Current course

Participants

General

Module 1. Role of mechanization and its relationsh...

Module 2. Performance and power analysis

Module 3. Cost analysis of machinery- fixed cost a...

Module 4. Selection of optimum machinery and repla...

Module 5. Break-even point and its analysis, relia...

Module 6. Mechanization planning

Module 7. Case studies and agricultural mechanizat...

Topic 8

Topic 9

Topic 10

Lesson 18. Development of computer programme for selection of farm equipment

A computer program can be developed, which can give results like required horse power of tractor, size of implement, own combine or not etc. for a particular farm situation. The user has to enter land holding, cropping pattern and soil type. The program cab be developed in FORTRAN, QBasic and C++ languages and is quite user friendly and flexible. The essential inputs to the program are

-

Cropping pattern

-

Area under crops

-

Soil type (light, medium, heavy)

After entering these inputs into the program, it will process these values with the help of some predefined parameters:

-

Tractor price in Rs/kW

-

Fixed cost of tractor in percentage

-

Price of crops in Rs/q

-

Crop yield in q/ha

-

Price of the implements in Rs/m

-

Timeliness cost factor

-

Labour charges in Rs/h

-

Land preparation operations

The parameters related to combine are

-

Combine rated power in kW

-

Specific fuel consumption in ml/kW/h

-

Fuel cost in Rs/l

-

Custom hiring rate in Rs/ha

When the inputs are given to the model the computer give out first the values of energy required and the width of implements in decimals. This is rough data for user. Thus after these values the computer selects the optimum size of tractor and its corresponding set of implements. These implements selected are within the range of width of implements selected by computer. The program also selects for the user that he opts for buying a combine harvester or custom hire it. This decision will be based upon the area under wheat and paddy.

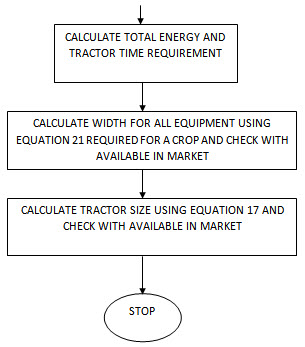

Using the computer program the optimum tractor power requirement and set of implements can be calculated for a particular farm. Optimum tractor power requirement for draw bar operation is function of area to be covered, soil type, energy required, number of operations of implements, labour cost and timeliness cost. Further the timeliness cost is dependent on the yield of crops, value of crops and timeliness cost factor of each crop. Optimum power required for transportation is a function of weight to be transported and distance to be travelled. After finding the optimum power required for all draw bar operations and for transportation, these are summed up by program to get total power requirement for a particular farm. Then the matching machinery to available tractor is calculated. The details of flow charts are given in Figs. 1 and 2.

Fig. 1: Flow chart for preparing computer programme for optimum selection of farm equipment.

Fig. 2: Flow chart for calculating tractor and farm equipment size.