Site pages

Current course

Participants

General

Module- 1 Scope and importance of food processing....

Module- 2 Processing of farm crops; cereals, pulse...

Module- 3 Processing of animal products

Module- 4 Principal of size reduction, grain shape...

Module- 5 Theory of mixing, types of mixtures for ...

Module- 6 Theory of separation, size and un sized ...

Module- 7 Theory of filtration, study of different...

Module- 8 Scope & importance of material handl...

Lesson 16. Size Reduction Equipments

16.1 Size Reduction Equipments

There is a very wide range of size reduction equipment available and the following passages describe briefly the essential details of only a few of the most important types.

(a) Hammer Mill: A standard hammer mill is shown in (Fig. 15.1a) and consists of a series of hinged or fixed hammers attached to a shaft which rotates at high speed; peripheral speeds up to 100 m/s are possible. The hammer mill employs impaction primarily, although attrition also takes place. The solids to be milled are impacted in the small gap between the hammer and a toughened breaker plate on the inside casing of the mill. Consequently such devices are used primarily for hard and brittle materials such as pepper, sugar, dried milk, dried vegetables and spices, but hammer mills also find applications with fibrous and vegetable matter.

Types of mill (a) hammer (b) roller (c) disc_module_4_lesson_15

(b) Crushing rolls:

These employ a compression mechanism and are often used in intermediate crushing stages. The rolls are approximately 0.6 m in diameter, rotate up to 300 rpm and are designed to nip large lumps of material. Smooth rolls are employed for producing flaked materials such as corn and for semi-liquids such as chocolate. However, the surface may be corrugated for coarse grinding of seeds and grain. A series of rollers may be employed (Fig. 15.1b) with increasingly smaller gaps between the rollers, and greater pressure exerted, to give progressively finer and finer grinding.

(c) Disc mills:

Disc mills (Fig. 15.1c) utilise either a rotating disc which grinds material between itself and a stationary plate or two counter-rotating discs and employ largely attrition. The pin mill is a variation on this geometry in which the discs have pins or teeth and material is fed axially and moves radially outwards. The mechanism employed now is impaction at very high peripheral velocities up to 160 m/s. Disc mills have found application to sugar, nuts, cocoa, nutmeg, cereals and rice.

(d) Tumbling Mills:

The ball mill consists of a horizontal rotating drum (with differing sizes of freely moving metal or ceramic balls, about 25–150 mm in diameter, impacting the material to be crushed. Ball mills are used for fine grinding. In the rod mill balls are replaced with rods equal in length to the drum. Attrition occurs in addition to impaction. Rod mills overcome the problem of ball mills clogging with sticky material.

15.2 Operating methods

Batch operation is limited to devices such as the ball mill; most other milling equipment is used

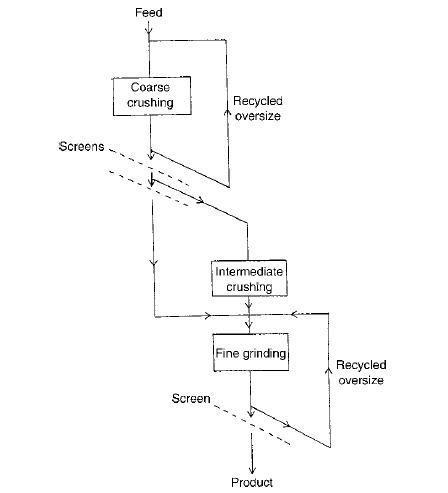

Fig. 15.2 Closed circuit grinding continuously.

However, an important distinction must be made between open circuit and closed circuit milling. In open circuit crushing the material passes through the mill once, with no rework of any oversize material, and results in a wide particle size distribution. The largest particles in the output stream must be made to be smaller than the upper limit for the product.

This is wasteful of energy and gives too many fines. Closed circuit grinding (Fig. 15.2) includes a classification step to remove the undersize particles as product and then recycle the oversize back to the mill. The operation, although requiring a greater investment, is much more efficient and gives a more homogeneous product.

15.3Fineness modulus

To characterize the overall fineness or coarseness of an aggregate sample, a concept of Fineness modulus is developed. Fineness Modulus is an index that indicates the uniformity of grind in the resultant product.

Fineness modulus is an empirical factor obtained by adding the percentage cumulative weight fraction of material retained on each of a specified series of standard sieves, and dividing the sum by 100.

Although the fineness modulus gives an average particle size, it does not indicate the distribution of fines and coarses in any sample and the average grain size is not proportional to the modulus index. This can be overcome by using uniformity index which indicates the distribution of fines and coarses in the resultant sample that is indicates the relative proportions of fines, medium and coarse material. Thus recommended procedure is to quote both the indices. The same value of fineness modulus may be obtained from several different particle-size distributions. In general a small value indicated a fine material while a large value indicates a coarse material. The value for fine aggregates commonly ranges from 2.00 to 4.00 and for coarse aggregate from 6.50 to 8.00 when all the material is finer than the 1-1/2-in. (38.1-mm) sieve. Combinations of fine and coarse aggregates have intermediate values.

For food grain flour analysis, a set of IS sieves No. 100, 70, 50, 40, 30, 20, and 15- mesh with a pan and cover are used. The standard procedure specifies a 250 g sample oven dried to constant weight at 105oC is placed and shaken in the RoTap sieve shaker for 5 min.

15.4 Steps in particle size analysis

The particle size of ground grain performs a critical role in determining feed digestibility, mixing performance, and pelleting. Therefore, periodic particle size evaluation is a necessary component of a feed manufacturing quality assurance program. The equipment required for particle size analysis includes a scale, shaker, sieves, sieve cleaners, and brushes. A scale that is accurate to ±0.1 grams is required (ASAE, 1993). The recommended sieve shaker is a Tyler RoTap (Mentor, OH). The RoTap mechanically reproduces the circular motion that occurs during hand sieving, while at the same time tapping the sieve stack to help the particles fall through the mesh screens. It is designed to hold a maximum of six full-height (13 half height), 8-inch diameter sieves and a pan (Tyler, 1976). Sieves vary in diameter and height and may be constructed of brass or stainless steel. It also is important that sieves be properly cleaned during weighing. Literature from Tyler (1976) recommends that a soft brass wire brush be used to clean sieves coarser than 100 mesh (IS Sieve No. 100) anda nylon bristle brush for sieves finer than 100 mesh. The authors have found that a circular vacuum attachment brush also works well for the finer sieves. Exerting too much pressure should be avoided because it will cause the screens to sag, and their accuracy will decrease. Tapping the sides of the sieve can be used to dislodge particles. It also may be necessary to wash the sieves to remove particles that cannot be removed with a brush. Sieves should be washed in a warm, soapy water.

A representative sample of 250g is taken first. After the sample has been obtained, the following steps are required:

arrange the sieve stack so the coarsest is on top and the finest on bottom (as the Indian Standard Sieves number decreases, the opening becomes smaller)

-

put the sample on the top sieve and place sieve stack on the shaker

-

allow shaker to run for 10 minutes

-

remove the sieves stack from shaker

-

gently tap the sides of each sieve with the brush before removing from the stack

-

place the sieve with the retained material on the scale

-

tare the scale (if using a triple beam balance, weigh the sieve and retained material together)

-

remove and thoroughly clean the sieve

-

weigh back the empty sieve and record the weight; the weight should be negative, but only the value needs to be recorded (if you are using a triple beam balance, subtract the difference between the sieve with and without material)

-

enter the weight values in the appropriate columns of the table

A simple method for determining the fineness modulus is shown in the tabulated example.

|

IS series (Sieves No) |

Sieve sizes (in mm) |

Weight of material retained (g) |

Cumulative wt. Of material retained (g) |

% cumulative weight fraction of material retained |

|

100 |

1.000 |

0.0 |

0.0 |

0.0 |

|

70 |

0.708 |

9.8 |

9.8 |

3.92 |

|

50 |

0.500 |

16.7 |

26.5 |

10.6 |

|

40 |

0.420 |

35.4 |

61.9 |

24.76 |

|

30 |

0.296 |

83.2 |

145.1 |

58.04 |

|

20 |

0.211 |

96.6 |

241.7 |

96.68 |

|

15 |

0.157 |

8.3 |

250 |

100 |

|

Pan |

- |

0.0 |

250 |

100 |

Fineness modulus =\[{{\sum {\% \,cumulative\,weight\,fraction\,of\,material\,retained\,above\,each\,sieve} } \over {100}}\]

D (in mm) = 0.135 (1.366) FM ...............................(15.1)

Worked Example 15.1

A typical example of calculation of fineness modulus using percentage passing is shown below:

|

Sieve Size (IS series) |

Total Percent retained |

||

|

Fine aggregate |

Coarse aggregate |

Combined Coarse & Fine 65:35 |

|

|

100 |

0 |

91 |

59 |

|

70 |

4 |

100 |

66 |

|

50 |

21 |

100 |

72 |

|

40 |

46 |

100 |

81 |

|

30 |

74 |

100 |

91 |

|

20 |

89 |

100 |

96 |

|

15 |

95 |

100 |

98 |

|

Total |

329 |

691 |

563 |

|

Fineness Modulus |

=3.29 |

6.91 |

5.63 |

Many specified grading, are expressed as percentages passing a specified series of sieves. To avoid having to make numerous calculations to change these grading from percentages passing to percentages retained in order to calculate fineness modulus, the following procedure can be used to calculate fineness modulus using percentages passing. The example is for the same grading as in Example 4.1 but when they are expressed as percentages passing.

|

Sieve Size (IS series) |

Total Percent passing |

||

|

Fine aggregate |

Coarse aggregate |

Combined Coarse & Fine 65:35 |

|

|

100 |

100 |

9 |

41 |

|

70 |

96 |

0 |

34 |

|

50 |

79 |

0 |

28 |

|

40 |

54 |

0 |

19 |

|

30 |

26 |

0 |

9 |

|

20 |

11 |

0 |

4 |

|

15 |

5 |

0 |

2 |

|

Total |

371 |

9 |

137 |

For this procedure

Fineness modulus =\[\left( {{{N(100) - sum\,total\,of\,percent\,passng} \over {100}}} \right)\]

Where N= number of sieves involved

Then for fine aggregates,

Fineness modulus =\[{{7(100) - 371} \over {100}}\]=3.29

For Coarse aggregates:

Fineness modulus =\[{{7(100) - 9} \over {100}\]=6.91

And for Combined Coarse & Fine 65:35

Fineness modulus =\[{{7(100) - 137} \over {100}}\]=5.63

References

1. Henderson, S. M. and Perry, R. L. (1955) Agricultural Process Engineering. John Wiley, New York.

2. ASAE, 1993. Method of determining and expressing fineness of feed materials by sieving. ASAE Standard ASAE S319.2.

3. Smith, P. G. (2011) Introduction to Food Process Engineering. Springer, London.

4. Barbaso-Canovas, G. V., Ortega- Rivas, E., Juliano, P., Yan, H. (2005) Food Powders: Physical Properties, Processing, and Functionality. Kluwer Academic, New York.