Module 5. Air cycles

Lesson 11

DUAL COMBUSTION CYCLE, NUMERICAL PROBLEMS

11.1 Dual Combustion Cycle

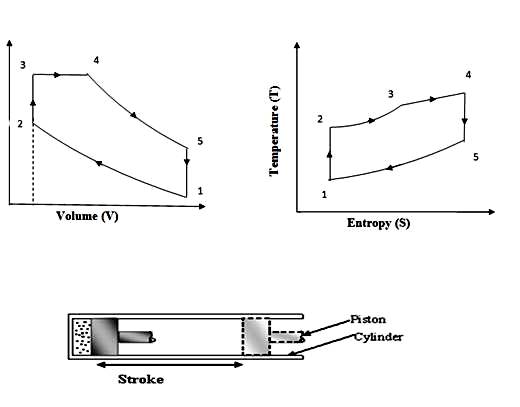

Dual combustion cycle is a combination of ‘Otto’ cycle and ‘Diesel cycle’. Here the heat absorption process takes place both at constant volume and constant pressure as shown in fig 11.1. Modern high speed diesel engines work on this cycle. We have already come to know that constant volume heat absorption is more efficient than at constant pressure. The constant volume heat absorption or combustion may be somewhat used by advancing the diesel injection i.e., doing it before the end of compression stroke but this is limited by high pressure generated, at the end of combustion or heat absorption process. So limiting the high pressure generated, dual combustion cycle is used in which combustion take place both at constant volume and constant pressure as shown in fig 11.1. The thermal efficiency or air-standard efficiency of a dual combustion cycle lies between those of ‘Otto’ cycle and ‘Diesel Cycle’.

The thermal efficiency of a dual combustion cycle can be calculated by following mathematical analysis:

Consider one kg of air in a closed system of cylinder piston arrangement. This air undergoes the various processes of heat addition, rejection, expansion and compression etc as shown in the diagram of cycle in fig 11.1

Considering the process 2-3 of initial heat addition at constant volume and process 3-4 of final heat addition at constant process,

Total heat absorbed by air = CV (T3−T2) + CP (T4−T3) ……… (i)

Considering the process 5-1 of heat rejection at constant volume like in ‘Otto’ and Diesel cycle

Heat Rejected = CV (T5−T1) ……… (ii)

Fig. 11.1(a) Dual Combustion Cycle on P-V Chart Fig.11.1(b) Dual Combustion Cycle on T-S Chart

The other two process of expansion and compression of air in between are reversible adiabatic in the same way as in Otto and Diesel Cycles.

Thus naturally the net work done per cycle as per first law of thermodynamics will be

Net work = Heat Absorbed−Heat Rejected

We know that thermal efficiency of air cycle is given as

![]()

![]()

![]()

![]() ………

(iii)

………

(iii)

From the adiabatic compression process 1-2

![]()

Or

T2

= ![]()

From the constant volume heat addition process 2-3

![]()

or

![]()

=![]()

![]()

From the

constant pressure heat addition process 3-4![]()

![]()

or

![]()

= ![]()

From the adiabatic expansion process 4-5

![]()

or

![]()

![]()

![]()

Putting the value of temperatures T2, T3, T4 and T5 in terms of temperature T1 in the equation (iii)

![]()

![]()

Or

![]() ……… (Eq.

11.1)

……… (Eq.

11.1)

It can be judged from equation11.1 that the value of pressure ratio, α is always greater than 1. So for a given volume of ρ and γ, the efficiency increases than that of Diesel cycle but still it is less than that of Otto cycle.

Hence the thermal efficiency of a dual combustion cycle is in between that of Otto cycle and Diesel cycle.

If ρ=1 is substituted in equation 11.1, it becomes efficiency of an ‘Otto’ cycle.

If α=1

is substituted in equation 11.1, it becomes efficiency of a Diesel cycle.

11.2 Numerical Problems

11.2.1 In a standard OTTO cycle, the compression ratio is 7 and the compression begins at 1 bar and 313°K. The heat added is 2510 kJ/kg. Find

(1) Maximum pressure and temperature of cycle;

(2) Work done per kg of air

(3) Cycle efficiency

(4) Mean effective pressure

Solution

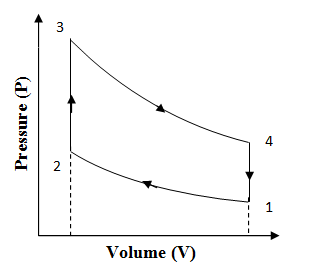

Fig. 11.2

Considering Process 1-2

![]()

=

![]()

=

681.7 K![]()

![]()

or P2 = P1 rγ = 1× (7)1.4 = 15.25 bar

Considering the process 2-3

Heat Added, Qh = CV (T3−T2) = 2510 (Given)

or 0.714 (T3−681.7) = 2510

or T3 = 4197 K (Ans)

For constant volume, process

![]()

or

![]()

Considering process 3-4

![]()

or ![]()

![]()

Heat Rejected = CV (T4−T1)

= 0.174(1927−313)

= 1152 kJ

∴ Work done = Heat Supplied−Heat Rejected

= 2510−1152 = 1358 kJ (Ans)

Cycle efficiency:

![]()

= 0.54 or 54% (Ans)

Mean effective Pressure:

P1V1 = m R T1

Or ![]()

= 0.899 or 0.9 m3

![]()

![]()

11.2.2 A diesel engine working on theoretical Diesel cycle has a diameter of 20 cm and stroke 20 cm. The clearance volume is 10% of the swept volume. Determine the compression ratio and air standard efficiency of the engine, if the cut-off takes place at 8 per cent of the stroke.

Solution

Stroke volume can be calculated from the given dimension of engine as

![]()

![]()

= 6.283×10-3 m3

Clearance volume VC = 0.1×VS (Given)

= 0.1×6.283×10-3

= 6.283×10-4 m3

So, total volume V1 = VC + VS

= 6.912×10-3 m3

Compression ratio is given as

![]()

= 11 (Ans)

Cut-off Ratio,

![]()

![]()

= 1.8

The air standard efficiency of the cycle is given as:

![]()

![]()

= 0.563 or 56.3% (Ans)