Module 7. Performance of I.C. engine

Lesson 18

NUMERICAL PROBLEMS

18.1 Numerical Problems

18.1.1 Following observations were recorded during a test on a single cylinder 4- stroke oil engine

Bore =300mm; Stroke = 450mm; Speed =300rpm; imep = 6bar; Net brake load = 1.5 kN; Brake drum diameter = 1.8m; Brake rope diameter = 2 cm.

Calculate: (i) Indicated Power

(ii) Brake Power

(iii) Mechanical Efficiency

Solution

![]()

![]() (Ans)

(Ans)

![]()

(Ans)

![]()

![]()

18.1.2 The following data refers to a petrol engine working on OTTO four stroke cycle.

Brake Power = 14.7 kW

Suction Pressure = 0.9 bar

Mech. Efficiency = 80%

Compression Ratio = 5

Index of Compression curve = 1.35

Index of expansion curve = 1.3

Maximum Explosion pressure = 24 bar

Engine Speed = 1000 r.p.m

Ratio of stroke to bore = 1.5

Find the diameter and stroke of piston.

Solution

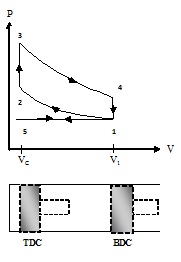

Fig. 18.1 ‘OTTO-Four stroke cycle’

Considering compression process 1-2

![]()

Or ![]()

Considering expansion process 3-4

![]()

![]()

Now work done per cycle by engine

= Work done by engine during expansion process- Work done on engine during compression process

=Area 1-2-3-4

![]()

![]()

![]()

Putting V4 = 5V3 (As Compression radio, r = 5)

Net work done/cycle = 20.98 × 105V3 Nm

Therefore, mean effective pressure

![]()

![]()

![]()

![]()

Now,![]()

Also,![]()

![]()

= 18.37 kW

![]()

Or D3 = 0.003567

Or D = 0.1527 m (Ans)

Or 152.7 mm

L = 1.5D = 229.2mm (Ans)

18.1.3 A four cylinder two stroke cycle petrol engine develops 30 KW at 2500rpm. The mean effective pressure on each piston is 8 bars and mechanical efficiency is 80%. Calculate the diameter and stroke of each cylinder with stroke bore ratio 1.5. Also calculate the fuel consumption of the engine, if brake thermal efficiency is 28%. The calorific value of fuel is 43900 kJ/ kg.

Sol:

![]()

![]()

Also![]()

Or

![]()

Or D = .062 m or 62 mm (Ans)

![]()

(ii) Fuel Consumption:

![]()

![]()

![]()

18.1.4 Following data refers to a four-stroke, four cylinder petrol engine:

Fuel Used = 19.2 kg/hour

Fuel to Air Ratio = 1:16 by weight

Suction Pressure = 1bar

Suction Temperature = 30oC

Stroke to bore ratio = 1.25

Engine RPM = 2400

Volumetric Efficiency = 78%

Find the stroke and bore of engine cylinders.

Sol: Mass of air supplied per hour = 16 × Mass of fuel supplied per hour

= 16 × 19.2

= 307.2 kg/hour

Mass of air supplied

per

second

![]()

Mass of air fuel mixture

![]()

Assuming air fuel

mixture as pure air for calculating its volume

![]()

![]()

= 0.0788 m3/s

Theoretical volume of air fuel mixture sucked by engine

![]()

![]() ………

(i)

………

(i)

This theoretical volume sucked

should be equal to stroke volume of the engine i.e.

![]()

![]()

![]()

=

157 D3 ………

(ii)

From (i) & (ii) 157 D3 = 0.101

![]()

=

0.86 m = 86mm (Ans)

![]()

18.1.5 A 4- cylinder, 4-stroke petrol engine having 90 mm bore and 130mm stroke develops 30 kW of power while running at 1500 r.p.m and using a 20% rich mixture. The theoretical air-fuel ratio is 15:1. Calorific value of petrol is 46000 kJ/ kg. Volumetric efficiency measured at 15oC and 760 mm of mercury as standard temperature and pressure is 70% and mechanical efficiency is 90%.

Find:

(i) Indicated Thermal efficiency

(ii) Brake mean effective pressure

(iii) Brake Thermal efficiency

Sol:

Total swept volume of the engine

![]()

![]()

![]() Volume

of air drawn in the engine in the suction stroke

Volume

of air drawn in the engine in the suction stroke

![]()

![]()

![]()

Volume flow rate of the 4-stroke engine

![]()

![]()

= 1.737 m3/min

This volume flow rate is at pressure 760 mm of mercury (1.013 bar) and temperature 15o C (298K).

So mass flow rate of air

![]()

= 2.057 kg/min

Mass flow rate

of fuel used = ![]()

![]()

Using 20% rich mixture actual mass flow rate of fuel used

![]()

= 0.164 kg/min

![]()

Given that, Brake power, B.P = 30 kW

![]()

![]()

![]()

(a) Indicated Thermal Efficiency

![]()

= 0.264 or 26.4% (Ans)

(b)

Brake

thermal efficiency

![]()

(Ans)

(c) Brake mean Effective Pressure

![]()

![]()

![]()

![]()

18.2 Unsolved Problems

18.2.1 A 4-cylinder petrol engine works on a mean effective pressure of 5 bar and engine speed of 1250 r.p.m. Find the indicated power developed by the engine if the bore is 100 mm, and stroke 150 mm.

[Ans. 6.11 kW]

18.2.2 A 4-cylinder, four stroke diesel engine runs at 1000 r.p.m. The bore and stroke of each cylinder are 100 mm and 160 mm respectively. The cut off is 6.62% of the stroke. Assuming that the initial condition of air inside the cylinder is 1 bar and 200 C, mechanical efficiency of 75% ; Calculate the air-standard efficiency and brake power developed by the engine.

Also, calculate the brake specific fuel consumption if the air/fuel ratio is 20: 1. Take R for air as 0.287 kJ/kg K and clearance volume as 0.000084 m3.

[Ans. 61.4%, 21.75kW, 0.4396 kg/kW]

18.2.3 A four stroke gas engine develops 4.2 kW at 180 r.p.m. and at full load. Assuming the following data, calculate the relative efficiency based on indicated power and air-fuel ratio used. Volumetric efficiency= 87 %, mechanical efficiency =74%, clearance volume = 2100 cm3, swept volume = 9000 cm3, fuel consumption = 5 m3/h, calorific value of fuel = 16750 kJ/m3.

[Ans. 50.2%, 7.456:1]

18.2.4 The following observations were recorded during a trial of a four stroke engine with rope brake dynamometer:

Engine speed = 650 r.p.m., diameter of brake drum = 600 mm, diameter of rope = 50 mm, dead load on the brake drum = 32 kg, spring balance reading = 4.75 kg.

Calculate the brake power.

[Ans. 5.9 kW]

18.2.5 During a 60 minutes trial of a single cylinder four stroke engine the following observations were recorded:

Bore = 0.3 m, stroke = 0.45 m, fuel consumption = 11.4 kg, calorific value of fuel = 42000 kJ/kg, brake mean effective pressure = 6.0 bar, net load on brakes = 1500 N, r.p.m. = 300, brake drum diameter = 1.8 m, brake rope diameter = 20 mm, quantity of jacket cooling water 600 kg, temperature rise of jacket water =550C, quantity of air as measured = 250 kg, exhaust gas temperature = 4200C, cp for exhaust gases = 1 kJ/kg K, ambient temperature = 200C.

Calculate: (i) Indicated power; (ii) Brake power;

(iii) Mechanical efficiency (iv) Indicated thermal efficiency.

Draw up a heat balance sheet on minute basis.

[Ans. (i) 47.7 kW; (ii) 42.9 kW; (iii) 89.9%, (iv) 35.86%]

18.2.6 A two-cylinder four stroke gas engine has a bore of 380 mm and a stroke of 585 mm. At 240 r.p.m. the torque developed is 5.16 kN-m.

Calculate: (i) Brake power

(ii) Mean piston speed in m/s

(iii) Brake mean- effective pressure.

[Ans. (i) 129.8 kW; (ii) 4.68 m/s; (iii) 4.89 bar]

18.2.7 A 4-cylinder, four-stroke diesel engine has a bore of 212 mm and a stroke of 292 mm. At full load at 720 r.p.m., the b.m.e.p. is 5.93 bars and the specific fuel consumption is 0.226 kg/kWh. The air/fuel ratio as determined by exhaust gas analysis is 25: 1. Calculate the brake thermal efficiency and volumetric efficiency of the engine.

Atmospheric conditions are 1.01 bar and 150C and calorific value for the fuel may be taken as 44200 kJ/kg.

[Ans. 36%; 76.5%]

18.2.8 During the trial (60 minutes) on a single cylinder oil engine having cylinder diameter 300 mm, stroke 450 mm and working on the four stroke cycle, the following observations were made :

Total fuel used = 9.6 liters, calorific value of fuel = 45000 kJ/kg, total number of revolutions = 12624, gross indicated mean effective pressure = 7.24 bar, pumping i.m.e.p. = 0.34 bar, net load on the brake = 3150 N, diameter of brake wheel drum = 1.78 m, diameter of rope = 40 mm, cooling water circulated = 545 liters, cooling water temperature rise = 250 C, specific gravity of oil = 0.8.

Determine: (i) Indicated power. (ii) Brake power. (iii) Mechanical efficiency.

Draw up the heat balance sheet on minute basis.

[Ans.

(i) 77 kW; (ii) 61.77 kW; (iii) 80.22%]