Module 12. Boiler draught

Lesson 29

NATURAL DRAUGHT

29.1 Determination of the Height of Chimney for a Given Value of Natural Draught

For determination of the height of chimney required to produce certain amount of natural draught, we have to determine the density of flue gases inside the chimney, ρg and that of cold air outside the chimney ρa.

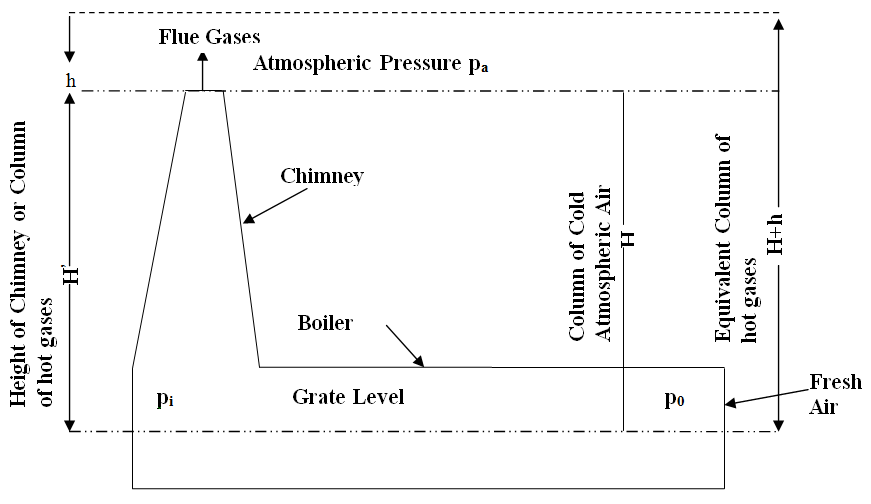

A shown in fig 29.1, if ‘H’ is the height of chimney and Pa is the atmospheric pressure at the top level of the chimney then

Fig. 29.1 Natural draught system

The absolute total pressure at grate level inside the chimney is given as

![]()

And total pressure at grate level outside the chimney

![]()

Then

draught produced, given by its definition will be equal to

![]() N/m2

(Pa)

.........

(Eq. 29.1)

N/m2

(Pa)

.........

(Eq. 29.1)

Where,

ρa

and ρg are in kg/m3

g = acceleration due to gravity = 9.81 m/sec2

H = Height of chimney in ‘m’

Calculation of ρa and

ρg

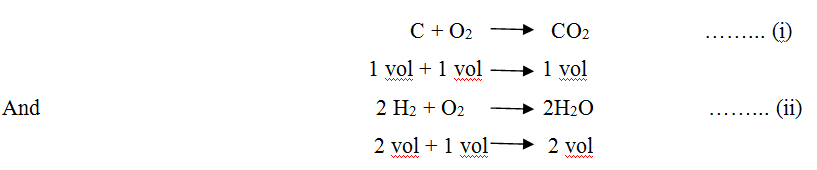

We know the combustion chemistry of carbon and hydrogen

From equation (i) & (ii) it is clear that volume of O2 supplied for combustion of a unit quantity of carbon is equal to volume of CO2 produced at same pressure and temperature and volume of O2 supplied for combustion of hydrogen is half of volume of steam produced at same temperature and pressure and volume of N2 supplied remains same at same temperature and pressure, as it does not take part in combustion.

Now, the hydrogen content in the fuel is very less because of which only, the volume of combustion product increases. So, it can be neglected and it is safely assumed that volume of products of combustion will be equal to volume of air supplied when both reduced to same temperature and pressure conditions.

Let m = mass of air required per kg of fuel burnt

Then mass of chimney gases = (m+1) kg per kg of fuel burnt

Let T = mean absolute temperature of chimney gases in K

T1= Absolute temperature of outside air in K

![]()

![]() .........

[Sub Eq. (i)]

.........

[Sub Eq. (i)]

Where, P is in N/m2, T in oK and Ra in J/kg K

And volume of (m+1) kg of flue gases

will also be same at temperature T1 i.e. ![]()

But hot flue gases are at

temperature T. So their volume at temperature T will be:

![]() (Considering

atmospheric Pressure Pa, Constant)

(Considering

atmospheric Pressure Pa, Constant)

![]()

![]()

![]() Density

of inside flue gases

Density

of inside flue gases

![]() .........

[Sub Eq. (ii)]

.........

[Sub Eq. (ii)]

Here pressure P is in N/m2, Ra in J/kg K and temperature in K

Putting

the value of density of fresh air at temperature T1 and of hot flue

gases at temperature T2 in equation 29.1

![]()

![]()

![]() .........

(Eq. 29.2)

.........

(Eq. 29.2)

Putting

the values of

Atmospheric

Pressure P = 101300 Pa (N/m2)

Ra

= Characteristic gas constant for air = 287 J/ kg K

and

g = Acceleration due to

gravity = 9.81 m/sec2

Draught Produced

![]()

![]() .........

(Eq. 29.3)

.........

(Eq. 29.3)

By this formula the theoretical height of chimney required may be determined for producing a certain amount of natural draught, if we know the absolute temperature of flue gases inside the chimney and of air outside the chimney and mass flow rate of air per kg of fuel burnt.

Actual Draught produced by chimney is generally less than 12 mm of water.

From equation 29.2, it may be seen that the draught produced by the chimney becomes more effective with increase in height of chimney and temperature of flue gases.

29.2 Determination of Diameter of Chimney

Let us find out the draught produced in terms of height of flue gases i.e. h meters.

So,

it will be expressed as pd = ρg. g. h

And From Equation 29.2

![]()

![]()

![]()

Putting the values of ρg from sub eqn (ii)

![]()

![]()

Now

assuming that draught losses are Nil and all the draught contribute to

imparting velocity to flue gases, velocity of flue gases can be given by:

![]()

If we take into account the

frictional pressure losses in chimney and let it be hf,

then

![]() .........

(Eq. 29.4)

.........

(Eq. 29.4)

![]()

Where k is a constant the value of which is given as

k= 0.825 for brick chimney, 1.1 for steel chimney

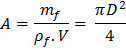

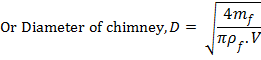

Also, the mass of flue gases flowing through any section of chimney will be given by

![]()

Or

![]() .........

(Eq. 29.5)

.........

(Eq. 29.5)

In this way, the height and diameter of chimney to produce a given natural draught can be estimated theoretically.

29.3 Efficiency of Chimney

From equation 29.3, it is clear that for a given height of chimney draught depends on temperature of hot gases leaving the chimney. Natural Draught is directly proportional to outlet temperature of flue gases. It increases with the increase in outlet temperature. But high temperature of hot gases leaving chimney means the loss of heat energy and hence thermal efficiency of boiler. Thus natural draught is created at the cost of thermal efficiency.

However in artificial draught system, the flue gases can be made to leave the chimney at a reduced temperature, thus increasing the thermal efficiency or we can say that more heat of flue gases can be harnessed and given to steam. Thus the efficiency of chimney can be calculated on this basis:

Let T = Temperature of flue gases in natural draught

T2 = Temperature of flue gases in artificial draught

Cp = mean sp heat of flue gases in J/kg K

Then extra heat carried away by flue gases due to higher temperature required for producing natural draught = Cp (T – T2) for one kg of flue gases.

Draught Produced in terms of height

of column of exhaust

gases

![]()

It can give

maximum energy to one kg of flue gases = m. g. h ![]()

Thus efficiency of chimney can be

calculated as

![]() .........

(Eq. 29.6)

.........

(Eq. 29.6)

It is to be noted that even for a very tall chimney, the efficiency, will be

less than 1%. So it is a very inefficient mean to create draught. Due to this

reason for and for demand of energy efficiency, natural drought is not used in

most of the commercial boilers.