Module 10 . Pumps

Lesson 29

CLASSIFICATION OF PUMPS

29.1 Introduction

Pumps are used to transfer and distribute liquids in various industries. Pumps convert mechanical energy into hydraulic energy. Electrical energy is generally used to operate the various types of pumps.

Pumps have two main purposes.

Ø Transfer of liquid from one place to another place (e.g. water from an underground into a water storage tank).

Ø Circulate liquid around a system (e.g. cooling water or lubricants through machines and equipment).

29.2 Components of a Pumping System

· Pump casing and impellers

· Prime movers: electric motors, diesel engines or air system

· Piping used to carry the fluid

· Valves, used to control the flow in the system

· Other fittings, controls and instrumentation

· End-use equipment, which have different requirements (e.g. pressure, flow) and therefore determine the pumping system components and configuration. Examples include heat exchangers, tanks and hydraulic machines.

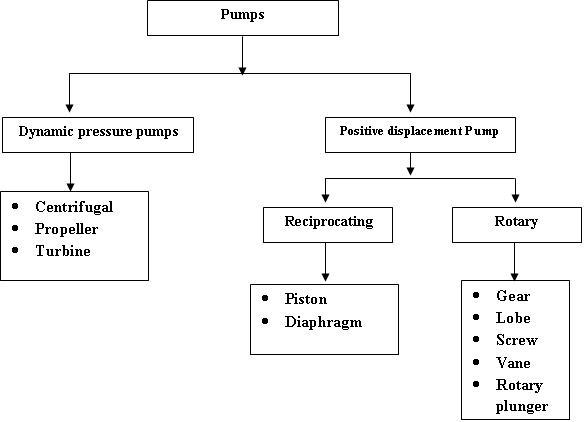

29.3 Classification

There exist a wide variety of pumps that are designed for various specific applications. However, most of them can be broadly classified into two categories as mentioned below.

i. positive displacement

ii. dynamic pressure pumps

Fig. 29.1 Classification of pumps

29.4 Positive Displacement Pumps

The term positive displacement pump is quite descriptive, because such pumps are designed to displace a more or less fixed volume of fluid during each cycle of operation. The volumetric flow rate is determined by the displacement per cycle of the moving member (either rotating or reciprocating) times the cycle rate (e.g. rpm). The flow capacity is thus fixed by the design, size, and operating speed of the pump. The pressure (or head) that the pump develops depends upon the flow resistance of the system in which the pump is installed and is limited only by the size of the driving motor and the strength of the parts. Consequently, the discharge line from the pump should never be closed off without allowing for recycle around the pump or damage to the pump could result. They can be further classified as:

29.5 Types of Positive Displacement Pumps

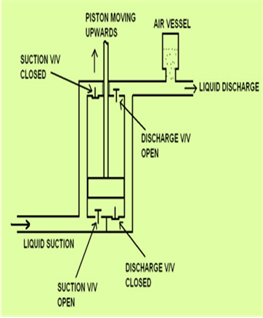

29.5.1 Reciprocating pumps

Pumping takes place by to and fro motion of the piston or diaphragm in the cylinder. It is often used where relatively small quantity of liquid is to be handled and where delivery pressure is quite large.

Piston pump: A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. The pump has a piston cylinder arrangement. As the piston, goes away after the delivery stoke, low pressure is created in the cylinder which opens the suction valve. On forward stoke, the fluid filled inside the cylinder is compressed which intern opens the delivery valve for the delivery of liquid.

Fig. 29.2 Piston pump

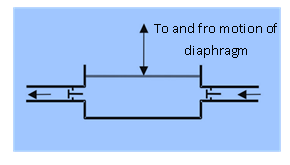

Diaphragm pump: uses a combination of the reciprocating action of a rubber, thermoplastic or Teflon diaphragm and suitable non-return check valves to pump a fluid. Sometimes this type of pump is also called a membrane pump.

Fig. 29.3 Diaphragm pump

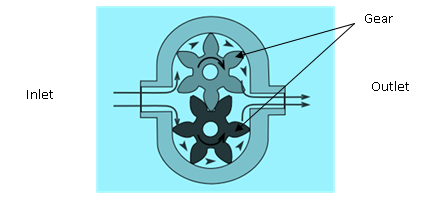

29.5.2 Rotary pumps

In rotary pumps, relative movement between rotating elements and the stationary element of the pump cause the pumping action. The operation is different from reciprocating pumps, where valves and a piston are integral to the pump. They also differ from centrifugal pumps, where high velocity is turned into pressure. Rotary pumps are designed so that a continuous seal is maintained between inlet and outlet ports by the action and position of the pumping elements and close running clearances of the pump. Therefore, rotary pumps do not require valve arrangements similar to reciprocating pumps.

Gear pumps: uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The rigid design of the gears and houses allow for very high pressures and the ability to pump highly viscous fluids.

Fig. 29.4 Gear pump

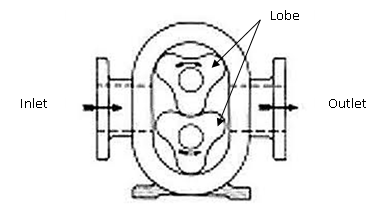

Lobe pump: Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. As the lobes come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the lobes as they rotate. Liquid travels around the interior of the casing in the pockets between the lobes and the casing. Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

Fig. 29.5 Lobe pump

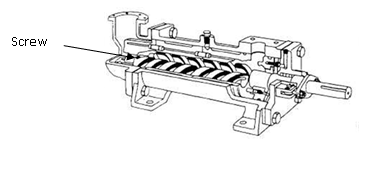

Screw Pump: These

pumps are rotary, positive displacement pumps that can have one or more screws

to transfer high or low viscosity fluids along an axis. Although progressive

cavity pumps can be referred to as a single screw pumps, typically screw pumps

have two or more intermeshing screws rotating axially clockwise or counterclockwise. Each screw thread is matched to

carry a specific volume of fluid. Screw pumps provide a specific volume

with each cycle and can be dependable in metering applications.![]()

Fig. 29.6 Screw pump

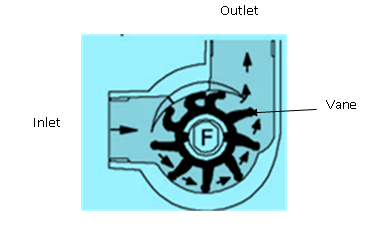

Vane pump: A rotary vane pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside of a cavity. In some cases, these vanes can be variable length and/or tensioned to maintain contact with the walls as the pump rotates.

Fig. 29.7 Vane pump

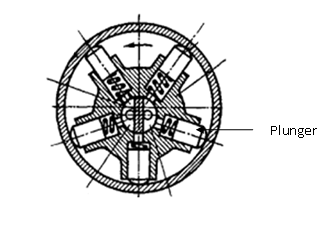

Rotary plunger pump: The pumping action takes place by rotating rotor and reciprocating plunger. In a rotary plunger rotary pump, the axes of the plungers are perpendicular to the rotational axis of the rotor or at an angle of not less than 45° to the axis; the rotor is located eccentrically with respect to the axis of the case.

Fig. 29.8 Rotary plunger pump

Suction and forced delivery of the liquid occur with the reciprocating motion of the plungers as a result of centrifugal forces and spring action. Rotary pumps of this type may have as many as 72 plungers arranged in multiple rows, provide a delivery Q ≤ 400 liters/min, and build up a pumping pressure ρ ≤ 100 MN/m2 .

29.6 Dynamic Pressure Pumps

In dynamic pressure pump, during pumping action, tangential force is imparted which accelerates the fluid normally by rotation of impeller. Some systems which contain dynamic pump may require positive displacement pump for priming. They are normally used for moderate to high discharge rate. The pressure differential range for this type of pumps is in a range of low to moderate. They are popularly used in a system where low viscosity fluids are used.

29.6.1 Centrifugal pumps

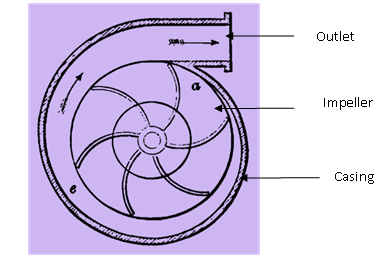

They use a rotating impeller to increase the pressure of a fluid. Centrifugal pumps are commonly used to move liquids through a piping system. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from where it exits into the downstream piping system. Centrifugal pumps are used for large discharge through smaller heads. These types of pumps are used for supply of water and handling of milk in dairy plants.

Fig. 29.9 Centrifugal pump

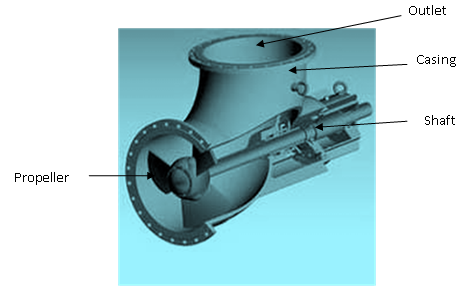

29.6.2 Propeller pump

A propeller pump is a high flow, low lift impeller type device featuring a linear flow path. The propeller pump may be installed in a vertical, horizontal, or angled orientation and typically has its motor situated above the water level with the impeller below water. These pumps function by drawing water up an outer casing and out of a discharge outlet via a propeller bladed impeller head.

Fig. 29.10 Propeller pump

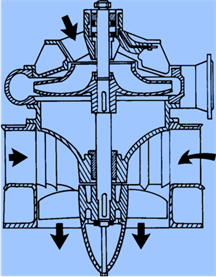

29.6.3 Turbine pump

Turbine pumps are centrifugal pumps that use pressure and flow in combination with a rotary mechanism to transfer fluid. They typically employ blade geometry, which causes fluid circulation around the vanes to add pressure from inlet to outlet. Turbine pumps operate using kinetic energy to move fluid utilizing an impeller. The centrifugal force drives the liquid to the housing wall in close proximity to the vanes of the impeller or propeller. The cyclical movement of the impeller produces pressure in the pumping bowl. The shape of turbine pumps also contributes to suction and discharge rates.

Fig. 29.11 Turbine pump