Module 10. Pumps

Lesson 30

RECIPROCATING PUMPS

30.1 Introduction

Reciprocating pumps create and displace a volume of liquid by the action of a reciprocating element. The pump consists of cylinder, piston or plunger and drive arrangement for to and fro motion of the piston. These pumps are called positive displacement pump as they delivers volume of the fluid filled in the cylinder irrespective of the delivery head and develops higher pressure as compared to centrifugal pumps. However, liquid discharge pressure is limited only by strength of structural parts. A pressure relief valve and a discharge check valve are normally required for reciprocating pumps. Reciprocating pump is used in milk homogenizer in dairy industry in order to develop high pressure. Reciprocating pumps can be further classified into two types, as given below.

i) Piston Pumps

ii) Diaphragm Pumps

30.2 Piston Pump

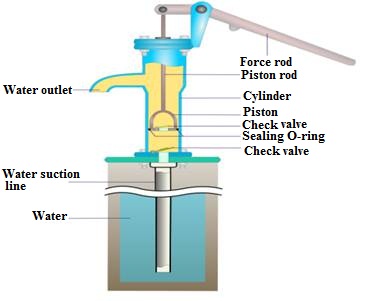

Hand pump is a simplest form of piston pump used in villages for lifting water from the tube well. Though, these pumps are replaced by sub-mersible electrically operated pumps even in villages. The piston pump is one of the most common reciprocating pumps for a broad range of applications prior to the development of high speed centrifugal pumps. Reciprocating pumps are used in low flow rate applications with very high pressure.

Fig. 30.1 Hand pump

30.2.1 Working of reciprocating pump

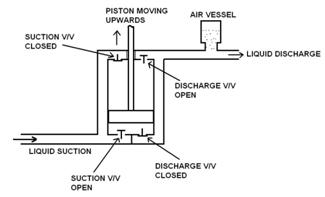

Fig. 30.2 shows a single acting reciprocating pump having piston which moves forwards and backwards in a close fitting cylinder. The movement of piston in the cylinder is obtained by connecting the piston rod to crank by means of connecting rod. The crank is rotated by means of an electric motor. The suction and delivery valves are suitably placed which are one way valves.

As the crank rotates from A to C (θ = 0° to θ = 180°), the piston moves towards right in the cylinder. This creates partial vacuum in the cylinder. As the pressure on the water surface is higher, the liquid enters the cylinder through suction valve. The movement of piston from C to A (θ = 180° to θ = 360°), closes the suction valve and opens delivery valve and the liquid is forced in the delivery pipe.

Fig. 30.2 Working and main parts of reciprocating pump (single acting)

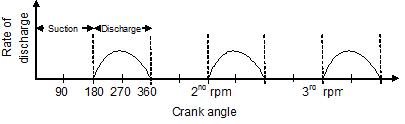

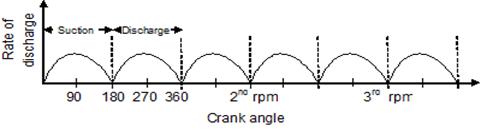

The reciprocating pumps are further classified as single acting and double acting. In case of single acting pump as shown in Fig. 30.2, the pump delivers one effective discharge stoke per one revolution of the crank (i.e. one suction stoke and one delivery stroke). Double acting reciprocating pump has suction valve and delivery valve on both the sides of the piston as shown in Fig. 30.3.

Fig. 30.3 Working of double acting piston pump

The single acting pump discharges water only on its forward stroke while the double acting pump discharges on its return stroke as well.

30.2.2 Capacity of reciprocating pump

The

capacity (Q) of a single acting piston or plunger pump is proportional to its

displacement per unit time. The displacement is the calculated capacity of the

pump, assuming 100% hydraulic efficiency, and is proportional to the cross

sectional area of the piston (A), the length of its stroke (L), the number of

cylinders (n), and the speed (N) of the pump (r.p.m.

of the crank).

![]()

It is obvious that the rate of discharge will be double neglecting the volume of piston rod in case of double acting pump.

The actual discharge under field conditions will be less as compared to theoretical discharge. The difference between actual discharge and theoretical discharge of the pump is called slip of a pump. It is expressed as % slip which is given by:

![]()

![]()

The major component of slip is the leakage of fluid back through the discharge or suction valve as it is closing (or seated). It can reduce calculated displacement from 2 to 10% depending upon valve design and condition. Another important factor that affects a capacity of reciprocating pump is called volumetric efficiency (VE). VE is expressed as a percentage and is proportional to the ratio of the total discharge volume to the piston or plunger displacement.

The ratio (r) is shown to be (c+d)/d where d is the volume displaced by the piston or plunger and c is the additional volume between the discharge and suction valves. The smaller is this ratio, the better the volumetric efficiency. Expressed mathematically as:

VE = 1 - (P × b × r) – S

Where, P is pressure, b is the liquid’s compressibility factor, r is the volume ratio, and S is slip. The compressibility factor for water is quite small but at pressures greater than 10,000 PSI it does become a factor. Although there is no cylinder wall around the plunger at the bottom of its stroke, it still displaces fluid equal to its own volume. The actual capacity of the pump is given by:

Qact = Qth × VE

30.2.3 Power requirement for reciprocating pump

The work done by reciprocating pump is given as under:

work done/second = (weight of water

lifted/second)*(total height through which water is lifted)

![]()

30.2.4 Simplex and duplex pumps

A simplex pump, sometimes referred to as a single pump, is a pump having a single liquid (pump) cylinder. A duplex pump is the equivalent of two simplex pumps placed side by side on the same foundation. The driving of the pistons of a duplex pump is arranged in such a manner that when one piston is on its upstroke the other piston is on its downstroke, and vice versa. This arrangement doubles the capacity of the duplex pump compared to a simplex pump of comparable design.

30.2.5 Triplex pump

A positive-displacement reciprocating pump that is configured with three plungers. Generally milk homogenizer are of triplex type.

Fig. 30.4 Triplex pump

30.3 Diaphragm Pumps

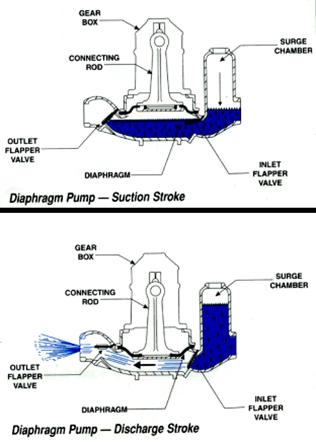

Diaphragm pumps are reciprocating positive displacement pumps that employ a flexible membrane instead of a piston or plunger to displace the pumped fluid. They are truly self priming (can prime dry) and can run dry without damage. They operate via the same volumetric displacement principle described earlier.

Fig. 30.5 Diaphragm pump

Were its operation any simpler, it would compete with gravity. The upper portion of the figure shows the suction stroke. The handle lifts the diaphragm creating a partial vacuum which closes the discharge valve while allowing liquid to enter the pump chamber via the suction valve. During the discharge stroke the diaphragm is pushed downward and the process is reversed.

You will note that, unlike pistons and plungers, diaphragms do not require a sealing system and therefore operate leak free. This feature does, however, preclude the possibility of a double acting design. If nearly continuous flow is required, a double-diaphragm or duplex pump is usually employed. The figure below is a cross section of an air operated, double diaphragm pump.

The double diaphragm pump utilizes a common suction and discharge manifold teamed with two diaphragms rigidly connected by a shaft. The pumped liquid resides in the outside chamber of each while compressed air is routed to and from their inner chambers. In the figure, the right hand chamber has just completed its suction stroke and, simultaneously, the left chamber completed its discharge stroke. As would be expected, the suction check is open so that liquid can flow into the right chamber and the discharge check of the left chamber is open so that liquid can flow out. Except for the double chamber configuration, its operation is just like the double acting piston pump seen earlier. The difference, of course, resides within the inner chambers and the method in which the reciprocating motion is maintained. This is accomplished by an air distribution valve that introduces compressed air to one diaphragm chamber while exhausting it from the other. Upon completion of the stroke the valve rotates 90 degrees and reciprocation occurs.

Fig. 30.6 Single cylinder single acting pump

Fig. 30.7 (a) Single cylinder double acting pump or double cylinder single acting pump

Fig.

30.7 (b) Triplex single acting reciprocating pump