Module 1:

Fat Rich Dairy Products

Lesson 3

CLASSIFICATION, STANDARDS AND COMPOSITION OF CREAM

3.1 Introduction

Cream is the fatty portion of milk which rises to the top of milk on quiescent storage and is rich in fat. It is produced by separation of un-homogenized whole milk. The concentration of non-fat components (SNF) in cream is in the proportion to the amount of non-fat components transferred from the original milk from which cream is obtained. The indigenous product similar to cream is malai.

3.2 Legal Definition

According to Food Safety and Standards Regulations (FSSR) 2011, Cream including sterilized cream means the product of cow or buffalo milk or a combination thereof. It shall be free from starch and other ingredients foreign to milk. It may be of following three categories, namely:—

1. Low fat cream—containing milk fat not less than 25.0 percent by weight.

2. Medium fat cream—containing milk fat not less than 40.0 percent by weight.

3. High fat cream—containing milk fat not less than 60.0 percent by weight.

Note:- Cream sold without any indication about milk fat content shall be treated as high fat cream.

2.3 Classification

The fat in cream varies from 18-85%. As the fat percentage in cream increase the components of milk in cream gradually decreases. The SNF content constitutes lower proportions than present in milk. Broadly, cream may be classified into two groups:

1. Market Cream : The cream used for direct consumption

2. Manufacturing or Industrial Cream: It is used in production of various milk products.

Different types of cream following under these groups are:

|

Table cream |

|

20-25% milk fat |

|

Light cream |

||

|

Coffee cream |

|

30-45% milk fat |

|

Whipping cream |

||

|

Heavy cream |

|

65-85% milk fat |

|

Plastic cream |

2.4 Description of Cream as per Codex Alimentarius Commission

2.4.1 Cream is the fluid milk product comparatively rich in fat, in the form of an emulsion of fat-in-skimmed milk, obtained by physical separation from milk.

2.4.2 Reconstituted cream is cream obtained by reconstituting milk products with or without the addition of potable water and with the same end product characteristics as those of cream.

2.4.3. Recombined cream is cream obtained by recombining milk products with or without the addition of potable water and with the same end product characteristics as those of cream.

2.4.4 Prepared creams are the milk products obtained by subjecting cream, reconstituted cream and/or recombined cream to suitable treatments and processes to obtain the characteristic properties as specified below.

2.4.5 Prepackaged liquid cream is the fluid milk product obtained by preparing and packaging cream, reconstituted cream and/or recombined cream for direct consumption and/or for direct use as such.

2.4.6 Whipping cream is the fluid cream, reconstituted cream and/or recombined cream that is intended for whipping. When cream is intended for use by the final consumer the cream should have been prepared in a way that facilitates the whipping process.

2.4.7 Cream packed under pressure is the fluid cream, reconstituted cream and/or recombined cream that is packed with a propellant gas in a pressure-propulsion container and which becomes Whipped Cream when removed from that container.

2.4.8 Whipped cream is the fluid cream, reconstituted cream and/or recombined cream into which air or inert gas has been incorporated without reversing the fat-in-skimmed milk emulsion.

2.4.9 Fermented cream is the milk product obtained by fermentation of cream, reconstituted cream or recombined cream, by the action of suitable micro-organisms, that results in reduction of pH with or without coagulation. Where the content of (a) specific micro-organism(s) is(are) indicated, directly or indirectly, in the labelling or otherwise indicated by content claims in connection with sale, these shall be present, viable, active and abundant in the product to the date of minimum durability. If the product is heat-treated after fermentation the requirement for viable micro-organisms does not apply.

2.4.10 Acidified cream is the milk product obtained by acidifying cream, reconstituted cream and/or recombined cream by the action of acids and/or acidity regulators to achieve a reduction of pH with or without coagulation

In general, the following types of cream are relevant to market and industrial purposes:

§ Table Cream: This type of cream contained 18 to 22% fat and used for eating directly. Various food preparations are made from this cream as fruit cream etc.

§ Light Cream or Thin Cream: Fat percentage in this type of cream is about 20 to 25 and used for table purpose and for manufacturing of cream cottage cheese etc.

§ Coffee Cream: This is light or thin type fresh cream containing 18 to 25 percent fat. It is used mostly in coffee making. If this cream has any lactic acid, it becomes coagulated after adding to coffee. These cream coagulates are known as “Cream feathers”. This feathering may be prevented by addition of sodium citrate to this slight acidic cream. If the water which used in coffee making has more calcium, accelerate the cream feathering. The addition of 0.05% sodium citrate also reduces the hardness and thickness of cream plug in cream bottles.

§ Heavy Cream: This type of cream contains 30 to 40% fat and used in production of butter and ice cream. Sometimes it can be used in panner production.

§ Plastic Cream: The cream of 30-40% fat re-separated to obtain the cream of 80 per cent and this rich cream is known as plastic cream. Mostly this type of cream is used for ghee production. This cream can be produced directly from milk which is separated in an especially designed plastic cream separator.

§ Whipped Cream: When the normal cream (30-40% fat) is incorporated with air, the air bubbles are stabilized by protein adsorption. The fat globules are assemble around these air bubbles. As whipping continues, these air cells subdivided into smaller one each with adsorbed layer and in numerable fat globules. At the maximum stiffness, these smaller air cells (nuclei) are surrounded by films of adsorbed protein which is so thin that drainage is at a minimum and the structure of dry foam is set up. The favorable temperature for whipping is 10ºC. Over whipping may produces a buttery product. The cream pasteurization and sugar addition declines the whipping rate in cream. Some of the dairy plants used Nitrous oxide gas for cream whipping. Whipped cream is used in cakes and ice cream etc. for decorative purpose.

§ Sour Cream: This type of cream are produced by inoculating sweet, pasteurized and homogenized cream with a starter culture containing lactic acid producing and aroma producing microorganism and incubated to proceed fermentation. This cream has 0.6% lactic acid, clean flavour and smooth texture. Sometimes rennet can be added @ 0.03 ml/gal cream to get more firm product. Sour cream should be stored at 40ºF or less temperature to check the further increase in acidity.

§ Clotted cream: To obtain the clotted cream, milk is scalded for fifteen minutes at about 85-90 ºC in shallow pan and allowed to form a cream layer. Considerable evaporation occurs from the cream layer and on cooling over a period of twenty four hours, the clotted cream may be removed. The main difference between ordinary cream and clotted cream are the decreased ratio of SNF/water and relatively higher proportion of protein in the clotted cream.

§ Frozen Cream: Cream is frozen to improve its keeping quality. Pasteurize the ordinary cream (40-50% fat) at 77ºC for 15 minutes and packing in paper, plastic or tin containers after cooling at 4ºC or below. Freeze quickly this packaged cream and store at –12ºC or below. This stored cream is used during shortage in preparation of ice-cream etc. During storage the fat globule membrane may ruptured by ice crystals. Therefore, this cream tends to ‘Oil-off ‘on thawing. This ‘Oiling-off impairs the whipping characteristics of the ice cream.

§ Sterilized or Canned Cream: Homogenize the 20% cream at 80ºC using pressure 175 kg/cm2 in the first stage and 35 kg/cm2 in the second stage and cooled to 16°C immediately. Tri-sodium phosphate is added @ 0.2% as a stabilizer to the cream. This cream is packaged in tin cans or bottles and sterilized in following manner:

· Coming up time 15 Minutes to 114± 1ºC

· Holding time 15 Minutes to 114± 1ºC

· Cooling time 15 Minutes to room temperature

§ Reconstituted Cream: By vigorous emulsification of unsalted plain butter in milk or separated milk or reconstituted milk or condensed milk, the fat globules are dispersed and coated with a layer of adsorbed protein, the resulted product is closely resembles with cream and known are reconstituted cream.

§ Synthetic Cream: In the artificial cream, butter fat is substituted with margarine fat and resulted product is known as synthetic cream. Margarine is an imitation and substitute of butter. In production of synthetic cream, the refined oils are carefully blended to have some physical cream, the refined oils are carefully blended to have some physical properties resemble to butter fat. Synthetic cream may have some emulsifying agents such as egg yolk, vegetable lecithin and glycerol- Mono or di-stearated etc.

§ Whey Cream: Separation is sometimes used to remove fat from cheese whey and resulted cream is known as whey cream. It is slightly differs in composition from regular fresh cream obtained from milk.

3.3 Composition of Cream

Cream generally contains all the constituents of milk but non-fat constituents are inversely proportional to the fat content as show in table 3.1.

Table 3.1 Composition of cream

|

|

Cream with 30% fat |

Cream with 50% fat |

|

Water |

64.0% |

44.43% |

|

Fat |

30.0% |

50.00% |

|

Protein |

2.4% |

1.69% |

|

Lactose |

3.5% |

2.47% |

|

Minerals |

0.4% |

0.37% |

|

SNF |

6.3% |

4.53% |

SNF of cream can be calculated by taking the ratio of water to SNF of milk

If ratio of water to SNF

of milk is 10:1, then the approximate SNF in cream = (100 - F/11) where F is

fat content of cream. SNF in cream can be estimated as:

![]()

3.4 Physico-Chemical Properties

Some of the important physico chemical properties relevant to cream processing and consumption are discussed below:

3.4.1 Viscosity

It is the resistance offered by the liquid to flow. Consumer judges the richness of cream by its viscosity. The factors affecting the viscosity of cream are given below:

· Fat percentage: Higher the fat % greater is the viscosity.

· Temperature: Higher the temperature lower is the viscosity.

· Separation conditions: Higher temperature of separation lowers the viscosity.

· Homogenization: Homogenization increases the viscosity of cream. Single stage homogenization increases viscosity more than the double stage homogenization.

· Cooling: Cooling of cream increases the viscosity.

· Ageing: The viscosity of cream increases with storage period.

· Clumping: It refers to the tendency of fat globules to adhere loosely to one another and form clumps. Clumping depends on fat globule size, temperature (maximum at 7ºC), agitation and method of separation. The greater is the clumping, greater will be the viscosity.

3.4.2. Whipping quality

Whipping means emulsion of gas or foam production by beating of cream. Whipped cream has remarkable stability. This is used in cakes, ice creams and for decorative purposes. The most satisfactory fat content for production of whipping cream is 30-35%. The optimum aging period is 24 hours at 4°C. Homogenization, acidity and stabilizers in cream reduces the whip-ability of cream.

3.4.3. Titratable acidity (TA)

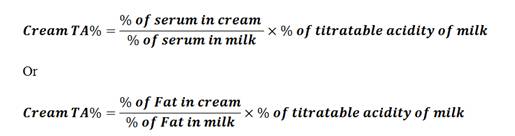

There is an inverse relationship between the percent fat and percent titratable acidity. Fresh cream has lower acidity percentage than milk.

Formula for Acidity:

3.4.4. Specific gravity

Specific gravity of cream is inversely proportional to the fat percentage as shown below:

|

Fat percentage in milk /cream |

Specific gravity |

|

0.025 4.0 6.0 10.0 20.0 30.0 40.0 |

1.037 1.032 1.030 1.025 1.013 1.003 0.995 |