Module

2.

Cream separator

Lesson 6

FACTORS AFFECTING

SKIMMING EFFICIENCY AND RICHNESS OF CREAM

6.1 Introduction

Normally the objective of separation is to attempt to recover all the fat in the whole milk within the cream fraction, with the minimum amount of fat being retained in the skim milk. Skimming efficiency is assessed as the fat content of the skim milk. If the skim milk is to be converted into skim powder or casein then it is important that the fat content be low, to meet various specifications and functional requirements of these products.

6.2 Factors Influencing the Fat Percentage of Cream

The important factors influencing the fat percentage of cream by centrifugal separation are discussed below:

6.2.1 Position of the cream screw

The cream screw/outlet consists of a small, threaded, hollow screw pierced by a circular orifice through which the cream emerges. This screw can be driven IN or OUT, thus bringing it nearer to, or away from, the centre of rotation. Similarly, the skim milk screw/outlet is for the removal of skim milk. Once the cream screw or skim milk screw has been adjusted, the cream separator delivers, under normal conditions, a definite ratio of skim milk and cream, which is usually 90:10 (or 85:15) by volume. Basically, any change in the separation procedures which alters the relative quantities of skim milk and cream will influence the fat test of the cream. By altering the position of the cream screw (or skim milk screw), the ratio of skim milk to cream changes. Thus, when the cream screw is moved IN towards the axis of rotation, a higher fat percentage in cream is obtained, and vice versa; this is because the force tending to discharge cream through the orifice is decreased ('R' in the formula F = KWRN2 is decreased),. A smaller proportion of cream is therefore discharged, which, contains the same quantity of fat, resulting in a higher fat percentage. Screwing OUT the cream screw produces thinner cream. Similarly, the skim milk screw OUT results in richer cream, and vice versa.

6.2.2 Fat percentage in milk

The higher the fat percentage in milk, the higher the per cent fat in cream, and vice versa. Since practically all the fat in milk is contained in the cream, the cream from the separation of high-fat milk has a higher fat content than that from low-fat milk; a greater fat content in cream, the amount of which remains unaltered in the two cases, will obviously show a higher fat percentage in it, and vice versa.

6.2.3 Speed of the bowl

The velocity of a fat globule is proportional to the square of the rotational speed so an increase in bowl speed will have a very major effect on separation efficiency. An increase in bowl speed however requires an increase in energy input and a more robust design to withstand the large forces at the bowl periphery. The separator also generates more noise. For this reason bowl speeds have not increased significantly as skimming efficiency is quite adequate at moderate speeds of 4000-6000 rpm. The higher the speed of the bowl, the higher will be the fat % in cream. The higher the speed of the bowl, the greater will be the centrifugal force and more rapidly the skim milk leaves the bowl with higher fat % in cream.

6.2.4 Rate of the milk flow

The higher the rate of milk inflow, the lower the fat percentage in cream, and vice versa. When the rate of inflow increases, the discharge from the cream outlet increases. As the skim milk discharge remains constant (with constant centrifugal force); more cream containing the same amount of fat results in a lower fat test, and vice versa.

6.2.5 Temperature of milk

An increase in temperature of milk leads to both an increase in density difference between milk fat and skim milk. So increase in temperature will lead to lower separation efficiency. Higher temperature will lead to disruption of fat globule which will result in heavy fat losses in skim milk. The fat losses are higher at 70°C than at 54.5°C. The optimum separation temperature is 40°C. Higher temperature leads to protein denaturation and phospholipids.

Cold milk separators that will operate at temperatures less than 10°C are available. These allow separation of milk as it is received at the factory, and although fat losses to skim milk are somewhat higher they do sometimes allow substantial savings in energy and capital costs. In some cheese making operations heat treatment of the milk is undesirable and cold milk separators offer some advantages. In addition cold milk separators produce cream with greater phospholipids content which gives better whipping properties. The major modification in a cold milk separator is wider disc spacing than in a conventional model to allow adequate flow of the more viscous cold cream.

6.2.6 Amount of water or skim milk added to flush the bowl

The greater the quantity of water or skim milk added to flush the bowl, the lower the fat percentage in cream, and vice versa. The addition of more water or skim milk will cause an increase in the amount of cream produced, which, with the same fat content, will show a lower fat test.

6.3 Factors Affecting Fat Losses in Skim Milk During Separation

6.3.1 Skimming efficiency

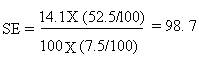

It refers to the % of total fat from milk recovered in the cream. The higher the fat % in milk, the greater the fat losses in the skim milk, the lower will be the skimming efficiency (SE) and vice versa. The best indication of higher SE is lower fat percentage in skim milk. SE of machine may be calculated using the following equation:

C X F/100

SE = __________ X 100

M X F1/100

Where,

C - Amount to cream (Kg)

F - Fat percentage in cream

F1 - Fat percentage in milk

M -Amount of milk (Kg)

Examples

1. Given: 100 kg milk testing 7.5% fat; cream produced 14.1 kg cream testing 52.5% fat. Calculating skimming efficiency (SE).

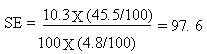

2. 100 kg milk testing 4.8% fat produced 10.3 kg cream testing 45.5% fat. Caluculate(SE)

Note. In the above examples, high fat-test milk shows a higher SE than low-fat-test milk.

6.3.2 Factors affecting fat losses in skim milk

The important factors influencing the fat losses in skim milk obtained through centrifugal separation are discussed below:

6.3.2.1 Temperature of milk

The lower the temperature of milk, the higher the fat losses in skim milk and vice versa. For efficient separation, the temperature of milk should be above the melting point of fat, so that the milk fat in the fat globules is entirely in liquid form. A satisfactory temperature for separation is around 40°C. The higher the temperature, the more efficient is the separation. There is no marked increase in efficiency after 43-49°C. On the other hand, separation at low temperatures (in warm-milk separators) may lead to partial clogging of the bowl due to high viscosity of cream at these temperatures, resulting in a greater fat loss in skim milk.

6.3.2.2 Speed of the separator bowl

The lower the speed of the bowl, the higher the fat loss in skim milk, and vice-versa. At below-rated speed there will be more fat loss in skim milk because insufficient centrifugal force is generated for efficient cream separation. However, at above rated speeds, the skimming efficiency will not increase greatly.

6.3.2.3. Rate of milk in-flow

The higher the rate of inflow of milk, the higher will be the fat losses in skim milk, and vice versa. If the rate of inflow is increased above the designed capacity of the separator, the milk passes through the bowl too rapidly and do not to allow for complete separation, thereby resulting in a higher fat loss in skim milk. On the other hand, underfeeding the separator does not greatly increase the efficiency of the separation.

6.3.2.4. Position of cream screw

A good separator is designed to give efficient skimming within a fairly wide range of positions of the cream screw, so that the fat test of the cream can be varied without influencing the efficiency of skimming. With most separators, the position of the cream screw has little effect on the fat test of skim milk until the cream test is above 45 to 50 per cent. From this point up to a 60 per cent fat test in cream, the fat content of the skim milk increases. Separation of very thick cream at low temperatures may lead to higher losses due to clogging of the bowl with viscous cream.

6.3.2.5 Mechanical

condition of the machine

Unsatisfactory mechanical condition of cream separator causes greater loss in skim milk.

§ Vibration of separator: This reduces the efficiency of separation by disturbing the currents of cream and skim milk. Vibration is caused by installation on an insufficiently firm foundation, the bowl being out of balance, bearings being worn out, the axis of rotation not exactly vertical, etc.

§

Condition of the discs: Discs in an unsatisfactory condition suffer a loss of skimming

efficiency due to the uneven flow of the counter-current streams of cream and

skim milk between them. An unsatisfactory disc is one which is out of shape,

dirty, scratched or rough.

6.3.2.6 Amount of

separator slime in the bowl

If too much slime accumulates, the fat loss in skim milk increases; this is caused not only by a disturbance in the even flow of the counter-currents of cream and skim milk, but by reduction in the centrifugal force (because of decrease in the 'effective' diameter of the bowl).

Separator slime (which is usually considered identical with clarifier slime) consists of the slimy mass which accumulates inside the bowl shell of the cream separator. It is made up of foreign matter, milk proteins, leucocytes, fragments of the secreting cells from the udder, fat calcium-phosphate and other minerals, bacteria and, occasionally, red blood corpuscles.

The average composition of separator slime is given in Table 6.1.

Table 6.1 Composition of separator slime

|

Constituent |

Moist Slime % |

Dry Slime % |

|

Water |

68.2 |

- |

|

Fat |

1.4 |

4.4 |

|

Protein |

25.3 |

79.6 |

|

Lactose |

1.8 |

5.6 |

|

Minerals |

3.3 |

10.4 |

(Source: Hunziker (1940))

6.3.2.7 Size of the fat globules

The greater the number of fat globules of less than 2 µm size, the higher the fat loss in skim milk and vice versa. Fat globules of less than 2 µm size usually enter the skim milk, as they are not subject to sufficient centrifugal force to be recovered in the cream.

6.3.2.8 Degree and temperature of separation

The higher the degree and temperature of agitation, the greater will be the loss of fat in skim milk and vice versa. Agitation of hot milk causes the disintegration of normal fat globules in to smaller ones which escape the effect of centrifugal force there by leading to more fat loss in skim milk.

6.3.2.9 Presence of air in milk

The greater the amount of air in milk the higher the fat losses in skim milk. If the milk delivered to the separator contains entrapped air bubbles, centrifugal force will disturb the counter-current streams of cream and skim milk between the discs, and lower the efficiency of separation. The effect of air in the milk is greater with hermetic than with non-hermetic cream separators.

6.3.2.10 Acidity of Milk

The higher the acidity of milk, the lower the efficiency of separation, the lower the stability of casein particles which in turn get precipitated and clog the bowl there by lowering the efficiency of separation.

6.4 Yield of Cream and Skim Milk

6.4.1 Yield of cream

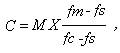

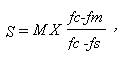

This can be calculated by the formula:

Edit Formula

Edit Formula

Where,

C = weight of cream (kg);

M = weight of milk (kg);

fm = fat percentage of milk;

fs = fat percentage of skim milk;

fc = fat percentage of cream.

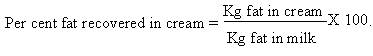

Fat recovery in cream: This can be calculated by the formula:

6.4.2 Yield of skim milk

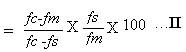

This can be calculated by the following formula:

Edit Formula

Edit Formula

Where,

S = weight of skim milk (kg);

M = weight of milk (kg);

fm = fat percentage of milk;

fs = fat percentage of skim milk;

fc = fat percentage of cream

Fat lost in skim milk: This can be calculated by the formula:

![]()

Where fc, fm and fs are as above.