Module 4. Fruits and vegetables juice processing

Lesson 12

GENERAL STEPS IN JUICE PROCESSING

12.1 Fruit Juice Processing

Juice and juice products represent a very important segment of the total processed fruit industry. Juice products are being marketed as refrigerated, shelf-stable, and frozen, in a variety of packages with increased emphasis on functionality, health attributes, new flavors or blends, and in some cases fortified with vitamins and minerals. High-quality juice operations are dependent upon a source of high-quality raw material.

Most fruit juices are excellent sources of vitamin C, several are good sources of carotene and many contain moderate amounts of pyridoxine, inositol, folic acid and biotin. Fruit juice is regarded as source of energy due to their rich carbohydrate content. The organic acids present in the fruit juice plays a significant role in the maintenance of the acid-base balance in the body.

The process starts with sound fruit, freshly harvested from the field or taken from refrigerated or frozen storage. Thorough washing is usually necessary to remove dirt and foreign objects and may be followed by a sanitation step to decrease the load of contaminants. Sorting to remove decayed and moldy fruit is necessary to make sure that the final juice will not have a high microbial load, undesirable flavors, or mycotoxin contamination. For most fruits, preparation steps such as pitting and grinding is required prior to juice extraction. Heating and addition of enzymes might also be included before the mash is transferred to the extraction stage. Juice extraction can be performed by pressing or by enzymatic treatment followed by decanting. The extracted juice will then be treated according to the characteristics of the final product.

For cloudy juices, further clarification might not be necessary or may involve a coarse filtration or a controlled centrifugation to remove large insoluble particles. For clear juices, complete de-pectinization by addition of enzymes, fine filtration, or high speed centrifugation is required to achieve visual clarity. The next step is usually a heat treatment or equivalent non-thermal process to achieve a safe and stable juice and final packaging if single-strength juice is being produced. For a concentrate, the juice is fed to an evaporator to remove water until the desired concentration level is obtained. Other processes used for water removal include reverse osmosis and freeze concentration, which are best suited for heat-sensitive juices. The concentrate is then ready for final processing, packaging, and storage.

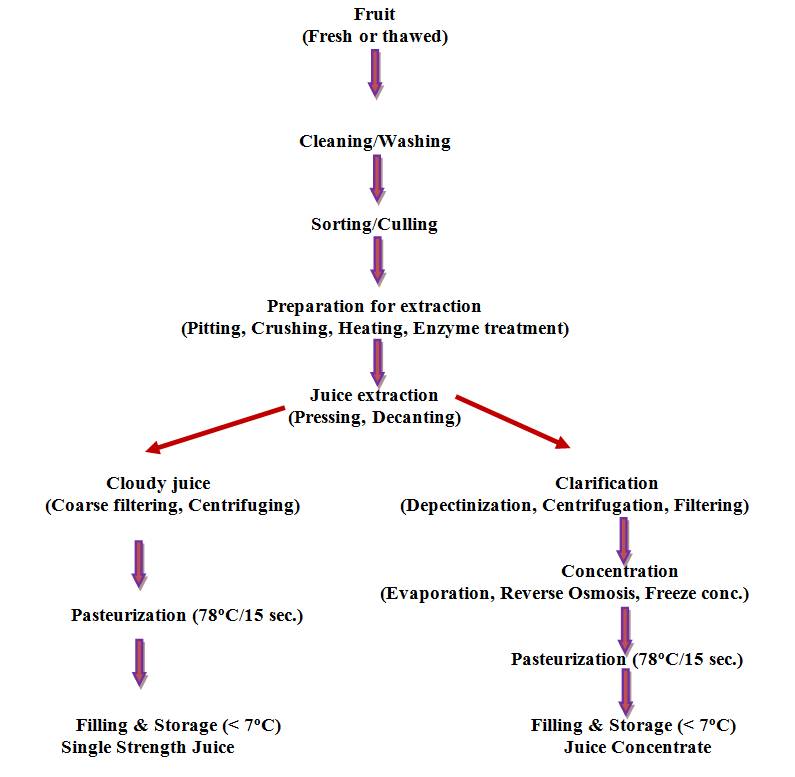

The generalized flow chart for preparing fruit juice is shown in Figure 12.1.

Fig.12.1 Generalized flow chart for fruit juice production

12.2 Significance of Few Important Steps in Fruit Juice Production

12.2.1 Straining/Filtration/Clarification

- Extracted fruit juice contains

varying amount of suspended solids – broken fruit tissue, seed, skin &

various gums, pectic substances and proteins in

colloidal suspension.

- Coarse particles removed by

straining (non-corrodible metallic screens) or sedimentation.

- If clear juice required (grape,

apple, lime juice cordial) complete removal of

all suspensions effected through filtration or clarification with the help

of fining agents and enzymes.

- Fining agents (i) Enzymes (pectolytic,

starch liquefying, proteolytic), (ii) Mechanical finings (Infusorial earth), (iii) Chemical finings (Gelatin,

albumin, casein).

- Apple juice – 0.5-1.5 oz. of

tannin and 1.5-6.0 oz. of gelatin per 100 gal. of

juice – fining purpose.

12.2.2 Disintegration

Juicing process starts with crushing, a step to break down the cell tissue. This may be accomplished using various type of mills viz., hammer mill, grinding disk mill, grating mill, crushers, stoned fruit mill or even turbo extractors.

12.2.3 Hot break process

In order to maximize juice yield and color-flavour extraction, a hot break process is often used.

12.2.4 Mash enzyme treatment

This step might not be used for the production of high quality, single-strength, cloudy and clear

juices, where the preservation of the fresh flavor is imperative. Depectinization is designed to reduce the viscosity and slipperiness of the pulp and thus permit the effective use of decanters and presses with proper press aids as needed. It is especially useful in processing mature and stored fruit that results in low juice yield.

12.2.5 Fruit juice extraction process

Hydraulic rack and frame press is the most common batch press system used in small scale operations. Other type of extractors include horizontal piston press, bladder press, belt press, screw press or even decanter centrifuge.

12.2.6 Deaeration

Pure orange juice which is extremely susceptible to the adverse action of the residual air, is subjected, immediately after extraction, to a high vacuum whereby most of the air as well as other gases are removed.

12.3 Role of Enzymes in Fruit Juice Extraction

The use of enzymes in juice industry has contributed in increasing the yield and production of various types of juices. The addition of pectinases aims in particular to degrade the pectic substances, in the cell wall and middle lamella of the cells of plants, aiming to minimise the impacts of these compounds on the characteristics of the final product, such as colour, turbidity and viscosity.

Enzymes are also able to remove bitterness of citrus juice, extract pigments, among other applications, and have also had great interest in the juice industry.

12.3.1 Pectinase, cellulase and hemicellulase

Pectinases, cellulases and hemicellulases are used for clarification of fruit juices, juice extraction, improvement of cloud stability of vegetable and fruit juices and nectars, liquefaction and maceration of fruits and vegetables, reduction of cooking time of pulses and improvement of rehydration characteristics of dried vegetables.

These enzymes degrade structural polysaccharides that interfere with juice extraction, filtration, clarification and concentration. These enzymes are termed ‘macerating or mash enzymes’ that finds application in extraction of juice from citrus fruits and from tropical fruits such as mango, banana and papaya and pineapple. For Apple and Pears, pectic enzymes are used to facilitate pressing or juice extraction, to aid in separation of flocculent precipitate by sedimentation, filtration or centrifugation.

Combination of pectinolytic enzymes are added to fruit and pressed fruit juice to reduce juice viscosity. Such viscosity reduction makes juice filtration, clarification and concentration more efficient. In concentrated fruit systems, it improves the efficiency of spray drying.

Aspergillus niger and A. oryzae produces mixture of pectinolytic enzymes.

12.3.1.1 Pectinases

The two well recognized types of pectolytic enzymes are pectinesterase and polygalacturonase, the actions of which is shown below:

pectinesterase

Pectin ![]() Methanol

+ Polygalacturonic acid

Methanol

+ Polygalacturonic acid

Polygalacturonase

Polygalacturonic

acid ![]() Galacturonic

acid

Galacturonic

acid

Most commercial pectinase enzymes are mixtures of these and probably other enzymes. Commercial pectolytic enzyme preparations containing predominantly polygalacturonase (PG) and pectin and pectate lyase (PLs) are utilized.

Liquefaction is accomplished using both pectolytic and cellulolytic enzymes in combination, taking advantage of observed synergistic effects.

Pectins are colloidal in nature, making solutions viscous and holding other materials in suspension. Pectinesterase removes methyl groups from the pectin molecules exposing carboxyl groups which in the presence of bi- or multivalent cations, such as calcium, form insoluble salts which can readily be removed. At the same time, polygalacturonase degrades macromolecular pectin, causing reduction in viscosity and destroying the protective colloidal action so that suspended materials will settle out.

Extensive use of pectolytic enzymes is made in processing fruit juices. Addition of pectic enzymes to grapes or other fruits during crushing or grinding results in increased yields of juice on pressing. Wine from grapes so treated will usually clear faster when fermentation is complete, and have better color.

Pectic enzymes are necessary for making high density fruit juice concentrates or purees. If apple juice is concentrated to 72oBrix without removal of the naturally occurring pectin, a gel will result rather than the desired liquid concentrate. In most cases, juices are depectinized and filtered before concentration, but in others the pectinase is allowed to act while the juice is being concentrated.

12.3.1.2 Cellulases

Commercial cellulase products capable of hydrolyzing nonpectin polysaccharides such as cellulose, glucans, and xylans are used to fractionate the cell walls and liquefy the remaining solids.

12.3.1.3 Naringinase and Limoninase

Naringinase and Limoninase have been used to hydrolyze naringin and limonin – the bitter compounds that are found in grapefruit juice.

12.3.1.4 Amylase and Arabinase

Starch and araban imparts a cloudy appearance called ‘haze’, when released into the juice from certain fruits. Hazes due to starch are common in juice from early season apples and can be degraded by amylases.

Although araban is not a problem in extracted juice, it produces a permanent haze in concentrated juices, where it has limited solubility. Arabinase can be used to hydrolyze araban so that haze does not develop during storage of juice concentrates.

12.4 Clear Fruit Juice

Juices extracted from ripe fruit contain a significant amount of pectin. Pectin imparts a cloudy appearance to the juice and results in an appearance and mouth feel that many consumers do not find appealing. Pectinases are naturally occurring enzymes that act on pectin yielding a crystal clear juice with the appearance, stability, mouth-feel, taste, and texture characteristics preferred by consumers. While pectinases naturally occur in most fruits used to make juice, the manufacturer often adds more to produce clear juice in a reasonable amount of time.

Most consumers prefer clear fruit juices. The cloud, such as in fresh Cider, is usually material held in suspension by pectin and filtration is difficult. The safest way to accomplish pectin removal without affecting color or flavor is to treat the juice with a pectic enzyme. Juice for jelly manufacture is frequently depectinized since more uniform jelly can be achieved when a standard amount of pectin is added in controlled amounts. The variable quality and quantity of the natural pectin in the juice does not interfere when it is treated with pectinase enzyme.

12.5 Benefits in the use of enzymes

- Increased juice yield

- Improved efficiency of juice

filtration

- Improved juice stability and

concentration

- Enhanced juice clarity

- Reduced juice bitterness

12.6 FSSA specifications for various fruit juices

Table 12.1 FSSA specifications for various fruit juices

|

No. |

Juice type |

TSS ( %), Min. |

Acidity expressed as citric acid (%), Max. |

Nutritive Sweetener ( g/kg), Max. |

|

1. |

Apple Juice |

10 |

3.5 (as malic acid) |

- |

|

2. |

Orange Juice a) Freshly expressed b) Reconstituted from concentrate |

10 10 |

3.5 3.5 |

50 - |

|

3. |

Grape Fruit Juice |

9 |

- |

50 |

|

4. |

Lemon juice |

6 |

4.0 Min. |

200 |

|

5. |

Lime juice |

- |

5.0 Min. |

200 |

|

6. |

Grape Juice a) Freshly expressed b) Reconstituted from concentrate |

15 15 |

3.5 3.5 |

- |

|

7. |

Pineapple Juice a) Freshly expressed b) Reconstituted from concentrate |

10 10 |

3.5 3.5 |

50 - |

|

8. |

Black Currant |

11 |

3.5 |

200 |

|

9. |

Mango, Guava or any other pulp fruit |

15 |

3.5 |

GMP |

|

10. |

Other fruit juices of single species (not very acidic) |

10 |

3.5 |

50 |

|

11. |

Other fruit juices of single species (very acidic) |

10 |

3.5 |

200 |

|

12. |

Other fruit juices of single species or combination thereof (not very acidic) |

10 |

3.5 |

50 |

|

13. |

Other fruit juices of single species or combination thereof (very acidic) |

10 |

3.5 |

200 |

12.7 Problems encountered during fruit juice processing

Some of the problems that may be faced in preparation of fruit juices are:

- Browning of juice due to action of enzyme Poly phenol oxidase inherent in fruit (i.e. Apples).

- Foaming of fruit juice that may lead to oxidation of vitmin C and pose problem during filling of juice in

packages.

- Bitterness of juice due to action of enzyme limonin and naringinase

(e.g. in Orange).

- Cloudy juices due to pectinaceous substance (apple juice) or even bitartrates (i.e. argol

precipitation) (i.e. in grape juice).