Module

6. Tomato and tomato-based products

Lesson 22

TOMATO

PUREE, PASTE, SAUCE AND KETCHUP

22.1 Manufacturing of Tomato Puree and Paste

The pulp which is obtained by hot or cold break method is concentrated to manufacture puree and paste. Fully mature and deep red coloured tomatoes are preferred for the manufacture of tomato puree and paste.

22.2 Tomato Puree

Tomato juice or pulp as obtained by cold or hot extraction method is concentrated to about 9.0 percent to 12.0 percent total solids to prepare tomato puree. Commercial tomato puree can be defined as concentrated tomato juice or pulp without skin or seeds, with or without added salt and containing not less than 9.0 percent salt free tomato solids, is “medium tomato puree”. Further concentration to 12.0 percent solids will yield “heavy tomato puree”.

22.3 Tomato Paste

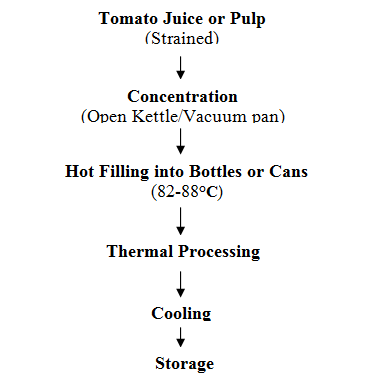

Tomato paste can be defined as concentrated tomato juice or pulp without skin and seeds, and containing not less than 25 percent of tomato solids. If the tomato paste is further concentrated to a tomato solid levels of 33 percent or more then it is called as concentrated tomato paste. The manufacturing technology for the production of tomato puree and paste is outlined in Fig. 22.1.

Fig.

22.1 Process flow diagram for tomato puree or paste

manufacture

Fig. 22.2 Tomato puree (A) and Tomato paste

(B)

Tomato juice or pulp is strained or filtered to remove portions of skin, seeds and large coarse pieces to get uniform juice or pulp. The juice or pulp is concentrated in open kettle or vacuum kettle to evaporate water and the process of evaporation in case of puree is continued till the volume reduced to equal or one-half of original. The end point is determined by the hand refractometer to measure the total soluble solids and expressed as degree Brix. Alternatively it can also be determined by using specific gravity bottle or by drying the juice or pulp under vacuum at 70°C. The puree of desired total soluble solids is then filled into cans (temperature of filling 82-88°C) and processed in boiling water for 20 min. The processed cans are cooled immediately either by dipping them in cold water or sprinkled with cold water. The cans are then stored in dry and cool place.

For the manufacture of tomato paste, tomato juice or pulp is first concentrated in open steam jacketed kettle to total solid levels in the range of 14-15 percent and subsequent concentration is carried out in vacuum pan. During cooking in open kettle common salt, basil leaf or sweet oil of basil leaf may also be added to prevent the excessive foaming, burning and sticking. In vacuum pan, the water present in pulp or juice starts evaporating at 71°C. It assists in retention of bright red colour and flavour. The removal of air also check any oxidative reaction that may adversely affect the nutritional value i.e. vitamin C. For sterilization of the product, vacuum is removed and the temperature is raised to 100°C and held at that temperature for about 10 min.

22.4 Technology of Tomato Ketchup and Sauce

Among the tomato products, in India tomato sauce and ketchup are very popular and are being manufactured on an increasingly large scale. It is one of the simplest ways of conserving the tomato solids. As per FSSA standards “Tomato ketchup and sauce means the product prepared by blending tomato juice/puree/paste of appropriate concentration with nutritive sweeteners, salt, vinegar, spices and condiments and any other ingredient suitable to the product and heating to the required consistency. Tomato paste may be used after dilution with water suitable for the purpose of maintaining the essential composition of the product. The finished product should contain not less than 25.0 percent total soluble solids (salt free basis) and acidity not less than 1.0 percent as acetic acid. The product should also meet the given microbiological criteria (Table 22.1).

Table 22.1 Microbiological criteria for tomato ketchup and tomato sauce

|

Tomato Ketchup and Tomato Sauce |

Mould count |

Positive in not more than 40.0 percent of the field examined |

|

Yeast and spore count |

Not more than 125 per 1/60 c.m.m |

|

|

Total plate count |

Not more than 10000 per ml |

Tomato ketchup and sauce can be made from freshly extracted juice or pulp or using tomato puree or paste. Strained tomato juice or pulp along with spices, salt, sugar and vinegar is cooked or concentrated to the extent that ketchup and sauce contains not less than 12 percent tomato solids, 25 percent total solids and minimum acidity as 1% acetic acid. The TSS content in tomato ketchup should be 25-29 for grade C, 29-33 for grade B and over 33 for grade A.

Basically there is no difference between tomato ketch-up and tomato sauce. Tomato sauce has thinner consistency and it is blended with juice or pulp from other vegetable sources including potato puree, cucumber juice or carrot pulp. In the manufacture of tomato ketchup following steps are involved:

22.4.1 Selection of raw material

Careful selection of tomato for the manufacture of tomato ketchup is very crucial step as it may affect the quality as well as shelf-life of the finished product. The criteria for selection include maturity, freedom from blemishes and defects. Ripe deep red coloured tomatoes with higher TSS and pulp provide a better quality product. Pectin content and pigmentation are two important parameters determined the finished product quality.

All green and yellow coloured portions should be removed. Chlorophyll and Xanthophyll present in immature fruits, upon heating form brown coloured compound pheophytin that may adversely affect the acceptability of the product. Flavour of the product also gets affected, if green tomatoes are used.

22.4.2 Extraction of pulp or juice

The pulp or juice could be extracted by using hot or cold pulping method. However, hot pulping method yields pulp with higher proportion of total solids, lycopene; pectin content and of good microbiological quality. The freshly extracted pulp or juice as well as preserved pulp or puree or paste may be used as starting material. Use of puree or paste of suitable total solid level produce ketchup of uniform quality and also ensure consistency from batch to batch.

22.4.3 Juice standardization

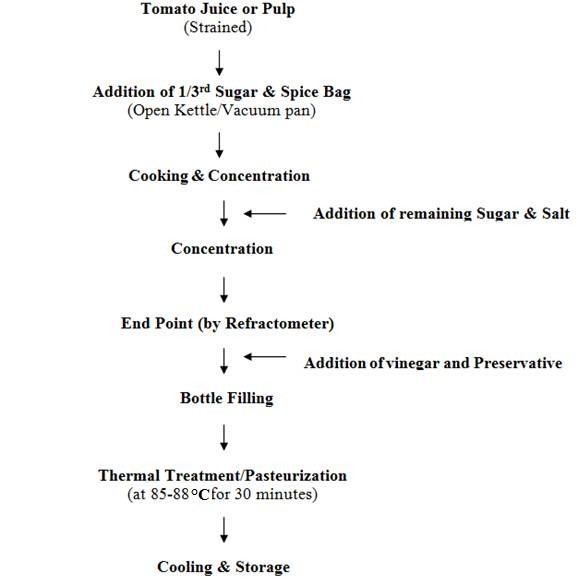

Freshly squeezed juice is a thin, watery fluid and its specific gravity varies with the kind of tomato and duration of boiling. Its T.S.S. should not be below 5.66°Brix. In case of tomato puree or paste these are diluted to desired total solid level before ketchup preparation. After standardization of juice or pulp total solid the ketchup or sauce is manufactured by the process as outlined in Fig. 22.2.

Fig.

22.3 Process flow diagram for tomato ketchup or sauce manufacture

Fig. 22.4 Tomato ketchup and tomato sauce

22.4.4 Addition of ingredients

22.4.4.1 Spices

The spices should be of good quality and they should be added in the proper proportions to give an agreeable taste and flavour to the product. No single spice dominates the natural flavour of the tomato. The spices which are preferred in ketchup manufacture include red chili, black pepper, nutmeg, clove, cinnamon, cardamom, mace and cumin. Beside these spices seasonings like onion, ginger and garlic may also be used in ketchup recipe. While adding spice certain precautions are recommended to produce excellent quality ketchup or sauce.

· Red chili powder, spices, onion and ginger should be tied loosely in bag for better diffusion of flavoring principles in ketchup.

· The head portion of clove should always be removed before its grinding as it may lead to black neck defect in ketchup.

· Normally garlic is not preferred seasoning in ketchup or sauce manufacture as its flavour may predominate over other spices.

· Essence of clove, cinnamon and cardamom is preferred in place of using coarsely ground powder because of the convenience of use and better flavour note in finished product.

The spices may be used in the following way during the manufacture of ketchup or sauce.

22.4.4.1.1 Bag method

The coarsely ground spices are tied loosely in a muslin cloth bag and the bag placed in the tomato juice during boiling. The bag is pressed intermittently to release the flavouring component during processing. The proportion these spices should be standardized in such a way that they should not affect the colour of the resultant product and does not impart bitterness. This bag can be used for second batch also. This method has following drawbacks:

- By

chance opening of bag may spoil the whole batch. Even if we want to remove

these, spice particles by passing it through sieve, it may darken the

product.

- Incomplete

extraction of flavouring component, so, flavour of ketchup may vary from

batch to batch.

- Some

of the volatile constituents may get lost during boiling.

Still bag method yield ketchup of superior quality and it is most preferred for ketchup or sauce preparation at small scale or batch methods. The spice bag may also be used for subsequent batches and used spices may also be in pickle preparation.

22.4.4.1.2 Use of essential oils

An essential oil is a concentrated hydrophobic liquid containing volatile aroma compounds from spices. They are extracted by the process of distillation or solvent extraction. The Essential oils of spices contain only the volatile substance of the spice and devoid of tannins, hence the colour and flavour of ketchup is not affected. These can be easily blended and precision in terms of percentage can be made. However, they lack the true aroma of the whole spice. The actual amount of essential oil for raw spice is mentioned below.

Table 22.2 Essential oil content in different spices

|

S. No. |

Spice (100 kg) |

Equivalent Weight of Essential Oil (kg) |

|

1 |

Cinnamon |

0.5 |

|

2 |

Clove |

1.5 |

|

3 |

Mace |

3.5 |

|

4 |

Pepper |

1.0 |

|

5 |

Cardamom |

3.0 |

22.4.4.1.3 Use of oleoresins

Oleoresins are pure and natural extracts of spices, obtained by solvent extraction. These concentrated extracts contain all the flavour components, be it volatile oils or non-volatile resinous fractions. These are the resins of active flavouring component in some solvent. The active flavouring molecule is extracted with a suitable solvent and it can provide the full flavour profile of the raw spice with quick release of the flavour. Application of oleoresins is advantageous in commercial production of ketchup or sauce. The only limitation while using oleoresin is the cost of production. Oleoresins are added few minutes before the final boiling during the manufacture of ketchup or sauce.

22.4.4.1.4 Use of extracts

Spice extract is prepared on large scale by steeping or boiling spices in vinegar. The aroma component of the spices gets extracted in vinegar and vinegary extract may be used in place of whole spice. It assists in maintaining the same taste and aroma and also standardizes the proportion of spices in the recipe. Nowadays, it is one of the most widely accepted methods of spice addition.

22.4.4.2 Sugar

Sugar is mainly used to adjust the sugar-to-acid ratio of the ketchup or sauce. Sugar may be added in the form of granular sugar, corn syrup and other syrups are used. However, granular sugar is most preferred one. About 1/3rd of sugar is added in the initial stage of boiling. This help in preserving the natural colour of the product. Rest of the sugar is added minute before final concentration is reached. Initial addition of sugar will adversely affect the colour of the product as cooking of the product with higher amount of sugar under acidic conditions flavour brown coloured “Furfural”, Commercial level, sugar level varies between 10-26%. Higher amount of sugar may impart higher sweetness which is not liked by consumers.

22.4.4.3 Common salt

Salt bleaches the colour of the tomato and also dissolve to some extent copper from the processing equipment. It is, therefore, desirable to add towards the end point of the process. Range of common salt varies between 1.5 – 3.5%, salt is added to enhance flavour of the product and exert preservative action to a lesser extent. Salt of very high purity is preferred for the ketchup manufacture. Salt also counteract the highly acidic flavour of the tomato pulp.

22.4.4.4 Vinegar

Well matured salt-vinegar, cider vinegar or malt vinegar may be used as acidulant in the product. However, these vinegars are not colourless; hence they may affect the colour of the finished product. Vinegar contains not less than 5 percent acetic acid. On industrial scale commercially available glacial acetic acid is preferred because of the following reasons.

- Lower

cost as compared to malt, or cider or salt vinegar

- Glacial

acetic acid is 100% acetic acid; hence it will have lesser effect of

heating.

Vinegar is always added towards the end of the process in ketchup or sauce manufacture. Since it is a volatile product most of the acid will lose during cooking. Ketchup contains 1.25-1.50 percent acetic acid. Vinegar contributes towards the flavour as well as microbial stability of the ketchup.

22.4.4.5 Thickening agent

Insufficient quantity of pectin in tomato juice, puree or paste invariably results in serum separation in ketchup during storage. Ketchup prepared by cold pulping process contains very less amount of pectin due to incomplete solubilization and extraction of pectin. Likewise using variety with low pectin content may also necessitate addition of certain thickening agents. Hence, pectin (0.1 – 0.2%), corn starch (1%) and other hydrocolloids may be added to control this problem. Xanthan gum is an ideal thickener for this type of products because of its acid stability and pseudoplastic flow properties it imparts. The glass or sheen, which xanthan gum imparts to these sauces or ketchup is another appealing factor for the consumer. Pectin may also be added @ 0.1-0.2 percent by weight of finished product in clear juice or pulp to check the problem of serum separation and to also increase viscosity.

Table 22.3 Recipe for tomato ketchup

|

S. No. |

Ingredient |

Amount |

|

1 |

Tomato pulp |

1 kg |

|

2 |

Sugar |

70 gm |

|

3 |

Salt |

10 gm |

|

4 |

Chopped onion |

1.5 gm |

|

5 |

Chopped garlic |

1.5 gm |

|

6 |

Red chili powder |

0.5 gm |

|

7 |

Cumin, Cardamom |

0.40 gm each |

|

8 |

Clove (headless) |

1.5 gm |

|

9 |

Cinnamon |

1.5 gm |

|

10 |

Vinegar |

10 ml |

22.4.5 Cooking & concentration

The tomatoes juice along with other ingredients is cooked and concentrated to get the desirable flavour, uniform taste and fine thickness or body. The cooking of ingredients may be carried out in open jacketed kettle or vacuum concentrator. The cooking continues till the concentration reached 25 percent TSS. However, concentration of 28-30 percent total solid is ideal as further increase may adversely affect the flavour of the product. However, to improve the stability of ketchup slightly higher amount of sugar, salt and vinegar is added.

22.4.6 Bottling & Packaging

The ketchup after attaining the desired total solid level and consistency is finally passed through a finisher to remove any tomato fibre, seeds and any other suspended solids. The Ketchup or sauce after cooking should be bottled hot at 85-88°C to prevent browning and loss of vitamin during subsequent storage and distribution. Hot filling of bottle also assist in creation of vacuum in the headspace during the cooling of ketchup. The crown cork used for ketchup bottle should be lined with polyvinyl chloride (PVC) to prevent the contact of ketchup with the metallic portion to avoid the “black neck” formation. However, nowadays sauce and ketchup is also packed in laminated flexible packaging materials consisted of polyethylene (PE), polyester (PET) and aluminum. These polymers may be co-extruded in different combinations to get the desired functional and mechanical properties. Sauce and ketchup require protection from oxidation and moisture migration/ingress. Moreover, certain squeezable bottles are also used for the packaging of these products. Bottled and packaged products are stored under ambient temperature (30-35°C) under dry places.

22.4.7 Pasteurization

Although, hot filling of the ketchup in bottle is considered safe for consumption and have sufficient shelf-life, but still come manufacturers prefer further thermal treatment. The hot filled bottles are pasteurized in hot water (85-88°C) for 30-35 minutes. Care must be taken to cool the bottle immediately after pasteurization to avoid the degradation of nutrients and over-processing. Shelf-life is also enhanced by using preservatives.

22.5 Defects in Ketchup

The two most common observed defects in ketchup are: serum separation and blackening specially around the neck. The latter defect is referred as “Black neck defect”. The tannins present in spices get extracted into the ketchup and when these phenolic compounds come in contact with iron leached out either from processing vessels or from the closure of ketchup bottles, they form ferrous tannate. This compound undergoes oxidation and form ferric tannate and it is a black coloured compound. To check it one should not use iron or copper utensils and headless clove should be used. The inner lining of bottle cap should be of PVC. Problem of serum separation as already been discussed in Section 2.4.5. Among the microbiological problem mold growth is the most serious one. Microbial growth can be taken care by adding chemical preservatives specially benzoic acid. Benzoic acid is added in the form of its sodium or potassium salt because of almost 54 times higher solubility of salt as compared to benzoic acid. As per FSSA guidelines the maximum permissible limit of benzoic acid is 750 ppm.

Fig. 22.5 Black neck defect in tomato

ketchup