Module 7. Beverages

Lesson 27

FRUIT BEVERAGES AND DRINKS

27.1

Introduction

Fruit beverages and drinks are one of the popular categories of beverages that are consumed across the globe. The fruit beverages and drinks are easily digestible, highly refreshing, thirst quenching, appetizing and nutritionally far superior to most of the synthetic and aerated drinks. In recent past the consumption of fruit based beverages and drinks has increased at a fast rate. Fruit juices or pulp used for the preparation of these products are subjected to minimal processing operations like filteration, clarification and pasteurization. The fruit juice or pulp, are mixed with ingredients like sugar, acid, stabilizers, micronutrients and preservative to develop beverages and drinks. There are various categories of fruit juice or pulp based beverages and drinks which are listed below.

Natural fruit juices, sweetened juices, ready-to-serve beverages, nectar, cordial, squash, crush, syrup, fruit juice concentrate and fruit juice powder belong to the category of non-alcoholic and non-carbonated beverages. The principle groups of fruit beverages are as follows:

· Ready-to-Serve (RTS) pre-packaged Beverages

· Fruit juice and Nectars

· Dilutable beverages

27.2 Ready-to-Serve (RTS) Beverages

The ready-to-serve beverages as per FSSA specifications should contain at least 10 percent fruit content and not less than 10 percent TSS besides 0.3% acid maximum as citric acid. The levels of permitted preservatives include 70 ppm (maximum) for sulphur dioxide and 120 ppm (maximum) for benzoic acid. The total plate count and yeast and mold counts should not exceed, to 50.0 cfu/ml and 2.0 cfu/ml, respectively. The Coliform counts should be nil in 100 ml beverage samples.

Since these beverages are consumed as such without dilution, hence are termed as “Ready-to-serve” beverage. The majority of packaged fruit beverages belong to this category. Wide range of fruits including mango, citrus fruits, berries, litchi, guava, pineapple, grapes etc. are preferred for RTS beverages. Required amount of sugar, acid, stabilizer, colouring and flavouring ingredients are added in juice or pulp along with water and the mixture is blending properly, filtered if desired. The RTS mix is pasteurized (80-90°C) in bottle (20-30 min), continuous juice pasteurizer (few seconds to one minute) and cooled immediately. Nowadays, UHT processing of RTS beverages is quite popular because of longer shelf-life and less loss of nutrients during processing.

The amount of fruit juice or pulp may vary according to fruit and cost effectiveness. The presence of oxygen in headspace often leads to oxidation resulting in off-flavour and loss of nutritive value, hence anti-oxidants such as ascorbic acid is often added in RTS beverages. Besides it, colour and flavour ingredients which are stable to heat and oxygen are preferred.

27.2.1 Natural fruit juice

Natural fruit juices also falls in the category of RTS beverage. It may be defined as pure juice which is extracted from ripe and mature fruits and contain 100 percent fruit content. The juice is extracted by various methods and contains mainly sugars, acids, vitamins, minerals and other minor components. These are preserved by thermal processing and freezing. The commonly available fruit juices are apple, pineapple, citrus, grapes, pomegranate and mango.

The sweetened juices are beverages which possess at least 85 percent juice and 10 percent TSS. The sugar and acids are added to increase the TSS content and also to balance the acid-to-sugar ratio. A wide variety of fruit juices are used for the purpose. Sometime two or more juices are mixed to develop a palatable and refreshing drink with better flavour and balanced nutrition. Such beverages are also called as “fruit punch”. In certain fruits the blending or mixing of juices is done to balance the acidity and minimize the flavor changes. Use of fruit juice concentrate with suitable dilution with water is mostly used on commercial scale to produce uniform quality product.

Example:

· Very sweet (grape) and very bitter (grapefruit)

· Highly acidic (lime, lemon, sour cherry) with bland tasting fruits (pear, apple)

· Highly flavoured (guava, banana) with bland & insipid tasting fruits (pear, loquat)

The freshly squeezed juices have very short shelf-life; hence they have to be stored at 0-5°C to check spoilage. Some of them may have low pH (below 4.5) hence they require thermal processing in the range of 85-95°C for a minimal period to ensure commercial sterility. The minimum TSS and acidity for various natural fruit juices has been specified by FSSA.

27.3 Nectar

Nectar is prepared from the tropical fruits pulp such as mango, litchi, guava, papaya, citrus fruits and pineapple by adding sugar, acid and other ingredients. As per FSSA specifications nectar should contain TSS not less than 15o Brix and not less than 20 per cent fruit content, except for pineapple and citrus fruits where fruit content should not be less than 40 percent. Fruit pulp or puree or juice or concentrate may be used as starting material. The acidity of the nectar should not be more than 3.5 per cent as anhydrous citric acid. The maximum permissible limit of preservative in nectar is sorbic acid at 50 ppm. The sorbic acid is added as sodium or potassium salt of sorbic acid. Nectar is also not diluted before consumption. Nectar is also characterized by cloudy appearance and thick mouthfeel. The cloudiness in nectar and other beverages is because of the presence of polysaccharides such as pectin, cellulose, hemicellulose and starch. The loss of cloudiness specially in citrus juices is due to the activity of pectin methyl esterase (PME), which cause de-esterification of pectin molecule resulting in settling down of pectin and loss of cloudiness. Therefore, citrus juices or comminutes must be thermally treated to inactive the PME. Sometime hydrocolloids are added to stabilize the cloudiness. Preservation of nectar is achieved in similar way as mentioned for RTS beverages.

The limited shelf-life of nectar (few days at refrigeration temperature) could be overcome by following any of the desired processing operation.

27.3.1 Flash pasteurization

The nectar may be pasteurized in plate type pasteurizer which is provided with heat recovery and cooling unit. Temperature in the range of 85-95°C for 15 to 60 seconds is used for most of the products; however it again depends on type of the juice and initial microbial load. The products where both enzyme and microbial inactivation is desired slightly higher temperature i.e. 90-95°C for not more than 15 seconds is used. Tubular pasteurizer is preferred for slightly viscous nectars. For aseptic packaging operations, pasteurizer is integrated with aseptic packaging unit either directly or via an aseptic buffer tank.

27.3.2 In-pack pasteurization

In-pack pasteurization is most preferred methods on small scale units. The juice is filled in packs, mainly bottles and immersed in heated water tanks which are held at 80-90°C. The pasteurization conditions are 80-85°C for up to 20 minutes to ensure safety of the product. The treated bottles are air-dried and then labeled. Care must be taken to ensure that pack is sealed properly and product is processed at intended temperature.

27.3.3 Hot fill operation

Hot filling offer a simpler mean of ensuring microbial integrity of the nectars. The bulk product is heated to a pre-determined temperature then filled hot (70-85°C) in packs and sealed immediately. In case of glass bottle they should be pre-heated to minimize thermal shock. The packs are inverted for proper mixing of the nectar and held at desired temperature for required time. Finally they are cooled in hydro-cooler to 25°C, surface is air-dried and labeled.

27.4 Dilutable Beverages

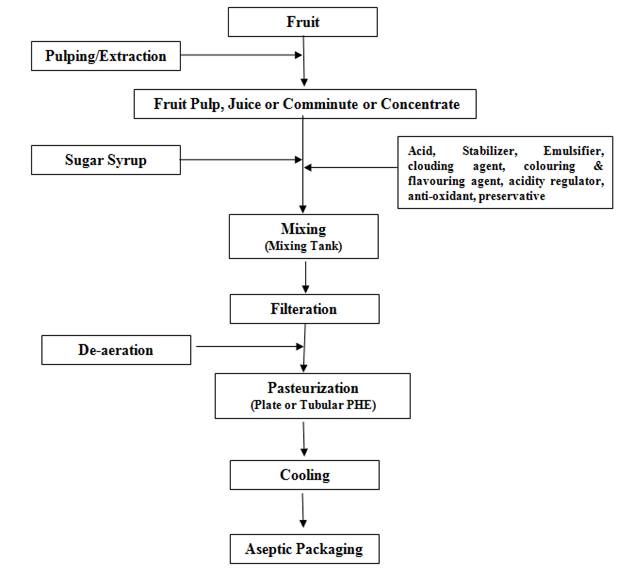

Dilutable beverages are the one which are consumed after mixing with suitable diluents like water, alcoholic drinks or milk. The process for making such beverages is quite similar to the syrup manufacture meant for carbonated beverages. These products offer a number of advantages including the ability to use different syrup to water ratio, reduction in bulk, utilization of surplus and bland tasting fruits and offer novel innovations in formulations. The various ingredients and their role in manufacturing of dilutable beverages are listed in Table-27.1. The process diagram for the manufacture of dilutable beverages is outlined in Figure 27.1.

Table 27.1 Ingredients used in dilutable beverages

|

S. No. |

Ingredient |

Remark |

|

1 |

Fruit Components |

Added in the form of fruit juice or pulp or comminute (whole fruit preparation), required amount should be more than 25%. For uniformity concentrated fruit juice or pulp or comminute of standard degree brix is used. Source of fruit sugar, acid, pectin, colouring pigments, flavouring compounds and micronutrients. |

|

2 |

Syrup |

Carbohydrate syrup is added in various forms like sucrose, invert syrup, glucose syrup or modified syrup. Provide body, impart sweetness; assist in development of flavour, mild preservative effect. Always added after filtration and sterization. |

|

3 |

Acid |

Citric acid is most preferred acidulant, other that may be used are malic, lactic and tartaric. Balance acid to sugar ratio, anti-microbial. Impart flavour as well. |

|

4 |

Preservatives |

Mainly added to prevent growth of fungi, yeast, lactic acid bacteria. Permitted are sulphur dioxide, benzoic acid and sorbic acid. |

|

5 |

Flavourings |

Mostly natural or natural identical flavourings are used. Must improve the flavour of beverages without affecting other properties. |

|

6 |

Colourings |

A permitted food colour that may enhance the aesthetic appeal of the beverage is used. It may include natural, natural identical or synthetic dyes. Maximum permissible limit is 100 ppm for coal tar dyes. |

|

7 |

Other Additives |

It may include stabilizers to keep the fruit solids in suspension and improve mouthfeel of the beverage. Acidity regulators, emulsifiers, anti-oxidants and clouding agents are also used to enhance the acceptability of these beverages. |

Fig. 27.1 Process flow diagram for the manufacture of dilutable beverages

Two major products fall into the category of Dilutable beverages are discussed hereunder.

27.4.1 Cordial

Fruit juice cordial is a sparkling clear sweetened fruit beverage from which all the pulp and other suspended materials have been completely eliminated. Cordial is prepared by mixing clarified fruit juice, with sugar syrup, acid and other ingredients. As per FSSA specification, cordial should contain not less than 25 percent fruit content and the TSS content should not be less than 30° Brix .The acidity of the cordial should not be more than 3.5 per cent as anhydrous citric acid. The maximum permissible limit of preservative in cordial is 350 ppm of sulphur dioxide or 600 ppm of benzoic acid. The citrus juices such as lime and lemon are preferred for making cordial. The cordial are generally consumed by mixing with alcoholic beverages like gin.

The fruit juices are either stored for longer period to remove suspended solids and pectinous materials or it may be treated with commercial enzyme preparations like pectinase to hydrolyze pectin. The clarified juice is used for cordial preparation.

27.4.2 Squashes and crushes

Squash is the product, which is prepared by mixing of calculated quantity of fruit juice or pulp, with sugar, acid and other ingredients. As per FSSA specifications, squash should contain not less than 25 per cent fruit content in finished product and the total soluble solids content should not be less than 40° Brix. The acidity of the squash should not be more than 3.5 per cent as anhydrous citric acid. Mango, orange, lemon, pineapples, grape and litchi are used for making squash commercially. Squash can also be prepared from lemon, bael, guava, pear, apricot, muskmelon, papaya, passion fruit, peach, plum, mulberry, raspberry, strawberry, grapefruit, etc. The maximum permissible limit of preservative in squash is 350 ppm of sulphur dioxide or 600 ppm of benzoic acid. Potassium metabisulphite is not added in dark coloured fruits as it may bleach the anthocyanin pigments. In such beverages sodium benzoate is used.

Commercially available squash contain 40 to 50 percent sugar and around 1.0 percent acid. They are diluted in the ratio of 1:4 before consumption. There is another category of dilutable beverage called crush. As per FSSA guidelines, crush must contain not less than 25 percent fruit content and 55 percent TSS. Mostly, the comminutes of citrus fruits and pineapple are used for crush manufacture.

Syrup is a type of fruit beverage that contains at least 25 percent fruit juice or pulp and not less than 65 percent TSS. It also contains 1.25-1.5 percent acid and diluted before consumption. The syrups from rose petals, almond, mint, khus, sandal and kewra are quite popular.