Module 8. Tea

Lesson 30

SPECIALTY TEA PRODUCTS

30.1 Introduction

Value addition to tea has been a reality and since people are fond of stimulating beverages, there has been introduction of an array of specialty tea products. Some of the examples of such specialty tea products are discussed herein.

30.2 Flavoured Tea

Teas are sometimes scented with various plant essential oils such as lemon, bergamot, rose and fragrant olive which impart sweet floral attributes to enhance the natural flavour of tea.

Other teas are blended with flower petals, spices or dried leaf such as Rosemary, Peppermint, Camomile and Chrysanthemum.

30.2.1 Flavours

The flavours that have been used include chocolate, jasmine, mandarin orange peel, Bergamot and other sweet herbs. In India, cardamom, ginger, lemon, bergamot and mint are popular flavoured teas.

30.3 Brick Tea

These are tea (black or green) which are compressed in the form of bricks or cakes. Portions of bricks are broken off for use and are sometimes cooked with butter or other fats.

30.4 Herbal Tea

This type of tea can be made using dried rosemary herb. Prepare dark out of optimum level of concentration of Rosemary herb. Blend black tea and rosemary; combination of other herbs like basil, mint, lemongrass, thyme, chamomile with rosemary.

30.5 Tea Bag

The first tea bags were hand-sewn silk bags and tea bag patents dated as early as 1903. First appearing commercially around 1904, tea bags were successfully marketed by the tea and coffee shop merchant Thomas Sullivan from New York, who shipped his tea bags around the world. Modern tea bags are usually made of paper fibre. The heat-sealed paper fiber tea bag was invented by William Hermanson, one of the founders of Technical Papers Corporation of Boston. The rectangular tea bag was invented in 1944. Prior to this tea bags resembled small sacks.

The tea bag is referred to as ‘Cinderella’ of tea industry – now dressed in paper instead of silken gown.

A tea bag is a small, porous sealed bag containing tea leaves and used for brewing tea. Tea bags are commonly made of paper, silk or plastic. The bag contains the tea leaves while the tea is brewed, making it easier to dispose of the leaves, and performs the same function as a tea infuser. Some tea bags have an attached piece of string with a paper label at the top that assists in removing the bag while also identifying the variety of tea.

A broad variety of teas, including herbal teas, are available in tea bags. Typically, tea bags use fannings, the left-overs after larger leaf pieces are gathered for sale as loose tea, but some companies such as Honest Tea sells teabags containing whole-leaf tea.

30.6 Products Promoted on Health Grounds

30.6.1 Decaffeinated tea

This type of tea is promoted on health grounds. Chloroform or methylene chloride is an effective solvent for isolating caffeine from tea leaf. However, it is not widely accepted by consumers because of its toxicity. Decaffeination using supercritical carbon dioxide is effective and leaves no solvent residues, but it needs expensive equipment. Sawdust lingo-cellulose columns can be used to separate caffeine from tea extracts, but they are difficult to use for decaffeination of tea leaf.

30.6.1.1 Hot water treatment – an alternate safe method

When fresh tea leaf was decaffeinated with a ratio of tea leaf to water of 1:20 (w/v) at 100°C for 3 min, caffeine concentration was decreased from 23.7 to 4.0 mg/g, while total tea catechins decreased from 134.5 to 127.6 mg/g; 83% of caffeine was removed and 95% of total catechins was retained in the decaffeinated leaf. Hence, hot water treatment can be considered to be a safe and inexpensive method for decaffeinating green tea. However, a large percentage of tea catechins were lost if rolled leaf and dry tea were decaffeinated by such treatment and so this process is not suitable for processing black tea.

30.7 Aseptic Packaging Tea Concentrates

These are produced from top quality tea leaf (Camellia sinensis) through hot water extraction and Reverse Osmosis (RO) concentration at low temperature. It is then subjected to Ultra High Temperature (UHT) treatment and aseptically packaged. The products include Green tea, Jasmine tea, Oolong tea and Black tea.

The liquid concentrates look crystal clear and retain the flavor characteristics of tea leaf and are ideally suitable for making iced tea mixes and Ready-to-Drink (RTD) tea beverage.

30.8 Instant Tea

It is the water soluble extract of tea leaf, usually marketed as a powder, flake or granule, either pure or as a part of flavoured mixes.

Most Instant tea is made from black tea, but some is made from green tea. These are produced especially in USA and UK. Iced lemon teas are popular example in USA.

Instant tea is presently manufactured by spray/freeze drying of the concentrated brew of processed tea leaves/dust. A new technique has been developed for the production of instant/soluble tea powder from the expressed juice of green leaves. After plucking, the leaves are crushed and juice pressed out. The juice is then subjected to fermentation under specified conditions. The fermented juice is steamed, centrifuged and freeze-dried to get instant tea powder. At the same time, the pressed leaf residue is subjected to fermentation and drying for preparation of tea granules. The instant tea produced is of good liquoring characteristics. The theaflavin to thearubigin ratio was 10.71 for instant tea and 12.12 for tea granules. The caffeine content was 40.4 mg and 96 mg per cup for instant tea and tea granules respectively. There is considerable savings in the economy as the juice and residue are converted into value-added products using this method.

30.8.1 Manufacturing process for instant tea

The processing in tea processing plant includes extraction, separation of waste, evaporation and spray drying. The plant size varies from 5 kg/h to 1000 kg/h of instant tea.

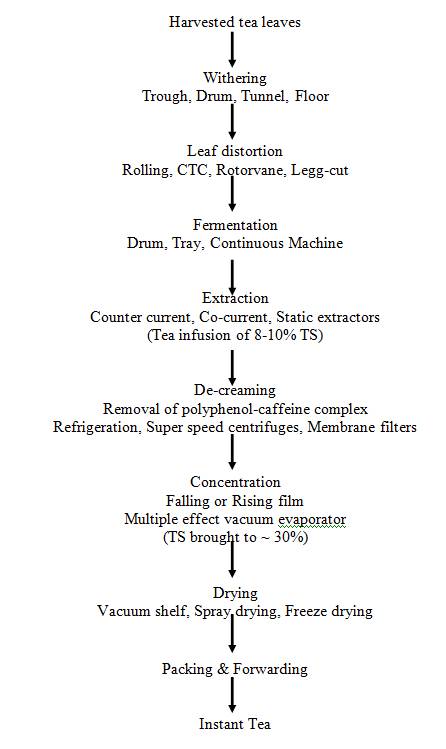

The processing steps are as outlined below:

· Instant tea is manufactured from black tea by extracting the brew from processed leaves, tea wastes or undried fermented leaves.

· The extract is concentrated under low pressure, and dried to a powder by any of the processes including freezing, drying, spray-drying and vacuum-drying.

· Low temperature is used to minimize the loss of flavor and aroma.

The flow chart for production of Instant tea is furnished in Fig. 30.1.

Fig. 30.1 Process flow-chart for production of Instant Tea

30.9 Recent advances in tea industry

In recent past, products like value added tea, Ready-to-drink or Instant type or complete tea powder. A leading tea manufacturer developed ‘Chicory tea’ comprising of 70% tea, 20% chicory and 10% tapioca. In USA, the non-conventional tea products include instant tea, flavoured tea, decaffeinated tea, tea beverage (RTS), carbonated tea, liquid tea concentrates, tea mixes. Vacuum packed teas can retain freshness better.