Module 2. Cereal processing

Lesson 7

BARLEY:

CLASSIFICATION, MALTING AND PROCESSING

7.1 Introduction

Barley (Hordeum vulgare L.), a major world crop ranks among the top 10 crops and is fourth among the cereals. Barley contributes significantly to the world’s food supply as human food, malt products, and livestock feed. However, the barley crop may be considered relatively under–utilized with regard to its potential use as an ingredient in processed human foods. Barley belongs to the genus Hordeum and can be considered one of the most ancient crops.

7.2 Barley Classification

Barley is a grass belonging to the family Poaceae, the tribe Triticeae. The chief taxonomic characteristic of Hordeum is its one–flowed spikelet. Three spikelets alternate on opposite sides at each node of the flat rachis of the spike or head. Thus is formed a triplet of spikelets at each node–the central and the two laterals. Each spikelet is subtended by two glumes. When all three spikelets are fertile, the spike is described as six–rowed. When only the central spikelet is fertile, the spike is two–rowed.

Most barleys grown for commerce are husked, that is the palea and lemma of the floret adhere to the outside of the grain. Huskless barley are not suitable for malting, but they are used for human foods as their digestibility is higher than the hulled type.

7.3 Chemical Composition of Barley Grain and Malt

Carbohydrates constitute about 80% by weight of barley grain. Starch is the most abundant single component, accounting for up to 65%, but polysaccharides of cell wall origin are also quantitatively important and may represent more than 10% of grain weight. Barley malt is produced by controlled steeping and germination schedule. The gross chemical changes observed during malting are the net result of degradation of reserve substances. The chemical composition of barley grain and malt is given in Table 7.1.

Table 7.1 The Chemical composition of barley and malt

|

Component |

Proportions (Dry Weight, %) Barley Malt |

|

|

Starch |

63 – 65 |

58 – 60 |

|

Sucrose |

1 – 2 |

3 – 5 |

|

Other sugars |

1 |

2 |

|

Water– soluble polysaccharide |

1 – 1.5 |

2 – 4 |

|

Alkali– soluble polysaccharide |

8 – 10 |

6 – 8 |

|

Cellulose |

4 – 5 |

5 |

|

Lipids |

2 – 3 |

2 – 3 |

|

Proteins |

10 – 12 |

8 – 11 |

|

Albumins and globulins |

3.5 |

2 |

|

Hordeins |

3 – 4 |

2 |

|

Glutelins |

3 – 4 |

3 – 4 |

|

Nucleic acids |

0.2 – 0.3 |

0.2 – 0.3 |

|

Minerals |

2 |

2.2 |

|

Others |

5 – 6 |

6 – 7 |

7.4 Processing of Barley

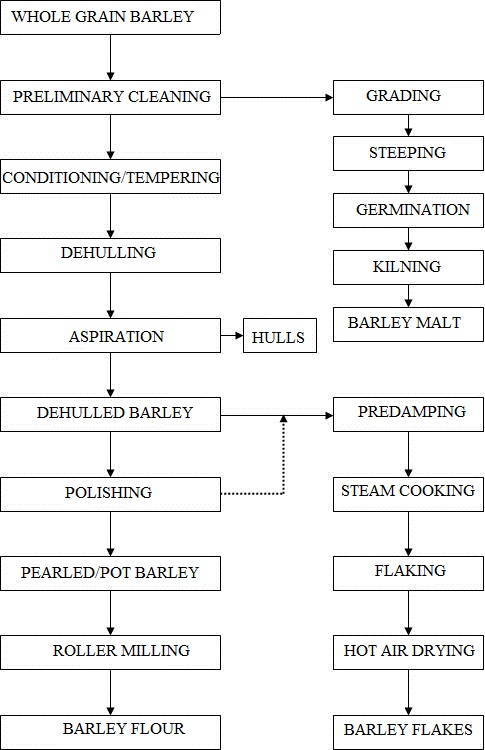

Barley is often milled to obtain blocked barley, pearled barley, barley groats, barley flakes and barley flour for human consumption. The sequence of operations in barley milling may be as follows: preliminary cleaning, conditioning or tempering, bleaching (blue aleurone barley), blocking or shelling, aspiration, size grading by sifting, groat cutting, pearling of blocked barley or large barley groats, grading and sifting and polishing. Some of the commercially available barley products are described below.

1.

Pot

and pearled barley

are prepared by gradual removal of hull, bran and germ by abrasive action in a

stone mill. Production of pot barley is the first stage of pearling, which may

remove 7 – 14% of the weight of the grain. Further abrasion results in the

removal of seed coat (testa and pericarp), aleurone, subaleurone layers and the

germ leaving behind a central endosperm rich in carbohydrates and proteins.

2.

Barley

flour is made

by roller–milling of pearled or blocked barley.

3.

Barley

flakes are made

by predamping of barley groat, steam cooking of groats or pearled barley,

flaking and hot air drying of flakes.

4.

Barley

bran (excluding

the hulls) consists of testa and pericarp, germ, the tricellular aleurone and

subaleurone layers. Barley bran is obtained as a by–product during barley

milling process.

Fig. 7.1 Flow diagram of barley processing

7.5 Malting of Barley

In the production of malt based beverages and malted milk food, barley grain is first converted into malt. The malting process commence with the steeping of barley in water at a temperature of about 12°C for 36 hours with frequent aeration, to achieve a moisture level sufficient to activate metabolism in the embryonic and aleurone tissues, leading in turn to the development of hydrolytic enzymes. The wet barley is germinated around 14°C for a period of about 144 hours. During germination, enzymes migrate through the starchy endosperm, progressing from the embryo end of the kernel to the distal end. In this mobilization phase, generally referred as “modification”, the cell wall and protein matrix of the starchy endosperm are degraded, exposing the starch granules. After a period of germination, the “green malt” is kilned at a temperature not exceeding 85°C, to arrest germination and stabilize the malt by lowering the moisture levels, typically to less than 5%. In the process, undesirable raw flavours are removed and pleasant “malty” notes are introduced. The kilning process is also responsible for developing the colour of the malt.

7.5.1 Biochemistry and chemistry of malting

Essentially, malting allows the optimal development of hydrolytic enzymes by the aleurone cells of barley and controlled action of these enzymes to eliminate structural impediments to subsequent easy and complete extraction during mashing. Elucidation of the part played by gibberilic acid in stimulating secretion of a–amylase, endopeptidase, endo–b–glucanases and inorganic ions from the aleurone to the central endosperm has encouraged the development of malting modifications.

7.5.2 Steeping

In many respect, the steeping operation is the most critical stage in malting. To produce homogeneous malt, it is necessary to achieve even moisture content across the grain bed. Most barley requires a steeping regime that takes them to 42 – 46% moisture. At the commencement of steeping, the embryo and husk absorb water far more rapidly than does the starchy endosperm. Besides water, barley requires a supply of oxygen to support respiration. Oxygen access is inhibited if the grain is submerged in water for prolonged periods, a phenomenon that dictates use in modern malting regime of steeps interrupted by air rest periods. Additionally the steep water may be aerated or oxygenated. Air rests serve the added role of removing carbon dioxide and ethanol, which are the products of respiratory metabolism and may inhibit germination. A typical steeping regime may involve an initial steep to 32 – 38% moisture, an air rest of 10 – 20 h, followed by a second steep to raise moisture to 40 – 42%. The entire steeping operation in the modern malting plants is likely to cover 48–52 h.

7.5.3 Germination

Germination is generally targeted to generate the maximum available extractable material by promoting endosperm modification through the development, distribution and action of enzymes. Enzyme synthesis occurs during germination in the aleurone and subsequently migrates into the endosperm to effect hydrolysis. During hydrolysis enzyme development follow the sequence: cell wall degrading enzymes, proteases, and then amylases. The process is controlled by maintaining moisture levels within the grain, supplying oxygen, removing carbon dioxide, and eliminating excess heat formed by respiration. Temperature is controlled throughout the germination period, typically in the range of 16 – 20°C. Modification of the barley commences at the proximal end of the grain, adjacent to the scutellum as shown in Fig. 7.1.

The rate of modification depends on: (1) the rate at which moisture distributes through the starchy endosperm, (2) the rate of synthesis of hydrolytic enzymes, (3) the extent of release of these enzymes into the starchy endosperm, and (4) structural features of the starchy endosperm that determine its resistance to digestion.

7.5.4 Kilning

Through the controlled drying of green malt, the maltster is able to: (1) arrest modification and render malt stable for storage, (2) ensure survival of enzymes, where appropriate, for subsequent employment in processing, and (3) introduce desire colour and flavour characteristics. Kiln drying is divided into four major phases: (1) free drying down to approximately 23% moisture, (2) an intermediate stage, to 12% moisture, (3) the bound water stage, from 12 to 6% moisture, and (4) curing, in which the moisture is typically taken to 2–3%. Principle changes occurring during kilning is the browning or Maillard reaction. The interaction of reducing sugar and amino acids produces reductones, which in turn can be converted by polymerization to the colourful melanoidins or, by alternative routes, to the heterocyclic pyrazines, thiophenes, pyrrolles, and furans. The oxygen heterocyclics are responsible for toffee or caramel flavours. The pyrazines impart the roasted, coffee like flavours.