Module 2. Cereal processing

Lesson 8

MILLETS: TYPES AND

PROCESSING

8.1 Introduction

The grasses known collectively as millets are a set of highly variable, small seeded plant species indigenous to many areas of the world. Millets are of value especially in semiarid regions because of their short growing season and higher productivity under heat and drought conditions. Pearl millet is the most widely grown millet and is a very important crop in India and parts of Africa. Finger millet is popular in East Africa and India. Foxtail and Proso millets are cultivated primarily in the Near East and China. Proso millet is also widely cultivated in the Russia Federation. Fonio and teff are grown in West Africa and Ethiopia, respectively. Most commonly grown millets with their common name is listed in Table 8.1. The millets originated primarily in East and West Africa, Eurasia, India and China from wild seed stock. Pear millet is one of the earliest domesticated millets; carbonized grains have been found in sub-Saharan and West African sites inhabited 4000-5000 years ago.

8.2 Structural and Physical Properties

Kernel characteristics of the various millets are extremely diverse. The millets can be divided into two types of seeds: utricles and caryopses. In the utricle, the pericarp surrounds the seed like a sac but is attached to the seed at only one point. Finger millet, proso and foxtail millets are utricles. In these millets, the pericarp usually breaks away from the seed coat or testa, which is well developed, thick and forms a strong barrier over the endosperm. In a caryopsis, the pericarp is completely fused to the seeds. Pearl millet, fonio and teff are caryopses. For pearl millet, the kernels are composed of the pericarp, endosperm and germ, which comprise 8.4, 75.1 and 16.5% of the total kernel weight, respectively.

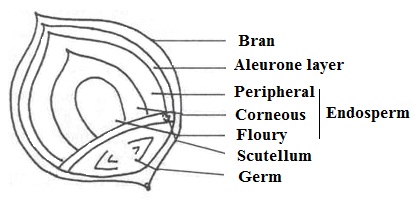

The endosperm comprises the majority of the kernel weight for all millets. There are four structural parts of the endosperm: the aleurone layer and the peripheral, corneous and floury endosperm areas (Fig. 8.1). All millets have a single layer aleurone that completely encircles the endosperm. The aleurone cells are rectangular with thick cell walls, and they contain protein, oil, minerals and enzymes. The peripheral corneous and floury endosperm areas are beneath the aleurone, in that order.

Fig. 8.1 Structure of millet

8.3 Composition of millets

The mean values and variations in proximate composition of differnet types of millets are presented in Table 8.2.

Table 8.1 Common and scientific name of major types of millets

|

Scientific Name |

Common Name |

Growing Areas |

|

Pennisetum glaucum P. americanum P. typhoiidesPanicum milaceum |

Pearl millet |

Africa, India |

|

Eleusine coracana |

Finger millet |

Africa, India, China |

|

Setaria italica |

Foxtail millet |

China, Near East, Europe |

|

Digitaria exilis D. iburua |

Fonio |

West and North Africa |

|

Panicum sumatrense P. psilopdium |

Little millet |

India, Nepal, Burma |

|

Eragrostis tef E. abyssinica |

Teff |

East Africa, Ethiopia |

|

Paspalum scrobiculatum P. commersoni |

Kodo millet |

Southern Asia |

|

Echinochloa crusgalli E. utilis E.frumentacea E. colona |

Japanese milllet |

Asia |

Table 8.2 Proximate composition of millets

|

Millet |

Protein(%) |

Fat, Ether extract (%) |

Crude fiber (%) |

Ash (%) |

NFE (%) |

Starch (%) |

|

Pearl millet |

14.5 |

5.1 |

2.0 |

2.0 |

76.4 |

71.6 |

|

Finger millet |

8.0 |

1.5 |

3.0 |

3.0 |

84.5 |

59.0 |

|

Proso |

13.4 |

9.7 |

6.3 |

4.2 |

69.4 |

57.1 |

|

Japanese millet |

11.8 |

4.9 |

14.3 |

4.9 |

64.1 |

60.3 |

|

Foxtail millet |

11.7 |

3.9 |

7.0 |

3.0 |

74.2 |

55.1 |

|

Kodo |

10.4 |

3.7 |

9.7 |

3.6 |

72.6 |

72.0 |

|

Tef |

10.9 |

2.4 |

2.4 |

2.2 |

82.1 |

73.1 |

|

Fonio |

8.7 |

2.8 |

8.0 |

3.8 |

76.7 |

61.0 |

All values are expressed on dry matter basis.

Protein conversion factor=N X 6.25.

NFE=Nitrogen-free extract.

8.4 Food Utilization

Millets have been utilized for human food for prehistoric times. In India, virtually all of the pearl millet and most of the finger millet is directly consumed as human food. The most important use of pearl millet grain is in baking chapattis or rotis. Millet grain is also used for production of rice-like products and porridges. Pearl millet is also used to produce malt and alcoholic beverages. Millet flour has been successfully incorporated into cutlets, pakoras, weaning foods and biscuits.

8.5 Postharvest Processing

8.5.1 Storage

Millets are harvested, dried and stored intact in storage bins. Usually, the millet heads are pounded in a mortar and pestle, winnowed and the grains required for daily consumption is further processed (dehulled and ground) in the mortar and pestle as needed. Millets are traditionally stored in clay pots or raised huts. Millets have reputation of being less susceptible to the insect attack than other grains. This is due to small size of millet grains. The another reason is that they are commonly grown in semi arid areas of the world where the relative humidity is typically less than 40%, which is not optimum for many pests.

8.5.2 Milling

Milling separates the grain into three components, germ, endosperm and seed coat. Milling techniques practiced mostly depend on the end-use. Milling process starts with the cleaning of the grains, to remove unwanted impurities and broken grains, using vibratory sieves, aspirators and specific gravity separators. The cleaned grains are conditioned, by addition of water, to soften the endosperm. In developing countries, millets are normally decorticated and ground with mortar and pestle prior to use. Grinding stones are also used, followed by winnowing or washing at various stages of grinding to remove bran, coarse particles and fine particles. These milling techniques are labour intensive. In India, stone hand grinder, consisting of two round stones rotating horizontally against each other is used for grinding millets. Millets are also decorticated with abrasive discs in mechanical huller and ground into flour with attrition or hammer mills.

The endosperm is recovered in the form of grits, with the minimum production of flour. Yields of various fractions from the milling process are grit, 76.7; bran, 1.2; germ, 11; fiber, 10%.