Module 3.

Bakery and snack foods

Lesson 12

TECHNOLOGY OF BISCUIT MAKING

12.1 Introduction

Baking industry is the most stable sector in the food manufacturing industries. The principal basis for most products in this range is wheat flour. Addition of water and various other ingredients give us variety of products like cookies, crackers, cakes, pastries and biscuits. Biscuits are flat, crisp, baked good, whereas cookies are softer and thicker. Cracker means biscuits of a low sugar and fat content, frequently bland or savory. These types of flour confections are palatable, easy to carry and don’t require further preparation before consumption and thus they are considered as staple snacks.

12.2 Product Characteristics

Biscuit is a low moisture bakery product. Moisture content of biscuit is typically below 4% depending upon its weight, thickness and shape. Biscuit dough can be made from soft wheat flour with a high amount of sugar (25-55%) and shortening (20-60%). They are classified based on the way the dough is placed on the baking band e.g. rotary molded, wire-cut, cutting machine, etc.

12.3 Ingredients

12.3.1 Flour

Soft wheat flour is the main component in most recipes. Wheat flour consists of 65 – 75% starch and 7- 16% protein. When water is added, during the makeup of dough, starch absorbs a significant amount of water and may act as filler in the continuous protein network with the proteins. During baking, starch granules get gelatinized, which is a major part of the dough. Cookies, crackers flours are normally not treated with additives. For cookies to be premium quality, soft wheat flour containing 8 to 10% protein and less than 0.4% ash content is ideally suited.

12.3.2 Water

Water affects textural properties of baked products. Water acts as a plasticizer, and the amount of water used is adjusted to produce a batter or dough of acceptable consistency for processing. Water is needed for hydrating the proteins, gelatinizing the starch, making leavening agent function, activating the enzymes, dissolving sugar and salt, as well as acting as major heat transfer mechanism during baking through evaporation and condensation.

12.3.3 Fat

Fat provides shortness character to the products, like soft, pleasant and crumbly texture. Fats and oils are used in dough and batters, in surface sprays and in cream fillings and coatings such as chocolates. Bakery fats are often premixed with or used in conjunction with emulsifiers. The function of emulsifier is to promote formation and stabilization of water/fat/air emulsions.

12.3.4 Sugar

Sugar is most important ingredient after flour in soft wheat products such as biscuits, cookies, cakes, etc. Apart from providing sweetness to the product, sweeteners provide one or more of the following functions: tenderizing, texture, yeast nutrient and fermentation control, stabilizing, bulking agent, humactancy, flavour, crust colour and shelf-life extension. Sucrose, corn syrup solids, invert sugar, honey, glucose syrup and certain permitted intense sweeteners are used in manufacture of soft wheat products.

12.3.5 Salt

Salt is added to dough as a seasoning or as flavour enhancer. Salt also inhibits yeast growth and thus help in controlling the fermentation.

12.3.6 Other ingredients

- Various other ingredients are

used in the manufacture of biscuits such as leavening agents, emulsifiers,

chocolates, egg products, dairy products, fat replacers, spices, flavours,

colours, icing, etc.

- Baking powder is widely used

for leavening of the cookies and biscuits mixture. It controls the spread

and imparts lightness to the product. Excess use of sodium bicarbonate

(baking soda) than recommended may impart alkaline flavour to the end

product. Ammonium bicarbonate should be used in products which are quite

dry after baking, otherwise ammonium odour will

be retained if the product is moist. Baking soda is combination of sodium

bicarbonate and an acid salt. During baking, in presence of moisture, gas

will evolve which helps in leavening of product.

- Baking powder are of three

kinds:

1.

Fast

acting: Most of

the CO2 is released during bench operations and very little gas is

released during baking.

2.

Slow

acting: All the

gas is released during baking.

3.

Double

acting: This is most

widely used baking powder by the bakers. This type of baking soda releases part

of gas during bench operations and part of the gas during baking.

- Milk solids have a binding

action on the flour proteins. When milk solids are used in large amount,

they cause less spread of the cookies and biscuits.

- Eggs, if added, give structure,

impart flavour and taste. If it is used in large amounts, it may result in

giving biscuits and cookies a rise rather than spread. Egg yolk produces a tender cookies than whole egg.

12.4 Technology of Crackers

- Crackers contain little or no

sugar and moderate levels of fat. They are usually made from strong flour

and developed dough. They generally contain 100 percent flour, 5-20 per

cent fat and 0-2 per cent sugar and low moisture content of 20-30 per cent

in the dough.

- There are three types of

crackers: saltine, chemically leavened (snack crackers) and savoury.

- Saltine crackers are produced

from fermented dough. They are made by a sponge (flour 65%, water 25% and

yeast 0.4%) and dough (Flour 35%, salt 11% and soda 0.45%) process. The

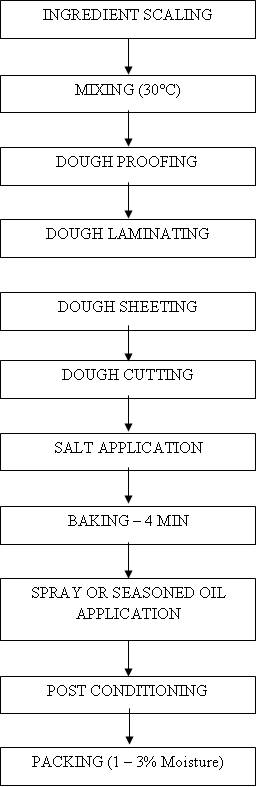

- Chemically leavened crackers

are not fermented. They do not contain yeast, but are leavened by chemical

baking leaveners. They contain more shortenings

and much higher level of flavouring materials. The dough is mixed once

with the ingredients, allowed to rest, sheeted and laminated, and cut and

docked. The texture of snack crackers is denser than that of saltine.

- Savoury crackers are also produced

from fermented dough. The intense savoury flavours are produced by adding the appropriate

flavouring agents directly to the dough or to the surface of crackers

after baking.

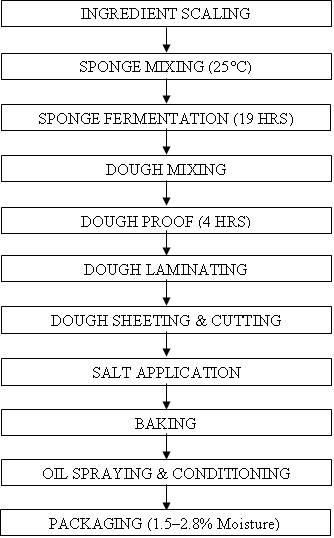

- Production flow chart for

saltine crackers and chemically leavened crackers are shown in Figure 12.1

and 12.2, respectively. Saltine crackers are distinguished by their long

fermentation time and they are particularly light and flaky in texture.

During fermentation process, the pH drops from 6.0 to about 4.0.

- As compared to saltine crackers,

chemically leavened crackers contain more shortening and much higher

levels of flavouring materials. They generally do not contain yeast and

are not given an extended fermentation period.

Fig. 12.1 Production flow chart for manufacture of saltine crackers

Fig. 12.2 Production flow chart for manufacture of chemically leavened crackers

12.5 Technology of Biscuits

· The name ‘cookie’ can be regarded as synonymous with biscuit but the cookies are more comprehensive in meaning in the USA and the latter in the UK. Groupings have been made in various ways based on

1. The method of forming dough and dough piece

· Fermented

· Developed

· Laminated

· Cut

· Moulded

· Extruded deposited

· Wire cut co-extruded

2. According to texture and hardness

· Biscuits

· Crackers

· Cookies

3. According to the recipe enrichments with ingredients like fat and sugar

· Another type of classification based on secondary processing are Cream sandwiched, chocolate coated, moulded in chocolate, iced (half coated with an icing that has been dried)and added jam or mallow (or both)

· The main raw materials for biscuits are flour, sugar and shortening. For protein enriched peanut flour or isolates, soy flour etc. can be added.

· Other ingredients include leavening agents, vitamins, minerals and flavours. In sweet biscuits, cane sugar is added while in salty biscuits, sodium chloride (0.5-1.0 percent is added).

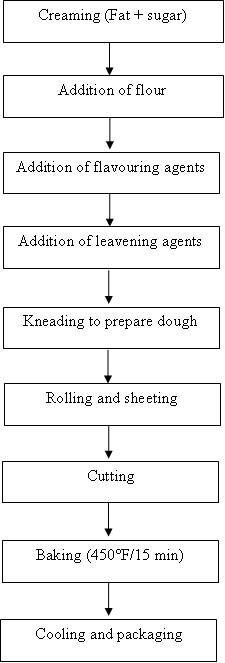

· The main steps involved in biscuit making are (Fig.12.3)

1. Mixing and kneading: Weighed amount of sifted flour, sugar, shortening and flavouring agents are mixed in mechanical mixer. Water and baking powder are added during mixing to obtain dough of desired consistency. Kneading for 10-20 min produces biscuits with fine structure, smooth crust and better appearance.

2. Sheeting and shaping: The dough is then rolled into sheets of desired thickness by passing it through pairs of rolls. The sheets are then cut by mechanically worked stamped dividers fitted with dies.

3. Baking and cooling: the cut biscuits are then transferred to plate sheet or wire mesh bands travelling through ovens. The biscuits are generally baked at 450°F for 15 min and cooled to ambient temperature after baking.

4. Packaging: the biscuits should be packed in moisture and grease proof cellophane or metalized laminated foils.

Fig. 12.3 Steps in involved in biscuit making