Module

4. Pulse processing

Lesson 15

METHODS OF PULSE MILLING – WET AND DRY

METHOD, DOMESTIC AND COMMERCIAL MILLING

15.1 Introduction

Pulses are defined as dried edible seeds of cultivated legumes. Pulses occupy important place in human diet. They serve as major sources of dietary protein and energy. The production of pulses in India was 13.19 million tones in 2001-02, which was 27% of the World’s production. Bengal gram/Chick pea (chana), pigeon pea (tur/arhar), cow pea (lobia), black gram (urad), green gram (moong), lentils (masur), peas (matar) are some of the major pulses grown in India.

Pulses are consumed in its dehusked and split form which is termed as dal. Pulse milling (dal milling) is accomplished in three major steps namely: loosening of husk, dehusking and splitting of pulses. Pulses are generally consumed in the form of Dal. Traditional methods for processing of pulses were labour intensive, time consuming and incurred losses. Modern technologies for processing of pulses have replaced old age methods and thus avoid losses and saves time. Processing of pulses involves two basic steps – (i) seed coat/husk loosening and its removal and (ii) conversion of seed grain into splits and grinding into flour depending upon its end-use. Various methods are employed for pulse/dal milling. Pulses undergo some basic unit operations during pulse milling such as cleaning and grading, drying, loosening of husk, dehusking, splitting and polishing.

15.2 Methods of Pulse Milling

15.2.1 Wet milling of pulses

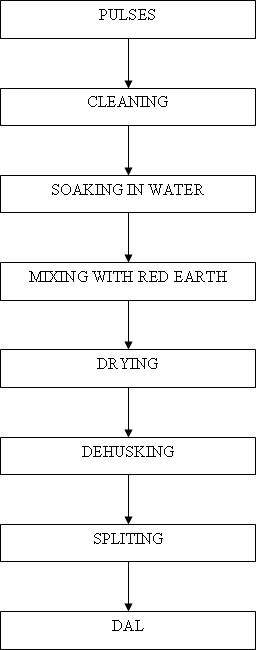

Wet method of pulse processing (Fig. 15.1) involves cleaning to remove dust, dirt, chaff, stone pieces, immature grains and other seeds. The easy to dehusk pulses are then soaked into water for a period of 2 – 8 hrs whereas difficult to dehusk type of pulses (pigeonpea, black gram, green gram) are often treated with red earth. The pulses are subsequently dried and then subjected to dehusking and splitting to obtain Dal.

15.2.2 Dry method of pulse milling

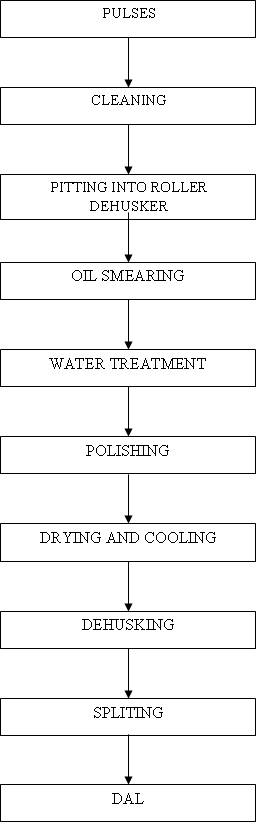

In case of dry method of pulse milling (Fig. 15.2), the pulses after cleaning are fed into roller dehusker where a scratch, dent and crack is formed on the outer seed coat. Pitted pulses are then stored for ˝ day to 3 days after applying oil on the surface. Generally 150 – 250 gm oil per 100 kg pulses is applied. The oil diffuses between husk and cotyledon and thus facilitates loosening of the husk. Water treatment (2.5 – 3.5 kg water/100 kg pulses for overnight period) helps in further loosening of the husk. Then the pulses are subjected to drying and cooling. Now, the dried pulses are dehusked and splited to obtain dal.

Fig. 15.1 Wet milling of pulses

Fig. 15.2 Dry milling of pulses

15.3 Home Scale Milling of Pulses

The home scale method of processing of pulses involves pounding of pulses into mortar and pestle. Home scale method of pulse milling is different for different pulses and varies from region to region. In this method, the husk is loosen either by wet or dry method; treating the pulses with water and/or oil. The pulses are then generally stored overnight and the next day they are sun dried. The removal of husk is then carried out in pestle and mortar or by a hand operated stone mill. The husk then is separated by winnowing.

15.4 Commercial Scale Milling of Pulses

15.4.1 Cleaning and Grading

Pulses received at the mill needs to be cleaned and size graded for yielding good quality dal with higher recovery. Even during dehusking operation, pulses are subjected to sieving to separate out husk, brokens, splits, gota (dehusked pulse) and whole (unhusked) pulses. Usually two, types of cleaners are used: reciprocating air-screen cleaners and reel screen cleaners.

In reciprocating air screen cleaners air is blown through two screens (sieves) which separate out lighter material such as dust, stalk, dried leaves, husk etc. The upper screen has bigger perforations while second screen has smaller perforations. The reel screen cleaners consist of 2-4 cylindrical compartments. The frame of the machine is made of wooden or mild steel sheet. In these compartments different size perforation screens are fitted on a 5-7.5 mm diameter shaft. The machine is fitted at an inclination of 2-3°. The cylindrical screen drum rotates at 5-35 rpm.

15.4.2 Drying of Pulses

Drying of pulses is necessary to ensure safe storage before milling as pulses received at mill have generally higher moisture content. After steeping of pulses for loosening of husk, it is also necessary to dry pulses. During splitting operation too, it is very much essential to dry the pulses to separate cotyledons. Sun drying of pulses is economical option for drying of pulses. The sun drying is done for 1-6 days as per the requirement. The pulses are spread over floor/roof in 5 to 7.5 cm thick layer which are intermittently stirred manually with the help of rakes or turning by foot. At night, the drying pulses are collected in heaps and covered with canvass sheet to preserve the heat. Mechanically heated air dryers, either batch type or continuous flow type are also used by the millers. The temperature of heated air for drying varies from 60° to 120°C.

15.4.3 Loosening of Husk

This is very important step in pulses milling as it decides the total recovery and quality of milled dal. Loosening of husk is accomplished in two different ways: wet method and dry method.

15.4.3.1 Wet Method

Cleaned and graded pulses are soaked in water for 4-12 hours for steeping, mixed with red earth for 12-16 hours and then sun dried to keep the moisture content about 10-12 %. During steeping the husk becomes loose and thus facilitates easy dehusking and splitting. Yield is also increased due to lesser breakage. But cooking time increases when the dal is obtained by this method. Red earth is used as it impart a good yellow colour to the end product and also helps to remove small patches of adhering husk due to its mild abrasive quality.

15.4.3.2 Dry method

In this method, husk is loosened by sequence of operations such as: oil smearing, water application, tempering and sun-drying. Cleaned and graded pulses are passed through roller dehusker in which scratches, cracks and dents are created on hard seed coat of pulses. This is known as ‘pitting’ of pulses. The pitted pulse grains are then passed through the sieve cleaner to separate out the splits, husk and powder and later smeared with oil (100-500 gram per quintal of pulses) either manually or with auger mixer and stored for 1-5 days. During this tempering period oil diffuses in between the husk and cotyledons and weakens the bond and thus facilitates loosening of the adhering husk. At the end of storage period, water is applied to the grains (1-5 kg/q) and stored for further 12-14 h (overnight) and at last sun-dried for 1-3 days before subjecting to milling.

15.4.4 Dehusking

Roller dehuskers coated with carborandum are used to dehusk the pulses. Two types of rollers viz. cylindrical and tapered are available for dehusking. Tapered rollers are placed horizontally and the diameter of roller increase from feeding side to discharge side. The difference in diameter helps to gradually increase the pressure on pulse grains and thus helps in gradual dehusking. The cylindrical rollers are installed at an angle of 10-15° which enables forward movement of pulse grains inside the machine. Annular gap between rollers varies depending upon the type of pulses being dehusked. Inlet and outlet of the roller machine can be adjusted for regulation of grain flow and retention time respectively. Small dal mills use under run disc shellers or burr mills for dehusking operation in place of Roller mills.

Conditioned pulse grains subjected to mild abrasion inside the roller machine, removes 10-25% of husk in one pass. Shelled husk, cotyledon powder, brokens and splits are separated out by Air-screen cleaners after passing the grain lot once or twice through the roller machine. Depending upon adherence of husk to grain, the pulse grains are passed through mill for two to eight times.

For hard-to-dehusk pulses (arhar, moong, urad), the recovery is between 70-75% while for easy-to-dehusk pulses (bengal gram, lentil, kesari and peas), it varies in between 78-85%.

15.4.5 Splitting

Splitting operation involves loosening the bond between the cotyledons and splitting. For cotyledons loosening, water at the rate of 1-5 kg/quintal is applied to dehusked pulse grain (gota) and is stored for 2-12 hours and later sun-dried for 4-8 hours. For splitting, machines like under-run-disc sheller (URD), impact machine (Phatphatia), roller mill, and hitting the gota against the metal sheet at discharge side of bucket elevator are used. In this operation the embryo attached to two cotyledons breaks away, thereby, causing a loss in dal recovery by 1.5 to 2%.

15.4.6 Polishing

In this operation dal is imparted with a glazing appearance to improve its consumer’s acceptance and market value. Depending upon the need, different materials like water, oil, soapstone powder and ‘selkhari’ powder are applied to dal surface. Sometimes removal of sticking powder from dal surface is considered sufficient to improve its surface glaze.

15.4.6.1 Removal of powder/dust

Cylindrical rollers mounted with the rubber mats, leather strips, emery rollers are used for the purpose. The dust particles sticking to dal surface are removed by gentle rubbing action on the roller surface.

15.4.6.2 Water polish

This is used for hard-to-dehusk pulses. In this method 1-1.5 kg of water per quintal of dal is applied while passing it through polisher.

15.4.6.3 Buff polish

In this method 2-2.5 kg of water and 200-250g of oil per quintal of dal is applied while passing it through polisher.

15.4.6.4 Nylon polish

Soapstone powder or ‘selkhari’ powder (1-1.5kg/q) is applied to the surface along with water (1-1.5 kg/q) while passing through the polisher. Screw conveyors battery for repeated rubbings is used. The flights and shafts are covered with nylon rope to impart gentle rubbing.

15.4.6.5 Teliya dal

2.5 to 3.0 kg of castor oil is mixed per quintal of arhar dal to make it look glossy. The storage life of teliya dal is short.