Module 8. Chhana based sweets

Lesson 18

RASOGOLLA- PRODUCT DESCRITION PREPARATION, QUALITY-PACKAGING AND SHELF LIFE

18.1 Introduction

Rasogolla popularly known as king of Bengal sweets. Product was developed by Nobin Chandra Das in 1868. Production is largely confined to cottage and small scale industry. K. C. Das used to be a brand name for rasogolla in past. At present many industries like Bikaner, Haldiram Foods etc., produce the product. Export markets for canned rasogolla are US, some part of Europe, and UAE. Canning helps to expand distribution of rasogolla in domestic and international markets.

18.2 Product Description

Rasogolla resembles ping-pong ball in shape, snow-white in colour and possesses a spongy, slightly chewy body and juicy and smooth texture. Rasogolla balls are stored and served in sugar syrup. The product is flavoured with kewara, pista and rose and sometimes centered with cardamom or pista.

18.3 Rasogolla Preparation

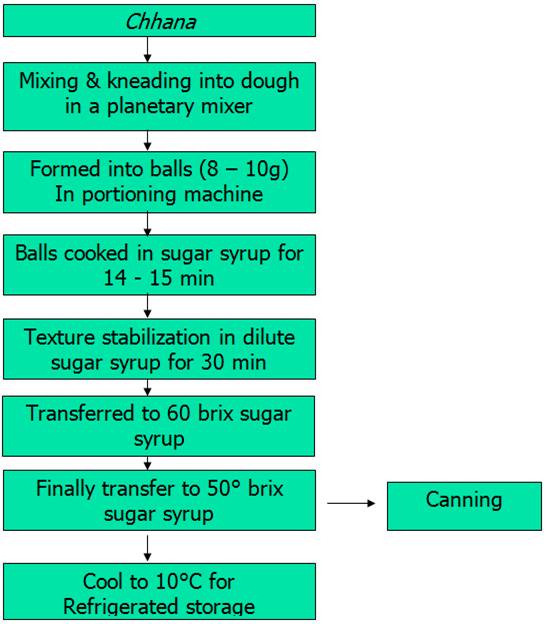

Rasogolla is prepared from soft, fresh cow milk chhana. Kneading of chhana to smooth paste by manually or using planetary mixer is first step in Rasogolla making. The smooth paste is portioned and rolled between palms to form balls of about 15mm diameter each weighing about 8 10g in weight. Each ball should have smooth surface without visible cracks on surface. On an average, one kg chhana yields 90 100 rasogolla balls. These rasogolla balls are cooked in sugar syrup of approximately 50° Brix. Heating is regulated to maintain stability of the balls. Balls are cooked for 14 15 min. During cooking small amount of water is continuously added to maintain syrup concentration. This makes up for the loss of water due to evaporation. About 10% of sugar syrup should be replaced with fresh one each time to cook another batch. After cooking rasogolla balls are transferred to dilute sugar syrup at 60°C for texture and colour improvement. After 30min stabilized balls are transferred to 60° Brix syrup for 1-2 hours, followed by final dipping in 50° brix syrup. Chemical composition of rasogolla is given in Table 18.1

Table 18.1 Chemical composition of rasogolla

|

Sl. No. |

Parameter |

Rasogolla made from cow milk |

Rasogolla made from buffalo milk |

|

1 |

Moisture (%) |

54.0 56.0 |

41.5 42.1 |

|

2 |

Total solids (%) |

44.0 46.0 |

57.9 58.5 |

|

3 |

Protein (%) |

5.0 5.2 |

5.3 5.8 |

|

4 |

Fat (%) |

4.8 5.0 |

7.8 8.0 |

|

5 |

Carbohydrate (%) |

33.6 35.1 |

43.6 44.1 |

|

6 |

Ash (%) |

0.75 |

0.7 |

|

7 |

pH |

6.50 - 6.70 |

6.67 - 6.79 |

(Source: A. Haque et al.,(2003). Pakistan Journal of Nutrition 2 (5): 296-299)

Fig. 18.1 Flow diagram for manufacture of rasogolla

18.3.1 Preparation of cooking medium

Sugar syrup preparation includes dissolution of sugar in water and boiling till it is concentrated to desired brix level. While boiling, scum appearing on top of the surface is scooped off before cooking the rasogolla balls. Pinch of milk can be added during boiling to remove the scum.

Following table listed the BIS standards for rasogolla

Table 18.2 BIS Standards for rasogolla

|

Parameter |

Specifications |

|

Moisture |

45 55% |

|

Milk fat, minimum |

5% |

|

Sucrose, maximum |

45% |

|

Protein, minimum |

5% |

|

Acidity of syrup(ml of N/10 NaOH required to neutralize 100ml of the syrup), maximum |

6 |

|

Concentration of syrup, maximum |

55oBrix |

|

Bacterial count, per gram, maximum |

500 |

|

Coliform count, per gram |

Nil |

18.4 Mechanized Production of Rasogolla

Mechanical disc grinder has been designed for better kneading of chhana. Screw conveyor with kneading section and cutter provided at the exit simultaneously perform the kneading and portioning of chhana into lumps of about 10g each. This lump is allowed to fall on a spinning disc, which has a stationary mounting above it. Rotation of lumps of chhana with stationary mounting forms it into the spherical balls. Recently rotating plate over a conveyor belt is also in use for ball formation. Now these balls can be made to fall directly into sugar syrup for cooking. Alternatively mechanized cooker can also be used for cooking; advantages are uniform weight and shape of rasogolla balls, large production, and uniform quality.

18.5 Yield of Rasogolla

90-100 rasogolla balls of diameter 30mm can be made from one kg of chhana. The yield is 254g (drained weight) of rasogolla per 100g of cow milk chhana and 342g of rasogolla per 100g of buffalo milk chhana.

18.6

Packaging of Rasogolla

Balls are usually packed hot at 90°C in lacquered tin cans of 1kg capacity. [Empty containers are first sterilized in hot air inside closed chamber. Rasogolla balls with hot sugar syrup and permissible preservatives(Sorbic acid and its sodium, potassium and calcium salts calculated as sorbic acid maximum 1000 ppm and Benzoic acid maximum 300ppm) are filled into containers and pass through steam chest]. After seaming, the containers are transferred to chilled water to create partial vacuum by quick condensation of the vapours inside the container.

18.7 Shelf life of Rasogolla

Rasogolla can be store for 2 3days at room temperature without any packaging and added preservatives. Shelf life of rasogolla in tin cans is reported to be 6 months.