Module 3. Transformers

Lesson 10

TRANSFORMER THEORY-I

10.1 Introduction

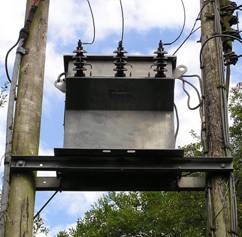

Transformer is used to increase or decrease the voltage. Transformer is an important electrical machine in a power system (Fig. 10.1). A transformer is a device that transfers electrical energy from one circuit to another through inductively coupled conductors—the transformer's coils. A varying current in the first or primary winding creates a varying magnetic flux in the transformer's core and thus a varying magnetic field through the secondary winding. This varying magnetic field induces a varying electromotive force (EMF), or "voltage", in the secondary winding. This effect is called inductive coupling.

Fig. 10.1 A pole mount transformer

Electrical power is generated at power plant (Thermal/Hydel/Nuclear) generally at 11 kV. The voltage is stepped up to 220 kV or 400 kV for transmission to long distances. It is done to reduce loss and increase distribution efficiency. Transformer can be broadly classified as:

10.1.1 Step up transformer

When output voltage is greater than input voltage (V2>V1).

Fig. 10.2 Step up transformer

10.1.2 Step down transformer

When output voltage is less than input voltage (V2<V1).

Fig. 10.3 Step down transformer

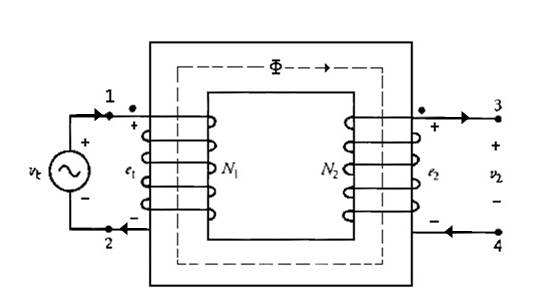

10.2 Principle of Operation

Transformer works on the principle of electromagnetic induction. The basic elements of a transformer are (Fig. 10.3):

1. Steel core: on which primary and secondary winding are done.

2. Primary winding: a.c. supply is connected.

3. Secondary winding: Load is connected.

When primary winding is connected to a.c. voltage V1, an alternating flux is set up in the core. This alternating flux links with the secondary winding through the steel core. An e.m.f. is induced in the secondary winding known as mutually induced e.m.f. According to Lenz’s law the direction of induced e.m.f. V2 is opposite to the applied voltage V1 (Fig.10.4).

Fig. 10.4 Direction of induced emf in secondary coil is opposite to applied voltage

The primary and secondary windings are not connected but due to mutual flux emf is induced in the secondary coils.

10.3 E.m.f. Equation of a Transformer

Consider a transformer having

N1 number of turns in primary side

N2 number of turns in secondary side

The transfer is updated by a.c input of frequency f. Let Φm be the maximum flux in the transfer core.

Φm = Bm × A

Where

Φm = Maximum flux in core , Wb

Bm= Maximum flux density

A = area of core

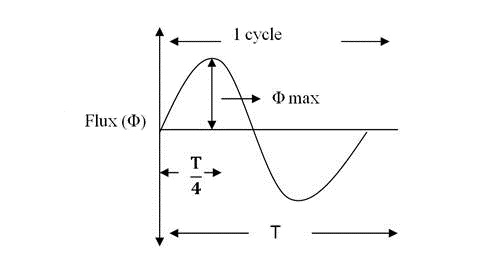

Fig. 10.5 Wave form of alternating flux

From above figure it is evident that flux increase from zero to the maximum value Φm in T/4 seconds.

![]()

![]()

![]() ......... (1)

[Since T = 1/f]

......... (1)

[Since T = 1/f]

We know,

Form factor = r.m.s. value/average value = 1.11

Or, r.m.s value = 1.11 × average value ......... (2)

From eqn (1) & (2)

r.m.s value of e.m.f/ turn = 1.11 × 4 f Φm volts

= 4.44 f Φm volts/turn

r.m.s value of induced emf in primary winding having N1 turns

E1 =4.44 f Φm N1 volts ......... (3)

r.m.s value of induced emf in secondary winding having N2 turns

E2 = 4.44 f Φm N2 volts ......... (4)

Dividing equation (4) & (5)

![]()

Or

![]() .........

(5)

.........

(5)

The ratio of secondary voltage (E2) to primary voltage (E1) is known as transformation ratio (K).

· Step up transformer N2 > N1 or K > 1

· Step down transformer N1 > N2 or K < 1

In case of an ideal transformer

Input power = output power

![]()

or

![]()

![]() .........

(6)

.........

(6)

From (5) & (6)

![]()

10.3.1 Turn ratio

The ratio of secondary to primary turns is called turn ratio,

turn ratio= N2/N1.

If N2>N1 transformer is step-up transformer

If N2<N1 transformer is step-down transformer.

The relationship between transformation ratio and turn ratio is given as:

![]()

10.4 Working

When an alternating voltage V1 is applied

to the primary, an alternating flux ![]() is

set up in the core. The alternating flux links both the windings and induces e.m.f.s E1 and E2 in them according

to Faraday’s laws of electromagnetic induction. The e.m.f.

E1 is termed as primary e.m.f. and e.m.f. E2 is termed as secondary e.m.f.

is

set up in the core. The alternating flux links both the windings and induces e.m.f.s E1 and E2 in them according

to Faraday’s laws of electromagnetic induction. The e.m.f.

E1 is termed as primary e.m.f. and e.m.f. E2 is termed as secondary e.m.f.

![]()

![]()

![]()

Note that

magnitude of E2 and E1 depend upon the number of turns on

the secondary and primary respectively. If N2>N1, then

E2>E1 (or V2>V1) and we get a

step-up transformer. On the other hand, if N2<N1, then

E2<E1 (or V2<V1) and we get a

step-down transformer. If load is connected across the secondary winding, the

secondary e.m.f. E2 will cause a current I2

to flow through the load. Thus, a transformer enables us to transfer a.c. power from one circuit to another with a change in

voltage level. The following points may be noted carefully:

· The transformer action is based

on the laws of electromagnetic induction.

· There is no electrical connection

between the primary and secondary. The a.c. power is

transferred from primary to secondary through magnetic flux.

· The transformer cannot work on d.c. power.

· There

is no change in frequency i.e. output power has the same frequency as the input

power.

·

The losses that occur in a

transformer are:

a)

Core losses-eddy current and hysteresis.

b)

Copper losses-in the resistance of the windings.

In

practice, these losses are very small so that output power is nearly equal to

the input primary power. In other words, a transformer has very high

efficiency.

10.5

Application of Transformer

10.5.1

Power distribution

Big

generating stations are located at hundreds or more km away from the load center (where the power will be actually consumed). Long

transmission lines carry the power to the load centre from the generating

stations. Generator is a rotating machines and the level of voltage at which it

generates power is limited to several kilo volts only a typical value is 11 kV.

To transmit large amount of power (several thousands of mega watts) at this

voltage level means large amount of current has to flow through the

transmission lines. The cross sectional area of the conductor of the lines

accordingly should be large. Hence cost involved in transmitting a given amount

of power raises many folds. Not only has that, the transmission lines had their

own resistances. This huge amount of current will cause tremendous amount of

power loss or I2R loss in the lines. This loss will simply heat the

lines and becomes a wasteful energy. In other words, efficiency of transmission

becomes poor and cost involved is high. The above problems may address if we

could transmit power at a very high voltage say, at 200 kV or 400 kV or even

higher at 800 kV. But as pointed out earlier, a generator is incapable of

generating voltage at these levels due to its own practical limitation. The

solution to this problem is to use an appropriate step-up transformer at the

generating station to bring the transmission voltage level at the desired value

as depicted in figure 10.6 where for simplicity single phase system is shown to

understand the basic idea.

Fig. 10.6 Power transmission system

Obviously

when power reaches the load centre, one has to step down the voltage to

suitable and safe values by using transformers. Thus transformers are an

integral part in any modern power system. Transformers are located in places

called substations. In cities or towns you must have noticed transformers are

installed on poles – these are called pole mounted distribution transformers.

These type of transformers change voltage level typically from 3-phase, 6 kV to

3-phase 440 V line and then to 220 V line.

10.5.2

Domestic use

Small transformers are used in the mobile charger, emergency light etc to bring 220 V domestic supply

to low voltage may be 4.5 V or 6 V.

10.6

Construction of Transformer

1. Steel

core: Silicon steel in the form of thin laminations is used

for the core material. The core is laminated to minimize the eddy current loss.

These laminations are coated with a thin layer of insulating varnish, oxide or

phosphate. The thickness of laminations ranges from 0.35 mm to 0.5 mm. The

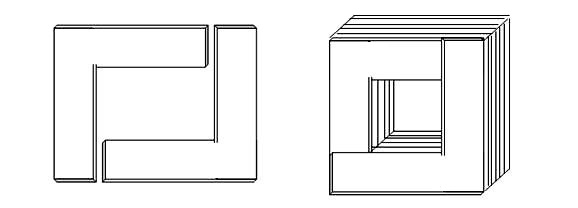

construction can be core type or shell type:

a)

Core type: In a core type construction the winding surrounds the

core. The laminations are cut in L shape and are assembled in form of

rectangular frame (Fig. 10.7). To prevent flux leakage primary and secondary

windings are placed overlapping on the limbs of core.

Fig. 10.7 Core type transformer

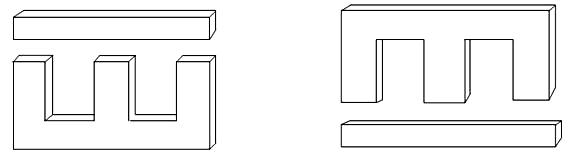

b)

Shell type: In case of shell-type transformer, individual

laminations are cut in the form of long strips of E’s and I’s

as shown in fig 10.8. In order to avoid high reluctance at the joints where the

laminations are butted against each other, the alternate layers are stacked

differently to eliminate continuous joints.

Fig. 10.8 Shell type transformer

In a

shell-type transformer, the core has three limbs, the central limb carries

whole of the flux, where as the side limbs carry half of the flux. Therefore, the width of the central limb as about double to that of

the other limbs. Both of the primary and secondary windings are

placed on the central limb side by side or concentrically. The low voltage

winding is placed nearer the core and the high voltage winding is placed

outside the low voltage winding to reduce the cost of insulation placed between

core and low voltage winding. In this case also the windings are form-wound in

cylindrical shape and the core laminations are inserted later on.

2. Windings:

Windings form another important part of transformers. In

a two winding transformer two windings would be present. The one which is

connected to a voltage source and creates the flux is called primary winding.

The second winding where the voltage is induced by induction is called a

secondary. If the secondary voltage is less than that of the

primary the transformer is called a step down transformer. If the

secondary voltage is more then it is a step up transformer. A step down

transformer can be made a step up transformer by making the low voltage winding

as its primary. Hence it may be more appropriate to designate the windings as

High Voltage (HV) and Low Voltage (LV) windings. The winding with more number

of turns will be a HV winding. The current on the HV side will be lower as V-I

product is a constant and given as the VA rating of the machines. Also the HV

winding needs to be insulated more to withstand the higher voltage across it.

HV also needs more clearance to the core, yoke or the body. These aspects

influence the type of the winding used for the HV or LV windings.

a. Primary winding: a.c. supply is connected.

b. Secondary winding: Load is connected.

3. Container/tank:

It forms the outer covering and body of the

transformer. It is filled with oil in case of oil cooled transformers.

4. Bushings:

Are required for connecting the ends of the winding to

the external circuit. Bushings are made of porcelain and it insulate

the terminals from the transformer body. Two separate bushings are provided for

High Voltage (HV) and Low Voltage (LV) connections (Fig. 10.9).

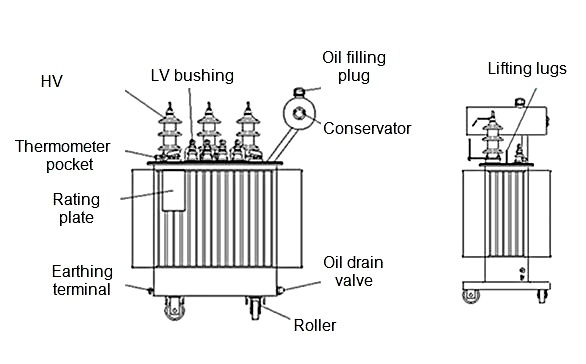

Fig. 10.9 Outer construction of a transformer

5. Cooling

arrangement: Heat is produced in a transformer by the iron losses

in the core and I2R loss in the windings. To prevent undue

temperature rise, this heat is removed by cooling. Type of

cooling methods used are:

·

Dry type transformer: Natural air circulation, air

blast

·

Liquid (oil) immersed: self-cooled, forced air cooled,

forced water cooled, forced oil cooled

a)

In small transformers (below 50 kVA),

natural air cooling is employed i.e. the heat produced is carried away by the

surrounding air.

b)

Medium size power or distribution transformers are

generally cooled by housing them in tanks filled with oil. The oil serves a

double purpose, carrying the heat from the windings to the surface of the tank

and insulating the primary from the secondary. Self oil cooled transformer have

cooling tubes on the outer body. Due to heat dissipation from the winding

convective circulation of oil occurs in the cooling tubes.

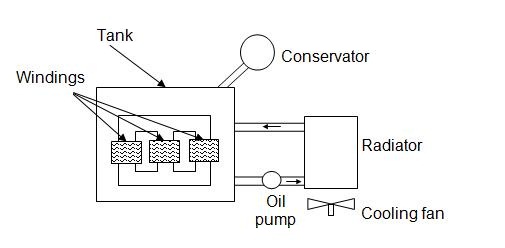

c)

For large transformers, external radiators are added

to increase the cooling surface of the oil filled tank. The oil circulates

around the transformer and moves through the radiators where the heat is

released to surrounding air. Sometimes cooling fans blow air over the radiators

to accelerate the cooling process (Fig. 10.10).

Fig. 10.10 Oil cooled

transformer

Numericals

1. Calculate

transformation ratio if the voltage in the primary and secondary coil are 11000

and 440 volts respectively.

transformation ratio ![]()

= ![]()

2.

Calculate the number of turns in the secondary coils of a transformer if

transformation ratio is 10 and number of turns in primary side is 2500.

Given

K = 10

N1

= 2500

K = N1

/ N2

N2

= 10 × 2500

= 25000 turns.

3.

If the number of turns in the primary and secondary windings of the transformer

is 500 and 1000 respectively. Find the voltage in the secondary side of

transformer. The primary side voltage is 220 V.

transformation

ratio K = N1 / N2 = 500/1000 =0.5

![]()

![]()

E2 = 110 V