Module 6. D.C. machines

Lesson 22

CONSTRUCTION AND PRINCIPLE OF D.C. GENERATOR

22.1 DC Generator

A D.C. Generator converts mechanical energy into electrical energy (d.c. current). A d.c. generator provides direct current. Difference between a.c. and d.c. is as follows:

A.C. = alternating current

D.C. = direct current

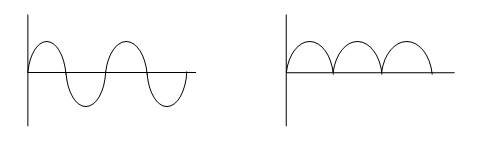

Fig. 22.1 A.C. wave Fig.22.2 D.C. wave form

To understand the working of a d.c. generator, first we need to know the mechanism of current in a coil rotated in a magnetic field. From faraday laws of electromagnetic induction we know emf induced in the coil is directly proportional to the rate of change of flux linkage, i.e.

![]()

Where

N = number of turns in the coil

![]() =

rate of change of flux linkage.

=

rate of change of flux linkage.

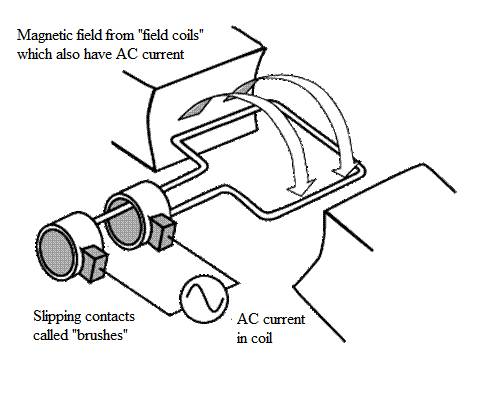

We can see from

fig. 22.3 that for 180° rotation of the coil generates +ve emf and for another

180° rotation it is –ve. Such type of current having +ve and –ve loop is known

as alternating current. Please note that the current is drawn from the coil

using slip ring.

Fig. 22.3 A.C.

generator

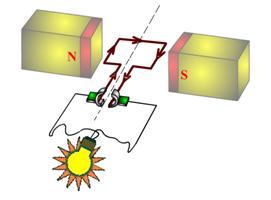

Fig. 22.4 D.C. generator

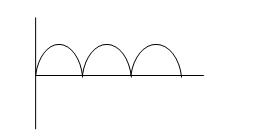

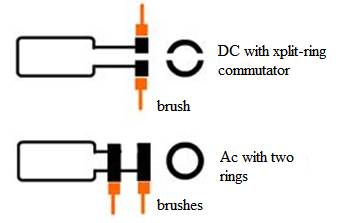

Consider the same setup of magnetic field and coils fitted with split rings. The function of the split ring is to make the current unidirectional. The split ring is cylindrical having two segments separated by an insulator. The carbon brushes touch the segments as shown in figure 22.4. When the coil will rotate in the magnetic field it will produce unidirectional current (Fig 22.5). Difference between A.C. and D.C. generator is the contact type by which current is drawn (Fig. 22.6)

Fig. 22.5 D.C. wave form

Fig. 22.6 Difference between D.C. and A.C. generator

22.2 Construction of D.C. Generator

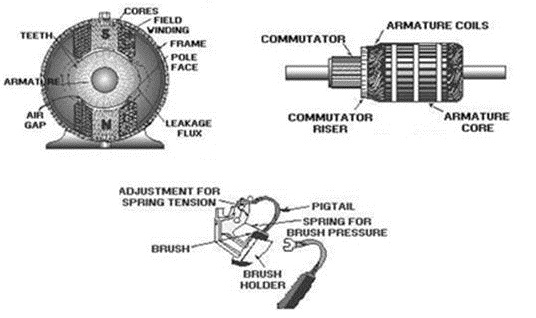

Parts of the D.C. generator are as follows (Fig. 22.7):

1. Frame

2. Field poles

3. Field coils

4. Armature (core + winding)

5. Commutator

6. Brush assembly

Fig. 22.7 Parts of the D.C. generator

22.2.1 Frame

The frame is also known as yoke and acts as housing for poles, armature etc. It gives mechanical support and covers the parts of the machine. The yoke also transmit the magnetic flux provided by the poles. Therefore it is made of steel having higher capacity to carry magnetic flux 1.6 Wb/m2.

22.2.2 Field poles

a. Main poles. It consists of a pole and pole shoes. It is made of laminated sheets to reduce the effect of eddy current in the poles.

b. Inter poles. Also known as a commutation poles and is situated between two main poles.

Fig. 22.8 Main pole and interpole

1. Main pole with exciter winding

2. Compensation winding

3. Rotor with rotor winding

4. Interpole with interpole winding

5. Rotational direction during generator operation

22.2.3 Field coils

Field coils are pre wound to give proper shape and are placed around the main poles. As the current passes through the field coils it magnetizes the main pole.

22.2.4 Armature

a. Armature core: Slots are cut in the thin laminated steel disc. A number of disc are arranged in a shape of cylinder to from the armature core.

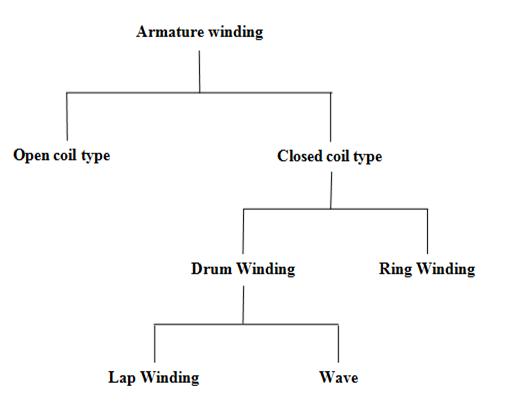

b. Armature winding: The winding of the armature are first wound in form of loop. These windings are of insulated wires. The winding loops are then placed into the slots of armature core. The windings are also called conductors as they carry electric current. Armature winding are of the following types.

Fig 22.9 Classification of armature winding

22.2.5 Commutator

Commutator is mounted next to armature core and winding on the shaft. It is a cylindrical structure and is made up of segments separated from each other by thin strip of mica. The segments of the commutator are connected to the armature winding. The current is then drawn from the Commutator.

22.2.6 Brush assembly

The brush assembly consists of brush, brush holder, studs rocker and bushes. The brushes are made of carbon graphit or graphite. The function of the brush is to collect current from the commutator.