Module 7. Electrical measuring instrument

Lesson 29

PRINCIPLES OF ELECTRICAL MEASUREMENT SYSTEM

29.1 Element of a Generalized Measurement System

There are three elements of any electrical measurement system.

1. Deflecting element

2. Controlling element

3. Damping element

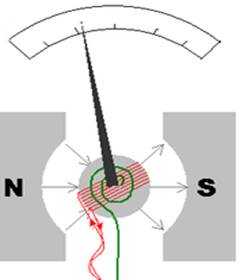

29.2 Deflecting Element

The electrical quantity like current, voltage or power produces the deflecting torque. The deflecting torque carries the pointer to move. There are different mechanisms for deflection like:

a. Coil and soft iron core arrangement.

b. Moving coil and fixed coil system.

c. Moving iron and coil system.

d. Others.

Fig. 29.1 Deflecting element

29.3 Controlling Element

It controls the deflection of the pointer according to the magnitude of the electrical quantities (e.g. current, voltage etc). If controlling device is not provided the pointer will immediately move to maximum position as soon as the instrument starts measuring any electrical quantity. The function of the controlling device is also to bring back pointer to zero position, if the magnitude of measured quantity becomes zero. Controlling devices are of two types:

1. Spring Control

2. Gravity Control

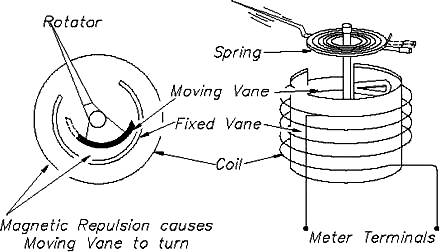

29.3.1 Spring control

Two spiral spring made of non magnetic material wound in opposite ends is used for controlling deflection. As the pointer moves one spring gets winded and other is unwound, thus two springs provides controlling torque. The torsion torque of a spiral spring is proportional to the angle of twist, therefore the controlling torque is directly proportional to the deflection of the pointer.

TC ∝ θ

Where

TC = Controlling Torque

θ = Deflection of pointer

Fig. 29.2 Control element (spring)

29.3.2 Gravity control

To provide controlling torque two weights are attached:

a. Balance Weight – It balance the weight of the pointer.

b. Control Weight – It provides the controlling torque.

Here the controlling torque is directly proportional to the sin of the angular deflection i.e.

TC ∝ sin θ

The control weight is attached to the pointer spindle in a way that its position can be altered. The controlling torque can be varied by changing the distance of the control weight from the pointer axle.

Fig. 29.3 Gravity control by balance weight

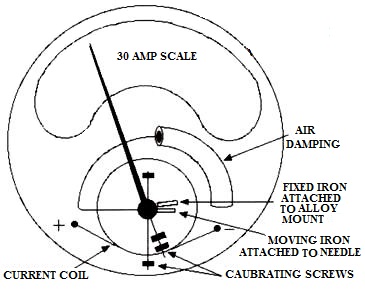

29.4 Damping Element

The pointer of the measuring instrument will move by the deflection and controlling mechanism. The pointer will keep moving to and fro (oscillates) and will come to rest after a long period. Thus it has to wait for long to take the reading from the measuring instrument and it will also result inaccurate result.

To overcome this problem a damping element is provided in the instrument. A damping torque is applied to the pointer by this damping device which brings the pointer to rest. Oscillation / vibration of the pointer is eliminated and reading from the instrument can be taken immediately.

Different methods of damping are as follows:

1. Air friction damping

2. Fluid friction damping

3. Eddy current damping

Fig. 29.4 Damping element (Air damping)