Module 9. Steam and its properties

Lesson 23

USE OF STEAM TABLES & MOLLIER CHART, NUMERICAL PROBLEMS

23.1 Steam Table

All the previously mentioned properties of steam i.e. specific enthalpy, specific volume and specific entropy each of saturated water and steam (wet, dry & superheated) vary with the change in saturation pressure. And for a particular saturation pressure there is a fix value of saturation temperature. These properties are required in thermo dynamic calculations where steam is used as working medium. It is quite cumbersome to calculate each time, the value and relation between various properties. So, these are experimentally determined and presented in the form of tables showing value of each property w.r.t either saturation temperature or saturation pressure. These tables are called steam tables. The value of properties of saturated steam and superheated steam are given separately. If any given pressure falls in between two values given in table then value of concerned property on this pressure may be calculated by interpolation. The column in the steam table showing properties of saturated stream are as given below:

Table 23.1 Stem table format

|

Absolute Pressure in bar (P) |

Saturation Temperature in 0C (t) |

Specific Volume in m3/kg |

Specific Enthalpy in kJ/kg |

Specific Entropy in kJ/kg.k |

|||||

|

Water (vf) |

Steam (vg) |

Water (hf) |

Evaporation (hfg) |

Steam (hg) |

Water (sf) |

Evaporation (sfg) |

Steam (sg) |

||

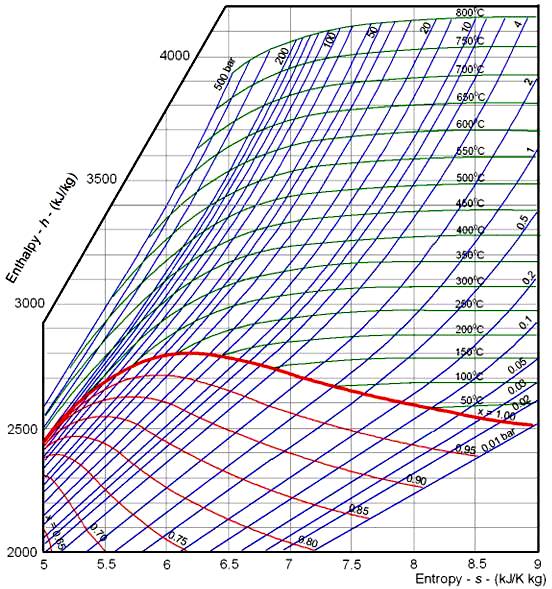

23.2 Enthalpy-Entropy Diagram or Mollier Diagram (H-∅)

It is a plot of enthalpy on ordinate and entropy on abscissa scale. Constant pressure, constant volume and constant temperature lines are also drawn on it.

Fig. 23.1 Mollier chart

Saturation Line or saturation vapour line is also clearly shown as dark red line. This chart is frequently used to show the expansion or compression and heating or cooling of steam, when it is used as a working media in steam engines/turbines. But as far as a dairy or food processing industry is concerned, steam is used only for the purpose of heating and not as a working media. Thus expansion or compression processes of steam are not required, so use of Mollier chart is limited here. In the heating applications, we are mainly concerned with calculating the enthalpy of steam or heat required to prepare steam of required quality. This purpose is solved with the help of steam tables only. So, in the numerical problems mentioned in this lesson, we will be using steam tables only.

23.3 Numerical Problems

23.3.1 Calculate the total heat of 5 kg of steam at an absolute pressure of 8 bar having dryness fraction of 0.8. Also calculate heat in kJ required to convert the steam into dry and saturated steam.

Solution

From steam tables

At pressure 8 bar, hf = 720.9 kJ/kg

hfg = 2046.5 kJ/kg

hg = 2767.4 kJ/Kg

Sp. enthalpy of wet steam

hw = hf + x.hfg

= 720.9 + 0.8 x 2046.5

= 2358.1 kJ/kg

Total heat of 5 kg steam = weight of steam x Sp. Enthalpy = 5x2358.1 = 11790.5 kJ (Ans)

Now total heat of 5kg dry saturated steam = 5x hg = 5x 2767.4 = 13830 kJ

Net heat

required to be supplied for conversion of wet steam into dry saturated

steam = 13830 – 11790.5 = 2039.5 kJ (Ans)

23.3.2 4 Kg of 0.5 dry steam at 6.0 bar pressure is heated, so that it becomes

(a) 0.95 dry at 6.0 bar pressure or

(b) Dry & saturated at 6.0 bar or

(c) Superheated to 300oC at 6.0 bar or

(d) Superheated to 250oC at 8.0 bar

Using steam tables determine in each case the quantity of heat required to be supplied. Take Csup for superheated steam as 2.3 kJ/ kg K.

Solution: Initial Condition of steam are mass, m = 4 kg; x1= 0.5 and P = 6.0 bar

So initial enthalpy (total heat content) of 4kg steam is

H1 = 4[hf +0.5hfg] [Sub Eq. (i)]

From steam table, at 6.0 bar pressure value of specific enthalpy of saturated water, hf and latent heat of steam, hfg are given as

hf = 670.4 kJ/kg

hfg = 2085.1 kJ/kg

Putting these values in equation (i)

H1 = 4[670.4+0.5×2085.1] = 6851.8 kJ ≈ 6852 kJ

Heat Supplied

Case I Final Conditions of Steam are x2=0.95 and pressure, p=6.0 bar. So final enthalpy of steam is

H2 = 4[hf + x.hfg] = 4[670.4 + 0.95 × 2085.1] = 10605 kJ

Net heat supplied = Final Enthalpy – Initial Enthalpy

= H2 – H1 = 10605 – 6852 = 3753 kJ (Ans)

Case II Final Conditions of Steam are pressure, p=6.0 bar. Condition is dry saturated i.e.,

x2 = 1. So final enthalpy of steam is

H2 = m.hg = 4×2755.5 kJ/kg [From Steam Table]

=11022 kJ

Net heat supplied = Final Enthalpy – Initial Enthalpy

= H2 – H1 = 11022 – 6852 = 4170 kJ (Ans)

Case III Final Conditions of Steam are pressure, p=6.0 bar, Superheated to 3000C. Form steam tables, saturation temperature, tS at given pressure 6.0bar is ts = 158.80C. So final enthalpy of superheated steam is H2 = m [hg + CPs (tsup –ts)] = 4[2755.5 + 2.3(300-158.8)] = 12321 kJ

So Net heat supplied = Final Enthalpy – Initial Enthalpy

= H2 – H1 = 12321 – 6852 = 5469 kJ (Ans)

Case IV Final Conditions of Steam are pressure, p=8.0 bar, Superheated to temperature, tsup = 2500C.

From steam tables

At 8.0 bar pressure ts = 170.40C, hg = 2767.4 kJ/kg

So H2 = m [hg + CPs (tsup –ts)] = 4[2767.4 + 2.3(250-170.4)] = 11801.92 ≈ 11802 kJ

Heat

Supplied = H2 – H1 = 11802 – 6852 = 4950 kJ [Ans]

23.3.3 Calculate the entropy and volume of 4.73 kg of superheated steam at pressure 7.8 bar and temperature 240oC. Take Cp for superheated steam = 2.32 kJ/kg. K

Solution

At 7.8 bar Saturation temperature ts = 169.4oC

or Ts = 169.4+273 = 442.4 K

vg = 0.2461 m3/ kg

sg = 6.668 kJ/kg K

tsup = 240oC

so, Tsup = 240 + 273 = 513 K

![]() Sp.vol. of

superheated Steam

Sp.vol. of

superheated Steam

![]()

= 0.2854 m3/kg

Total volume of 4.73 kg of steam = 4.73×0.2854 = 1.3498 m3

Sp. entropy of superheated steam = sg +

![]()

![]()

= 7.0115 kJ/ kg K

Total entropy of

steam = 4.73x 7.0115 = 33.16 kJ/ K (Ans)

23.3.4 A boiler is producing steam at a pressure of 15 bars and quality as 0.98 dry. It was observed that while flowing from boiler to the place of heating through pipes, steam looses 20 kJ of heat per kg. Assuming the constant pressure, while flowing through pipe line, calculate the quality of steam at the place of heating.

Solution

Given conditions of steam in boiler are

Pressure P=15 bar; x= 0.98; Heat loss= 21 kJ/ kg

From steam tables, we find that

At pressure, P=15 bar,

hf = 844.6 kJ/kg

and hfg = 1945.3 kJ/kg

So specific enthalpy of steam in boiler, h1 = hf + x.hfg

= 844.6

+ 0.98 ![]() 1945.3

1945.3

= 2751 kJ/kg

Heat loss = 21 kJ/kg

So net enthalpy of steam at the other end of pipe line or at the place of heating

= 2751−21 = 2730 kJ/kg

To find dryness fraction of this steam x2 we know that enthalpy is

h2 = hf + x2.hfg

or 2730 = 844.60 + x2 ×

1945.3

![]()

23.3.5 In a conical process vat a batch of 50 kg of milk initially at a temperature of 250 C is to be boiled at atmospheric pressure until concentrated to a final mass of 40 kg. Calculate the mass of steam consumed to carry out the process if steam is supplied in dry saturated condition at a gauge pressure of 1 bar and condensate outlet is at 1000 C. Assume 20% of useful heat loss in the vat.

Solution

Sensible heat absorbed by milk

![]()

![]()

= 15900 kJ

Mass of water evaporated from milk = 50-40 = 10 kg

Latent heat of evaporation of water at atmospheric pressure = 2257 kJ (from steam table)

Latent heat of evaporation of 10 kg water = 10 × 2257 = 22570 kJ

Total heat consumed in the process = 15900 + 22570 = 38470 kJ [Sub Eq. (1)]

Now, Absolute pressure of steam supplied = 1.013 + 1 = 2.013 bar

Enthalpy of dry saturated steam at 2.013 bar pressure = hg = 2707 kJ/kg (from steam table)

Enthalpy of condensate at 1000 C = hf = 419.1 kJ/kg (from steam table)

Net heat supplied by one kg steam = 2707 - 419.1 = 2287.9 kJ

Taking 20 % loss in the process

Net heat given by steam to milk = 2287.9 × 0.8 = 1830.32 kJ/kg [Sub Eq. (2)]

Steam consumed to supply total heat

required in the process as given in equation (1).

![]()

= 21 kg (Ans)