Module 10. System of milk procurement and processing, pricing and marketing of milk and milk products

Lesson 23

SYSTEM OF MILK PROCESSING AND PRODUCT MANUFACTURING: AN ECONOMIC VIEW

23.1 Introduction

Though India is a highest producer of milk in the world, only 15 to 20 per cent of the milk is marketed through organized sector comprised of cooperative societies, public and private processing plants. Bulk marketing is limited to processing plants and cooperative societies. In contrast to Indian situation, most of the milk in developed world is consumed in different processed forms. It is something very general to India where overall food markets for processed foods are generally low and same is the case with milk. By all estimates about 75 per cent of the milk purchased by the consumer as liquid milk whether raw or processed. The share of pasteurized milk is only 10 per cent but the demand is increasing at the rate of 15 percent per annum. One fourth of the milk production is processed in the unorganized sector transforming into products like, sweets. Khoa, paneer, curd, lassi, etc. There are small scale milk product manufacturing units which fall in the category of semi-organized sector comprised of creameries, ice-cream units which are manufacturing the similar products as produced by the composite milk plants in the organized sector. They generally serve the local markets but have the important share in processing of milk as well as meeting the consumer’s specific demands. The organized sector comprised of mainly dairy plants, procures surplus milk through Milk Producer’s Cooperative Societies and generally follows the HACCP standards leading to quality of the products, whereas unorganized sector is composed of milk vendors, contractors, halwaies and creameries , collect milk from producers and sell either as raw milk or manufactured milk products or both.

23.2 Milk Processing and Product Manufacturing

Milk being a perishable product requires immediately processing. The main difference between processing and manufacturing is that when a milk product undergoes a physical change, like milk to curd, milk to ghee, it is manufacturing of product and if raw milk to pasteurized milk like double toned milk this is the case of milk processing. The choice depends on available equipment, product demand and on the quantities of milk available for processing.

23.2.1 Processing of milk

· Once the milk has been inspected, it is moved from the tanker and mixed with the rest of the milk supply in a clarifier. Since the milk comes from many different dairy farms, it has different amounts of cream. Therefore, the milk must be blended during a process called standardization until it all contains the same amount of butterfat.

· Now, processing can begin. In the first step, milk is pasteurized which means that it is heated by a series of plates then cooled quickly back down to its normal storing temperature. Pasteurization kills any disease-causing bacteria that may be present in the supply and helps to make the milk stay fresher for a longer time period.

· The milk then travels to a separator that separates the butter fat out of the milk and then give the milk the proper amount of fat content. During the next step, milk undergoes a homogenization process in which the milk is forced through tiny openings under high pressure. This breaks down the fatty globules of cream so that the cream will not float on top of the milk, and every drop of milk will contain equal amounts of cream.

· During processing, vitamins A and D can also be added to the milk in a step called fortification. Furthermore, tests are run regularly on milk samples in the dairy plant labs that check for its water content, fat percentage, and for the presence of bacteria. The water that is in milk is not added on purpose, but it is water from the machinery that is accidentally mixed into the milk supply. The maximum water content in milk that government allows is 1.8%. This whole procedure from the standardization of milk to its pasteurization is called processing.

23.2.2 System of milk processing and product manufacturing

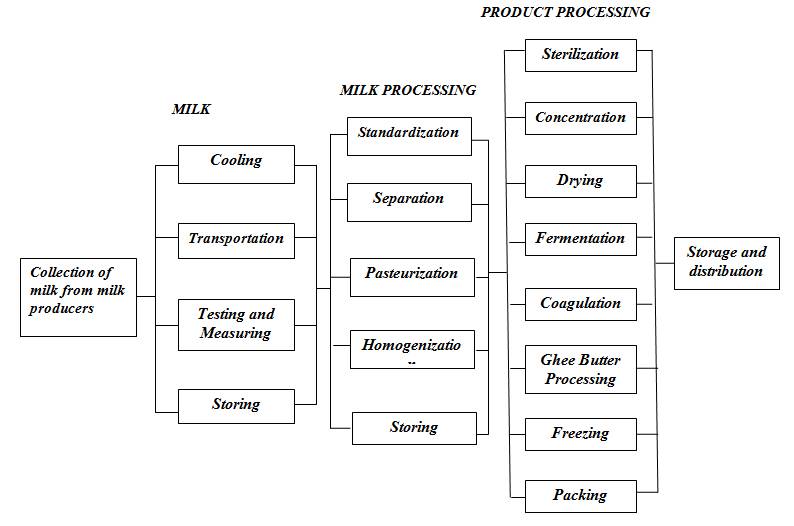

Fig. 23.1 Milk processing and product manufacturing system

23.3 Economic aspect of Milk Processing and Product Manufacturing

Process-wise costs for processing of milk and products manufacturing were worked out in a study conducted by the author in a dairy plant. This case study will be useful for understanding the cost of different processes in manufacturing of products. The process wise costs presented here refer to the year 2000-01. Though the data for cost point of view is old but for understanding the process and system of production or steps in production with reference to percentage wise cost are of great importance.

23.3.1 Full cream milk

The total cost of full cream milk manufacturing was worked out to be Rs. 14.69 /litre (Table 23.1). Raw material share was observed as 91.98% in the total cost. Out of the different processes of manufacturing, the highest cost was recorded for ‘Packaging process’ i.e., 3.33 % followed by the process of ‘pasteurization / Standardization’ (1.53 %); ‘Separation’ (1.31 %); ‘Storage’ (1.16 %) and ‘Reception of milk’ (0.69 %).

Table 23.1 Process-wise cost of full cream milk

|

Items of Expenditure |

Total Annual Expenditure (Rs.) |

Unit Cost Rs./Lit. |

Percentage |

|

Raw Material |

135813207.49 |

13.51 |

91.98 |

|

Reception of Milk |

1005427.45 |

0.10 |

0.69 |

|

Separation |

1942519.74 |

0.19 |

1.31 |

|

Pasteurization/Standardization |

2265138.42 |

0.23 |

1.53 |

|

Packaging |

4919947.93 |

0.49 |

3.33 |

|

Storage |

1711190.99 |

0.17 |

1.16 |

|

Overall |

147657432.02 |

14.69 |

100 |

|

Total quantity produced 10054279.50 litre per annum |

|||

23.3.2 Toned milk

The information in Table 23.2 revealed that the total cost of manufacturing the toned milk was worked out as Rs. 10.85, of which the share of raw material cost was the highest (91.62 %). Amongst the different processes of manufacturing the highest cost was observed in the process of ‘Separation’ (1.38 %); followed by ‘Pasteurization / Standardization’ (1.29 %); ‘Storage’ (1.29 %); and minimum in Reception of milk’ (0.64 %).

Table 23.2 Process-wise cost of toned milk

|

Items of Expenditure |

Total Annual Expenditure (Rs.) |

Unit Cost Rs./Lit. |

Percentage |

|

Raw Material |

31293972.78 |

9.94 |

91.62 |

|

Reception of Milk |

220380.09 |

0.07 |

0.64 |

|

Separation |

472243.05 |

0.15 |

1.38 |

|

Pasteurization/Standardization |

440760.18 |

0.14 |

1.29 |

|

Packaging |

1290797.67 |

0.41 |

3.78 |

|

Storage |

440760.18 |

0.14 |

1.29 |

|

Overall |

34158913.95 |

10.85 |

100.00 |

|

Total quantity produced 3148287 litre per annum |

|||

23.3.3 Ghee

Ghee was manufactured direct from boiling of cream and after the process of clarifying and setting, the ghee was packed in polythene by pre-pac machine and then, it was further packed manually in the cartoons. The component-wise cost of ghee manufacturing was worked out for Ghee is depicted in Table 23.3. As evident from the table that the total cost of ghee manufacturing was worked out as Rs. 120.97 per kg. of which the maximum cost was shared by Raw material, i.e., 94.01 per cent. Out of the five processes in ghee manufacturing, the highest cost was observed in ‘Packaging Process’ (3.60 %) followed by ‘Boiling of Cream’ (0.89 %), ‘Settling and Clarification’ (0.74 %),’Storage’ (0.63 %) and ‘Reception of Milk’ (0.13 %).

Table 23.3 Process-wise cost of Ghee

|

Items of Expenditure (Rs.) |

Total Annual Rs/Lit. |

Unit Cost |

Percentage |

|

Raw Material |

9607747.92 |

113.72 |

94.01 |

|

Reception of Milk |

13704.52 |

0.16 |

0.13 |

|

Boiling of Cream |

91385.57 |

1.08 |

0.89 |

|

Settling & Clarification |

75414.54 |

0.89 |

0.74 |

|

Packaging |

367622.26 |

4.36 |

3.60 |

|

Storage |

63950.30 |

0.76 |

0.63 |

|

Overall |

10219825.11 |

120.97 |

100.00 |

|

Total quantity produced 84486 kg. per annum |

|||

23.3.4 Ice cream

The plant under study was receiving the raw material for manufacturing ice cream from the Mother Dairy. The Plant was providing the services for manufacturing the ice – cream and in exchange getting the processing charges from the Mother Dairy. The processing cost worked out for ice- cream is exhibited in Table 23.4.

Table 23.4 Process-wise cost of Ice cream (2000-2001)

|

Items of Expenditure (Rs.) |

Total Annual Rs./Lit. |

Unit Cost |

Percentage |

|

Raw Material* |

- |

- |

- |

|

Mixing & Heating |

309396.25 |

0.98 |

11.75 |

|

Homogenization/ Pasteurization |

278855.39 |

1.88 |

10.59 |

|

Freezing & Filling |

644416.43 |

2.04 |

24.48 |

|

Storage & Hardening |

1399986.35 |

4.45 |

53.18 |

|

Overall |

2631654.42 |

8.35 |

100.00 |

|

Total quantity produced 314828.70 litre per annum |

|||

*Mother Dairy Plant supplied raw material, the plant was only receiving the processing charges for job work from Mother Dairy.

The total processing cost of ice cream manufacturing was worked out to be Rs. 8.35 per litre. The cost of raw material was not included in the Ice cream as the raw material for the Ice cream was supplied by Mother Dairy. Out of the total four processes of ice-cream manufacturing, the cost worked out for the process of ‘Storage and Hardening’ was found to be the highest (53.18 %) followed by ‘Freezing & Filling’ (24.48 %), ‘Mixing and Heating’ (11.75 %) and ‘Homogenization/Pasteurization’ (10.59 %).

Selected references

Chauhan, A.K , Kalra, K.K., Singh Raj Vir, and Raina B.B. 2005. Economic analysis of manufacturing milk products in a dairy plant, NDRI Publication, Research Bulletin No. 21/2005:1-48.