Appendix A. System analysis for milk procurement and billing system

CASE STUDY - I

SYSTEM ANALYSIS FOR MILK PROCUREMENT AND BILLING SYSTEM

A.1 Introduction

The case study for preparing system analysis report for milk procurement and billing system of a dairy plant is discussed in this section. This sample report may be used for preparing reports for other case studies like Milk marketing system, Milk product manufacturing system. These topics will be useful to understand the minor issues involved in preparing report on system analysis.

A report prepared by system analyst on the system study and analysis should have following contents:

Contents

1. Problem Definition and Introduction.

2. Introductory Investigation.

3. System Analysis.

3.1 Detailed Investigation

3.11 Organizational Chart.

3.12 Review the present system.

3.13 Analyze Inputs.

3.14 Review methods, procedures and data communication.

3.15 Analyze Outputs.

††††††††††††††††††††††††††††††††† 3.16 Model the existing logical system.

3.17 Other analysis and considerations.

3.2 Concluding Investigation

3.21 Context diagram of MPBS.

3.22 Expected volume of data.

3.23 Feasibility study.

3.231 New MIS alternatives.

3.232 Advantages, disadvantages and cost comparison.

3.233 Comparative statement.

3.3 Final Survey Report for top management

3.31 MPBS in brief.

3.32 Major Problems of MPBS.

3.33 Redefined Objectives.

3.34 Main Benefits expected - qualified and quantitative.

3.35 Recommendation.

A.2 Problem Definition

A dairy plant is procuring milk from the nearby villages through a well established network of societies/ collection centers in the radius of 120-200km. Milk producers are paid for the milk based on the prices decided by the management. The management of dairy plant is interested in developing general purpose computerized milk procurement and billing system considering all the procedures of milk procurement and billing.

A.2.1 Problem introduction

A large number of dairy plants are operating in the business of milk procurement and manufacturing milk products. Some of these are owned by the federations/societies registered at state/district level and some are managed by private personnel.

Success of a dairy plant primarily depends on a well panned and organized system of milk procurement. In cases where procurement system is not well established, dairy plants remain underutilized.

The dairy plant gets more than sufficient milk during the flush season (October to March) and it generally fails to meet the demand of the consumers during the lean season (April to September). Hence the management of the dairy has to take up measures to procure sufficient quantity of milk through-out the year. A well planned milk procurement system has the following advantages:

I. An assured market to the milk producersí through-out the year at reasonable price.

II. Full capacity utilization of the dairy plant.

III. Increase in the milk production and collection.

The cost of procurement of milk is sometimes as high as 10 to 15% of the cost of its production. For an efficient determination of this component of cost, the use of computer has been found imperative. Further a quick billing system for the procurement of milk from different agencies has been possible with the employment of computer for maintenance of various accounting systems.

A.2.2 Organizing an MIS project

The task was given to MIS section of the dairy plant and asked to prepare a report for improving the efficiency in present manual method of milk procurement & billing system.

The management of dairy plant established an MIS executive steering committee, consisting of heads of Procurement section, Account & bill section and General Manager (operations). The committee will be responsible for computerizing the activity on behalf of management. The committee will review priorities, objective of the milk procurement and billing systems and will be giving directions to the concerned users of such a system. The committee will also coordinate with the MIS task force, consisting of In-charge of MIS section and two system analysts. The MIS task force is to study the feasibility of upgrading and computerizing the current milk procurement and billing system.

A.3 Introductory Investigation

A.3.1 Defining the scope of MIS project

The MIS task force interviewed various officials like MD of plant, chief milk procurement officer, and field staff of procurement section, supervisor of chilling centre, chairman and employees of collection centre/society. MIS task force also visited some of the societies/collection centers and discussed the possible improvement in the system. In particular the task force was especially interested in identifying the effective and ineffective aspects of the existing system. The main questions asked are as under:

i).

Why

a computer based system being is considered?

ii).

What

are the basic objectives of the proposed system?

iii).

What

is the volume of data to be processed?

iv).

What

is the frequency of processing?

The task force also discussed with the members of the society/collection centers about the kind of services they expected. All the members were satisfied with the concept and kind of activities performed by societies/centers. But they were unhappy over the unusual delay in payments and in providing technical input services. Moreover sometimes mistakes/errors occur in payments and measurement of quantity and quality of milk. Presently the payment is made to members thrice in a month i.e. upto 10th, 20th and 30th day of the month. Further the plant takes at least one week to process the data manually and the payment is done about 8 or 9 days after the due date and sometimes even later than that one more complaint made by the members, supervisors of societies/collection centers and chilling centers was that the management takes a lot of time in solving the disputes over incorrect payments and other irregularities. The same is time with the providing of technical input aids/services. These problems are causing dissatisfaction among the members and discouraging the milk procurement activities.

MIS task force held several rounds of meetings with MIS executive committee and users to present the facts they had gathered. At this time it is difficult to work out the monetary benefit but definitely the computerization of milk procurement and billing system will increase the membership of societies/collection centers which in turn will increase the revenue of the plant. The most important factor is the improvement in the quality of services given to the members. Together, they developed a set of objectives for computerization of existing system as described below. These objectives are thought to be very challenging, but of course attainable.

∑

Providing

better services to the members of society/collection

centers.

∑

Improving

the payment system.

∑

Monitoring

the performance of milk procurement.

∑

Monitoring

technical input services programme.

∑

Providing

timely information to the management.

∑

Enhancing

the milk procurement.

A.3.2 Schedule of MIS

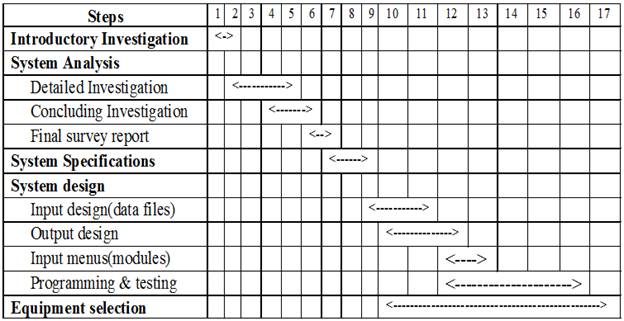

The MIS executive steering committee strongly emphasized the importance of this project in improving the efficiency of the system and urged the MIS task force to set a completion date as early as possible. The MIS task force in turn prepared a list of the major activities to be performed during the system analysis and system design phases and estimated the weeks required to complete each task as shown in fig. A.1 using Gantt chart. MIS task force concluded that the system analysis study could be completed by two system analysts in about seven weeks.

Fig. A.1 Activities involved in analyzing and developing MPBS

A.3.3 Presentation of result of introductory investigation

After reviewing the system with user group, the MIS task force and the MIS executive steering committee met the managing director of plant to present the result of the introductory investigation. The main focus of the presentation was that poor services to the members of societies/collection centre led to the decrease in the strength of membership which is causing direct financial losses to the plant. The MIS task force then explained the concept of integrated milk procurement from society/collection centers, transportation to main dairy dock yard, processing of bills, monitoring of technical input services. They also told that with reduction of time gap to 1/2 days or few hours for payment will satisfy the members and will be effective in increasing the membership of society/collection centers.

The MIS task force also presented the time schedule to complete this work in most efficient way, beginning with complete system analysis of present system, summarized in a study report for presenting to top management for reviewing and approval, system designing and implementation.

The managing director was satisfied with the presentation and gave his approval to go ahead but also asked them to go strictly by the time schedule to complete this project. He further asked the committee members to design the system in such a way that in future it can be integrated with processing of milk, inventory of finished milk products, marketing and distribution of products etc. He further recommended that written communication may be sent to all the concerned staff members regarding project description and to help them in conducting the system analysis of milk procurement and billing system. The project description is given below:

A.4 Project Description

A.4.1 Project title

System analysis study of milk procurement and billing systems (MPBS).

A.4.2 Project objectives

∑

To

identify the problems faced by staff and members of the society/collection

centre.

∑

To

evaluate the economic and technical feasibility of a new milk procurement and

billing system.

A.4.3 Approach to be taken

∑

Interview

the concerned staff and members of society/collection centre.

∑

Analyze

inputs, methods, procedures, data registers/files, outputs and internal

controls of the current system.

∑

Identify

and evaluate alternative systems.

∑

Prepare

recommendation and present Final survey report to top management.

A.4.4 Potential system benefits

∑

Reduce

the time and percentage of error in bill processing, this improvement in

customer service may enable the plant to increase the quantity of milk

procurement.

∑

Timely

generation of MIS reports will help manager to take immediate decision.

∑

Computerization

will improve work efficiency.

∑

Provide

an efficient MPBS as basic module to an integrated network system encompassing

billing, monitoring of technical input services, marketing, processing,

Inventory of finished milk products etc.

A.4.5 Schedule and efforts required

∑

Start

date.

∑

Expected

completion date.

∑

This

project will require two full time system analysts for seven weeks.

Approved by: Managing director.

A.5 Structured Systems Analysis

As indicated in introductory investigation, the managing director desires to have new milk procurement and billing system integrated with other areas. Basically, the MPBS would be designed to interface effectively with milk processing, finished milk product inventory, marketing of products, inventory of engineering spare parts etc. These systems must take second priority since they require data from the MPBS. Though these systems could be partially designed concurrent with the design of MPBS, but the current number of MIS department personnel is insufficient to undertake the simultaneous development of all systems. Overall, the new MPBS is to be the initial major module or building block for adding new integrated system later.

A structured approach to systems analysis of present MPBS involves analysis the highest-level data processing activities at central level as well as detailed activities at the society/collection centre and chilling centre level. This means that analyze all processing activities that have bearing on MPBS. Exceptions, irregularities and problems in procurement and billing are also noted for analysis. In turn milk procurement and bill processing activities are analyzed in a top-down manner that permits functional decomposition of procurement and bill processing modules to the lowest level.

A functional decomposition approach allows system analysts to examine both the functional activity and data aspects of procurement and billing system from the highest level to the lowest level. This approach provides a means of identifying inputs, constraining factors, and control information which affect procurement processing activities and outputs. As such functional decomposition provides a means for the system analysts to understand the present milk procurement and billing system. Functional decomposition diagram and context level data flow diagram representing the existing milk procurement and billing system is shown in figure 11.3 and 11.5 respectively in lesson 11. Finally, functional decomposition provides an effective basis for comparing the new MPBS system to the present one. This approach, then, plays an integral part in the detailed and concluding investigation of system analysis.

A.5.1 Detailed investigation of present MPBS

In order, for the MIS task force to comprehend what become apparent in the milk procurement and billing system, there is need for a detailed investigation using a structured approach. This includes the following modules:

∑

Review

the present system and analyze inputs.

∑

Review

methods, procedures and data communications.

∑

Analyze

outputs.

∑

Model

the existing logical system.

∑

Undertake

other analysis and considerations.

Each module is covered in a sufficiently comprehensive manner to enable any knowledgeable reader to envision the scope of the milk procurement and billing system and the relationship of its detailed parts.

A.5.2 Organizational structure

The plant is managed by one managing director for its day to day activities. He is assisted by a team of directors (Technical Director, Procurement Director, Marketing Director and Administrative Director). For technical matters the plan is looked after by a chairman appointed by the board of directors of the plant. An organizational chart of dairy plant can be drawn.

A.5.3 Review the present system

Can be attached as Annexure.

A.5.4 Analyze inputs

The input data is generated at four levels as described below :

A.5.4.1 Level I : Society/collection centre

I. Society/collection centre.

II. Membership data.

III. Requirement of stationary/equipment/chemicals etc.

IV. Requirement of technical input aids (indents). .

V. Data of milk quality & quantity received from members.

VI. Distribution of technical input material.

VII. Beneficiariesí details.

VIII. Truck sheet data (i.e. composite milk statement) dispatched to chilling centre/main dairy.

IX. Expenditure data on society/collection centre.

X. Revenue generated through the sale of technical input services.

A.5.4.2 Level II : Chilling centre

I. Statement of milk received (include quantity & quality parameters).

II. Statement of milk despatched.

III. Expenditure incurred on chilling centre.

IV. Transportation data.

A.5.4.3 Level III : Main dairy

I. Statement of milk received at dock yard.

II. Expenditure data for maintaining the procurement section.

III. Expenditure on technical input services.

IV. Transportation data.

V. Expenditure on equipment/chemicals etc.

A.5.4.4 Level IV : Management

I. Milk and transportation rates are decided by the management.

II. Other policy matters.

A.5.5 Methods, procedures and data/document transfer communication

Major source of transferring data/documents between society/collection centre and main dairy is the transport vehicle. All kind of requirements indents, statements are passed on to main dairy through vehicle at the time of collection of milk in morning/evening from society/collection centre. Description of document flow is as follows.

The milk compiled statements of milk received at collection centre/society is transferred to chilling centre. If the society/collection centre is nearby main dairy then these can be passed directly to main dairy. The indents for technical input services required and expenditure statements are also passed on to main dairy. From the main dairy dockyard milk is passed on to processing section and other statements are passed on to milk procurement section. Milk statements are sent to account and bill section where the draft alongwith details are generated and drafts are issued for the society/chilling centre, those who have supplied the milk at dock yard. The societies which supplied the milk at chilling centre, are paid by chilling centre based on the milk received at chilling centre. Further the farmers are paid by the societies/collection centers. The milk rate is decided by dairy management. The indents for technical input services are processed by procurement section and material is supplied to the societies/collection centers. The daily statement of milk received, procurement cost analysis, and transportation cost analysis etc. is also prepared as and when required by managing director/management.

A.5.6 Analysis of output -Various outputs generated at different levels are as follows:

A.5.6.1 Level 1 : Account and bill Section

- Payment detail for chilling

centre & collection centre/societies

No. & Name of society/collection centre/chilling centre : Date :

---------------------------------------------------------------------------------------------------

Date Time Milk type Quality Qty Fat% SNF% Rate/litre Amount

---------------------------------------------------------------------------------------------------

.

.

---------------------------------------------------------------------------------------------------

Total

---------------------------------------------------------------------------------------------------

Total Fat in kg =

Total SNF in kg =

- Bills

for private contractors (if any) in same format as above.

A.5.6.2 Level 2 : Main dairy reception dock yard

- Daily statement of milk

received

:

Date :

---------------------------------------------------------------------------------------------------

Date Time Chilling Society/Collection Quality Qty Fat% SNF%

Centre No. Centre No.

---------------------------------------------------------------------------------------------------

.

.

---------------------------------------------------------------------------------------------------

Average

---------------------------------------------------------------------------------------------------

Total

---------------------------------------------------------------------------------------------------

A.5.6.3 Level 3 : Procurement section

i). Total milk received route wise in a

specific period.

Milk procured route wise for the period:_____________to ______________

----------------------------------------------------------------------------------------------------

Route Type of Fresh Sour Curdled Total

No. milk Qty Fat% SNF% Qty Fat% SNF% Qty Fat% SNF% Qty Fat% SNF%

-----------------------------------------------------------------------------------------------------

.

.

----------------------------------------------------------------------------------------------------

Total

-----------------------------------------------------------------------------------------------------

ii). Cost analysis statement for the

period_____________to ______________

---------------------------------------------------------------------------------------------------

Route Quantity Fat% SNF% Procurement Transportation Chilling

No. cost/lit centre/lit cost. lit

---------------------------------------------------------------------------------------------------

.

.

---------------------------------------------------------------------------------------------------

Total

--------------------------------------------------------------------------------------------------

iii). Summery statement of important

activities performed under technical input aid program in a given period

Activity Name : Cattle feed/fodder Seed/Vet. Medicine/AIS

---------------------------------------------------------------------------------------------------

Soc./C.C. Name No. of beneficiaries Qty/No. Amount Subsidiary

No. Given

---------------------------------------------------------------------------------------------------

.

.

---------------------------------------------------------------------------------------------------

Total

---------------------------------------------------------------------------------------------------

iv). Bills for transport contractors

Transport contractor name:

Period :____________to_____________

Vehicle No. : Vehicle name :

---------------------------------------------------------------------------------------------------

Date Time Route No, Distance travelled Amount

---------------------------------------------------------------------------------------------------

.

.

---------------------------------------------------------------------------------------------------

Total

---------------------------------------------------------------------------------------------------

A.5.6.4 Level IV : Chilling centre

Bills for societies/CC in the same format as in level 1.

A.5.6.5 Level V : Society/collection centre

Payment details for members same format at level 1.

A.5.7 Model of the existing logical system

Based upon detailed investigation of existing milk procurement and billing system just completed, students are advised to draw data flow diagram. It should be noted that neither the equipment nor the type of manual and computer processing are shown in this diagram. The total concentration should be on the logical flow of data. All data needed in above processing steps serve as a basis for developing model of the system and data dictionary.

A.5.8 Undertake other analysis and consideration

The dairy plant is in a sound financial condition. It is noted for its strong management and its high profit. It is highly regarded in the society and is procuring more than 50% of milk production from the procurement area. Overall, the plant committee management is strongly committed to help the company move ahead. Because the plant has sufficient resources, it can adopt a new technology to remain in the competition with the other plants. Therefore, the Managing Director and MIS steering committee have agreed to computerize the activity without going into the details of exact or estimated returns from this project (in terms of amount). Just to improve the quality of services for its members of the societies/collection centers.

A.6 Concluding Investigations

A.6.1 Context diagram of MPBS

The working of entire system is depicted in one data flow diagram, i.e., context diagram in fig. 6.4. (in lesson 6). This diagram gives little detail and shows only the overview of the system. Detailed DFD can be drawn further for each component.

A.6.2 Volume of data

The volume of data varies according to the area covered for milk procurement and the number of farmers supplying the milk to the society/collection centers which varies from time to time. The plant under study is procuring milk from approximately 900-1000 societies/collection centers and each society/collection centre has 200-500 members and milk is procured once a day in the morning. Thus the number of transactions per day will be up to 500,000 per day, which is a very high volume application. Beside this there will be thousands of entries related to expenditure on technical input aids, number of AIs performed, detail of sale of fodder seeds, cattle feed, details of collection centers/societies, chilling centers and transport vehicles, etc.

A.6.3 Feasibility study of new MPBS

Now that each area of the present MPBS has been carefully analyzed, a feasible set of MIS alternatives must be developed in order to select the best one we will examine the following area before selecting the best feasible MIS solution:

A.6.4 Financial feasibility study

After discussing the matter with MD, it was found that dairy in good financial health therefore finance will not be any problem at all. The management wants a solution to be effective and beneficial to milk producers.

A.6.5 Social feasibility study

During discussions held with sectional heads of procurement and accounts, they shown keen interest in developing and implementing new system and extended their full support. Users of the system like operational staff at doc yard, field staff at society level and other were cordial and ready to contribute in developing and implementing the system since new system will save lot of time in preparing bills and reducing errors.

A.6.6 Technical feasibility study

Based on an analysis of the existing logical system of the MPBS and available hardware technology, MIS task force has identified the following basic MIS alternatives:

A.6.7 Centralized data processing

One powerful computer server with latest specifications with 8-10 terminals with windows network system connected through LAN, and high speed line/ laser printer will be installed in the main dairy plant. All data records will be transferred to the main computer centre from collection centre. Data entry & further processing will be made on the main computer system and bills may be prepared and distributed to society for further distribution to members. One/ two automatic milk collection units will also be required at central dairy to automatically feed the quantity and quality parameters into computer.

∑

Cost

: The cost will be around Rs. 10-11

lakh including high speed line printer.

Cost involved in employing trained man power.

A.6.8 Distributed data processing with microcomputers at the user end

All societies may be given an automatic milk collection system equipped with milk analyzer, online weighing balance connected with PC and GUI based software installed on PC to carry out all activities ate collection centre. In this case, data (Member ID, Quantity, Fat%, SNF%, etc) is entered automatically without human intervention. Price of milk will also computed automatically based on quality parameters and bills can be generated immediately. All processing will made at society level. In this case, at central level bills will be generated only for society/ collection centers not for individual members.

∑

Cost

One complete automatic milk

collection units costs around 1.5 Lakhs which includes computer and printer and

necessary software

∑

Benefits

and disadvantages of both approaches are discussed in table A.1

∑

Comparison

of current manual system with computerized systems on certain parameters is

shown in table A.2.

Table A.1 Benefits / disadvantages and cost of each feasible MIS alternatives

|

Type of Systems |

Benefits |

Disadvantages |

|

Centralized data processing

|

Limited trained man power is required to complete the job. |

Duplication of work at society & chilling centre level. |

|

Supervision of work is easy at one place. |

Data communications. |

|

|

Maintenance of CS will not be difficult at one place. |

More powerful computer system is required at the centre. |

|

|

More applications of dairy plant may also be taken up. |

If the main computer is down then whole work will be stopped |

|

|

Distributed data processing |

Each society will have full control over activities to be performed at society level |

Costly solution |

|

Data will be entered automatically and bill can be generated immediately |

Trained manpower required at each society |

|

|

This will reduce the burden of data entry at central level. |

Some societies may not be able to perform up to the mark. |

Table A.2 Comparison table of current MPBS with feasible MIS alternatives

|

Sl. No. |

Options |

Current System |

Centralized data Processing |

Distributed data processing |

|

|

1 |

Time taken in bill generation(days) |

8-9 |

2-3 |

Same day |

|

|

2 |

Data communication |

Transport |

Transport |

Not required |

|

|

3 |

% of errors in payment statement |

5 |

<5 |

<5 |

|

|

4 |

Time taken in solving disputes over payments(days) |

7 |

2 |

Immediately |

|

|

5 |

Trained manpower required (This includes system analysts, two programmers, two console operators, 8-10 data entry operators) |

Nil |

15 |

Nil |

|

|

6 |

Capability of processing data if main computer is down |

Not Applicable |

No |

Yes |

|

|

7 |

Capability of providing wide range of facilities |

No |

Yes |

Yes |

|

|

8 |

Initial cost (in lakhs) |

Nil |

10-12 |

1.5 Lakhs for each society |

|

|

9 |

Software development |

Nil |

In house |

Ready made |

|

A.7 Final Survey Report

The MIS task force with the assistance of the MIS user group prepared final survey report summarizing their findings to the MIS executive steering committee.

A.7.1 MPBS in brief

The dairy plant procures the milk from the societies or by setting up collection centers at the village level. Some private agents also supply the milk directly at dock yard. The milk is tested for quality and quantity at collection centre, chilling centre and at the dock yard of main dairy plant. Route network is designed by the procurement officer to collect the milk from societies/collection centers and transport vehicle is hired on contract basis to transport milk. Payment is made to members according to details entered in the pass book at the time of milk collection. Similarly societies/collection centers and chilling centers are paid on the statements of milk received at chilling centre/main dairy. If there is delay in transporting the milk then suitable deduction is made from his payments.

Dairy plant also supplies the subsidized cattle feed, fodder seed, veterinary aid, A.I. assistance and other technical input services/aids to enhance the milk production. Periodically the management is interested to know the cost of milk procurement/ transportation/ chilling per liter of milk, daily average milk procured route wise, average Fat% and SNF%, handling losses etc. The management is also interested to know the expenditure incurred on technical input services and the no. of beneficiaries. Bills are also to be generated periodically for payment to farmers against the milk supplied. The whole process is very time consuming and complex.

A.7.2 Major problems found in the system

The major problems found in the present system are described as follows:

∑ First major requirement of MPBS is to reduce the time period in generating bills by improving internal processing of data. This will also help in reducing errors in bill.

∑ Second major problem is that of errors in testing of milk at the society/collection centre level, chilling centre level and main dairy dock yard.

∑ Third major problem is data communication. Physically the data is moved through the transport vehicle. Therefore the data reaches the destination either at the end of day or on the next day. So a lot of time is wasted in data communication.

∑ Fourth major problem is time taken in solving the disputed cases of payment among societies, chilling centers and main dairy plant.

A.7.3 Redefined objectives

∑ The basic objectives of the new milk procurement and billing system will be :

∑ Timely generation of bills and payment to milk producers.

∑ Timely solution of disputed cases over payments.

∑ To determine handling losses.

∑ Cost analysis to monitor the performance of milk procurement.

∑ Monitoring of technical input services.

A.7.4 Main benefit expected from new MPBS

∑ Error free and prompt generation of bills for payment to milk producers.

∑ Prompt reply to queries regarding daily procurement of milk.

∑ Ability to analyze the procurement, chilling and transportation cost etc.

∑ Easy determination of procurement losses.

∑ Ability to calculate expenditure incurred on technical input services/aids.

∑ Easy to calculate the commission paid to societies.

∑ Prompt reply to the queries of management from time to time.

∑ Improvement in the quality of service.

∑ Better quality work by producing legible outputs.

∑ Ability to reprocess the data without much extra efforts.

A.7.5 Recommendations

∑ The report concluded with the following recommendations for management approval:

∑ Immediately computerize the activity to at society level to generate bills well in time with minimum errors.

∑ Authorize the MIS task force to proceed with the design phase of new MPBS,

∑ Develop new with distributed data processing.

∑ Outputs may be designed in consultations with users and officials.

∑ Continue to examine the feasibility of other related fields of dairy plant like milk processing, inventory of finished milk product, marketing of milk etc.

∑ Automatic machines may be provided to all the societies/collection centres to weigh and test the quality of milk.

Upon listening to an oral presentation of the foregoing recommendations by MIS task force, MIS executive steering committee concurred with all recommended items. The executive committed observed that there is a lot of difference in the cost of feasible MIS alternative cases. But the efficiency wise distributed processing system is more effective.

MIS task force next met with the managing director to present their final report. Having been kept informed of the project status by the MIS executive committee, he was well prepared to discuss and review their recommendations. He was very much satisfied with the progress made by the MIS executive steering committee and MIS task force in the project. He also thanked all the members for taking keen interest. Further he assured that within one week you will get the final approval to proceed with the next step.