Module 4. Microbiological methods of milk testing

Lesson 16

DYE REDUCTION TESTS

16.1 Introduction

As already said in lesson 15, the microbiological quality control testing of milk can be divided into two different groups: for example ‘direct tests’ (quantitative) and ‘indirect tests’ (qualitative). Here we shall be discussing the qualitative tests of milk in detail.

16.2 Methylene Blue Reduction Test (MBRT)

The methylene blue reduction test is based on the fact that the color imparted to milk by the addition of a dye like methylene blue will disappear more or less quickly. The removal of the oxygen from milk and the formation of reducing substances during bacterial metabolism cause the color to disappear. The agents responsible for the oxygen consumption are the bacteria. Though, certain species of bacteria have considerably more influence than others, it is generally assumed that the greater the number of bacteria in milk, the quicker will the oxygen be consumed, and in turn the color will disappear. Thus, the time of reduction is taken as a measure of the number of microorganisms in milk. Although, it is likely that it is more truly a measure of the total metabolic reactions proceeding at the cell surface of the bacteria. The test is useful in assessing the bacteriological quality of milk by determination of the time taken for the reduction of methylene blue in milk indicated by its colour change.

16.2.1 Principle

Oxidation reduction potential of a substrate may be defined generally as the chemical process in which the substrate either loses or gains electrons. When an element or compound loses electrons the substrate is said to be oxidized, while a substrate that gains electrons becomes reduced.

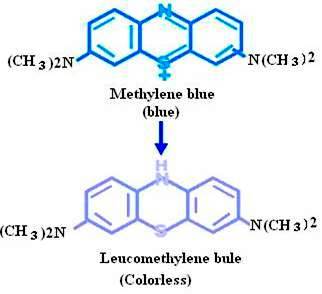

Milk, as it exists in the udder has a sufficiently low redox potential to reduce the methylene blue immediately. The processes like milking, cooling, dumping etc. raise the oxidation reduction potential of milk to +0.3V, because of the incorporation of atmospheric oxygen. At this particular O-R potential, methylene blue is in oxidized state. When bacterial cells multiply in milk these, consume dissolved oxygen and as more and more oxygen is used and gets depleted, the dye starts acting as electron acceptor instead of oxygen. As the oxidation reduction potential decreases from + 0.06 to – 0.01 V, methylene blue gets reduced. One atom of hydrogen is taken up by the double bonded nitrogen of the dye that converts it into colourless state. The greater is the number of microorganisms in milk, the greater is the metabolic activity and the faster is the reduction of methylene blue.

Fig. 16.1 Conversion of methylene blue to leucomethylene blue

MBRT is a rapid, sensitive and low cost, yet a simple quantification method to evaluate viable count during a growth experiment. It is widely used in dairy industry to determine the microbial load in the milk. This test involves the addition of methylene blue into a milk sample and measuring the time required for decoloration. The disappearance of color in a short time indicates a high microbial load. The disappearance of color is due to the removal of oxygen from milk and formation of reducing substances during bacterial metabolism.

Methylene blue in a sample containing microorganisms gets reduced to dleukoT or colorless form of the dye at the cell surface via reductase enzymes present in the cell membrane. This colorless form of methylene blue is uncharged, lipophilic, and enters cells by diffusion across the plasma membrane, where it is re-oxidized and thus sequestered within the cells. If oxygen is available, reduced methylene blue can be oxidized by the mitochondrial electron transport system that will result in the reappearance of the blue color.

Although the exact mechanism of dye reduction is not clearly known, some reports available suggest that MB is reduced by transmembrane reductases. This mechanism is applied to evaluate the microbial load in a liquid medium. The shorter time required for the disappearance of the blue color is indicative of a higher microbial load. It is assumed that greater the number of microorganisms, more the oxygen demand and lesser the oxygen concentration in medium resulting in the faster disappearance of the color. This fact has been used as a broad indicative test of a microbial load representing microbial quality of milk.

16.2.2 Standard solution of methylene blue

One tablet of methylene blue thiocyante or chloride is dissolved in 200 ml of cold sterile glass distilled water by gentle heating to facilitate dissolving and then add another 600 ml distilled water.

16.2.3 Procedure

The samples of milk are mixed thoroughly. If the milk is in a bottle/ sachet, it shall be inverted at least 25 times to mix the fat uniformly with the milk. Take 10 ml of milk into a test tube and add 1 ml of standard methylene blue solution. Invert the test tube to mix the milk and methylene blue solution. Place the test tube in a thermostatically maintained water bath at 37±0.5°C and note down the time of incubation. Observe the test tubes after 30 min for decolourization reduction of dye. If there is no decolourization the tubes are inverted once and transferred to the water bath for further incubation. After 30 min, continue to observe for the reduction of dye at an interval of every one-hour. The milk shall be regarded as decolorized, when the entire column of milk is completely decolorized or is decolorized up to 5 mm of the surface.

16.2.4 Grading of milk

The quality of raw milk is adjusted by making the following observations

Table 16.1 Grading of milk based on MBRT as per BIS standard

|

MBR Time (hr) |

Quality of raw milk |

|

5 and above |

Very good |

|

3 and 4 |

Good |

|

1 and 2 |

Fair |

|

1/2 and below |

Poor |

Table 16.2 Grading of milk in MBR test

|

Quality of milk |

Reduction time |

Approx. keeping quality/ml |

Approx. bacterial count per ml |

|

Good |

5 ˝ hour or more |

40 hrs |

Below 5,00,000 |

|

Fair |

2 to 5 ˝ hours |

30 hrs |

5,00,000 to 40,00,000 |

|

Bad |

20 minutes to 2 hrs |

10 hrs |

40,00,000 to 2,00,00,000 |

|

Very bad |

20 minutes or less |

Less than 10 hrs |

Above 2,00,00,000 |

16.2.4 Factors affecting the MBRT

These are factors that affect the MBRT and therefore, the steps of operation should be uniform.

1. Since, the oxygen content must be used up before the colour disappears; any manipulation that increases the oxygen content affects the test.

a. Cold milk holds more oxygen than warm milk

b. Pouring milk back and forth from one container to another increases the oxygen, and

c. During milking time much oxygen may be absorbed.

2. The rate of reduction of dye depends on the type of microorganism

a. Coli forms appear to be the most rapidly reducing microorganisms,

b. Closely followed by Lactococcus lactis spp. lactis, some of the faecal Streptococci, and certain micrococci.

c. Psychrotrophs reduce methylene blue very slowly.

3. Presence of a large number of leucocytes as in mastitic milk will affect the reduction time materially.

4. Light hastens reduction process and therefore, the tests should be carried out in relatively low light.

5. Concentration of dye should be uniform as an increased concentration lengthens the time of reduction.

6. Increasing the incubation temperature augments the activity of the bacteria and therefore shortens the reduction time.

7. Creaming of milk causes a number of micro-organisms to be removed from of milk and brought to the surface with the rising fat. This factor causes variations in the reduction time, since the bacteria are not evenly distributed.

8. The accuracy of test is increased, reduction time shortened and decolourization more uniform, if the samples are periodically inverted during incubation.

16.3 Resazurin Reduction Test (RRT)

Resazurin reduction t is another method of dye reduction test and the principle of this test is nearly similar to methylene blue reduction test. In MBRT the time for reduction of the dye is measured, while in RRT, at a fixed period time, specific shade of colour and its intensity is measured. There are two variations in RRT of testing milk. One is 10 min RRT test that can be used as a rapid platform test for quick assessment of milk at the raw milk reception dock. The other one is a one hour RRT performed in the lab.

16.3.2 Principle

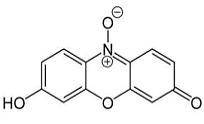

Unlike methylene blue the resazurin undergoes reduction through a series of colour shades viz., blue, purple, and lavender, pink before completely getting reduced to colourless. Resazurin dye which is blue in colour at the oxidation-reduction potential of + 0.3 volts undergoes an irreversible change to pink colour compound (resorufin) when the redox potential reduces to +0.2 volts. When the redox potential is reduced further to + 0.1 volts or less, the colour of dye changes to colourless (dihydroresorufin), which is a reversible reaction. Usually, the degree of reduction of the dye is measured after a fixed time of incubation of milk sample in the presence of dye. The reduction of dye to a particular shade of colour is dependent upon the extent of depletion of oxygen by metabolic activity of microbes. The colour change is measured with the help of a Lovibond colour comparator and a standard resazurin disc.

16.3.3 Standard solution of resazurin

One tablet of Resazurin is dissolved in 50 ml of cold sterile glass distilled water by gentle heating to facilitate the dissolving. This is the bench solution for direct use and should always be used as fresh.

Alternatively dissolve 0.05 g of resazurin powder in 100 ml of distilled water and boil the contents for 30 min. This will make a standard solution of 0.05%, which should always be kept in a cool and dark place, stored in an amber coloured bottle. The bench solution (0.005%) for regular use should be prepared freshly by diluting the standard solution with distilled water i.e. 1 ml of standard solution with 10 ml of distilled water.

16.3.4 Procedure

· Take 10 ml of milk into a test tube and add 1 ml of working solution of Resazurin solution.

· Put air tight closure to prevent oxygen entry

· Invert the test tubes to mix the milk and Resazurin solution.

· Place the test tubes in a thermostatically maintained water bath at 37 ± 0.5 °C and note down the time of incubation (10 min or 1 h).

· At the end of incubation match the colour of the milk with one of the colour standards of Resazurin disc.

16.3.5 Resazurin chemical structures

Fig. 16.2 Resazurin

Resazurin (7-Hydroxy-3H-phenoxazin-3-one 10-oxide)

Fig. 16.3 Resorufin

Resorufin (7-hydroxy-3H-Phenoxazin-3-one, sodium salt)

16.3.6 Grading of milk

The quality of raw milk is adjusted by using the following parameters.

Table 16.3 Grading of milk based on RRT as per BIS standard

|

Resazurin disc No |

Quality of milk |

|

4 or higher |

Good |

|

3˝ to 1 |

Fair |

|

˝ and below |

Poor |

Table 16.4 Grading of milk by resazurin test

|

Disc no. |

Colour |

Bacterial quality of milk |

|

6. |

Blue |

Excellent |

|

5. |

Lilac |

Very good |

|

4. |

Mauve |

Good |

|

3. |

Pink mauve |

Fair |

|

2. |

Mauve pink |

Poor |

|

1. |

Pink |

Bad |

|

0. |

White |

Very bad |

16.3.7 Advantages of dye reduction test

· Used for estimating the suitability of milk for liquid consumption.

· These tests are cheaper and less time is required.

· In case of SPC, clumps of microbes are recorded as one colony, whereas the rate of decolorizing of dye is due to the combined metabolic effect of each bacterium in the clump.

· With the help of these tests the activity is measured rather than the number of bacteria.

· Unlike the artificial media used in SPC, in milk the natural environment for microbes is present.

· In case of RRT, the results can be measured in a shorter time.

· Some of the bacteria capable of reducing the dye may not develop colonies on the medium used in SPC.

16.3.8 Disadvantages

· Rate of reduction of dye varies considerably and is related to species and the rate at which different micro-organisms grow at a particular temperature.

· Inhibitory substances like penicillin and other antibiotics prevent the growth of bacteria and thus increase the reduction time.

· Not suitable for classifying milk with low bacterial counts of less than 105 /ml.

· Reduction capability may vary because of variation in proportion of bacteria carried into cream layer by the rising fat globule.

· These tests do not give indication for the type of micro-organisms present.

· Temperature of incubation used during these tests is not the optimum for majority of the micro-organisms present in milk.

· Not suitable for testing quality of pasteurized milk intended for processing because of the low number of micro-organisms.

· Require continuous attention until reduction takes place.