Module

4. Tomato and tomato based products

Lesson 21

TOMATO JUICE

EXTRACTION AND JUICE CHARACTERISTICS

21.1 Introduction

Tomato (Lycopersicum esculantum) belongs to family Solanaceae. Tomato is one of the most popular and widely grown vegetable crops in the world. It stands next only to potato in terms of production. India is fourth largest producer of tomato next only to China, USA and Turkey with an estimated production of 11.98 million tonnes in 2010. In India, Bihar is the leader in terms of area under tomato crops, but Uttar Pradesh leads is production as well as productivity. It is short duration vegetable crops which fit suitably among different dropping system. Important cultivars of tomatoes grown in India include Pusa ruby, Pant bahar, Pusa hubrid-1 & 2 and Arka Saurabh.

Tomato is a very versatile vegetable for culinary purposes. Ripe tomato fruit is consumed fresh as salads and utilized in the preparation of a large number of processed products such as puree, paste, powder, Ketchup, sauce, soup and canned whole fruit. The partially ripened fruits are processed into pickles, chutney and in the recipe of number of traditional cuisines.T he waste obtained after the juice or pulp extraction i.e. seeds and pomace is also utilized for the extraction of tomato seed oil and lycopene, respectively.

21.2 Composition of Tomato

Chemical composition of tomato depends on various factors such as variety, growing environment and package of practice. Besides it, the composition may also vary at different stage of maturity. The composition of tomato is important from the quality point of view as it affects colour, nutrient content, flavour and texture of the both raw as well processed tomato.

Table 21.1 Composition of tomato at different stages

|

Variable |

Green (Mature) |

Red |

Red (Ripe) |

|

Total Solids (%) |

6.4 |

5.8 |

5.2 |

|

Titratable Acidity (%) |

0.29 |

0.27 |

0.29 |

|

Ascorbic Acid (mg/100g) |

14.5 |

23 |

22 |

|

Starch (%) |

0.61 |

0.18 |

0.07 |

|

Reducing Sugar (%) |

2.4 |

3.45 |

3.65 |

|

Pectin (%) |

2.34 |

1.74 |

1.62 |

|

Lycopene (mg/100g) |

8 |

374 |

412 |

|

β-Carotene (mg/100g) |

50 |

10 |

0 |

|

Protein Nitrogen (mg/g dry wt.) |

9.44 |

10.27 |

6.94 |

Chemical composition of tomatoes varies at different stage of maturity. Total solid content decreases with maturity from green (mature) to eating ripening maturity due to the conversion of insoluble components mainly starch and insoluble polysaccharides into simple sugars and soluble polysaccharides, respectively. Soluble solids in tomato mainly consisted of sugars, which play significant role in flavour development. The chlorophyll content decreases with concomitant increase in the concentration of lycopene, the major pigment in tomato. The concentration of β-carotene lowered during the maturity and its concentration is more in pink & yellow coloured varieties than red varieties.

Pectin a major cell wall constituent is important for the firmness of fresh tomato and influence the consistency of tomato products. However, the concentration of soluble pectin increased during the ripening because of the higher pectinolytic acidity. Acidity of tomato is mainly attributed to their citric and malic acid content. The average calorific value of tomato varies in the range of 23-25 Kcal/100 g, which is quite low. However, the higher amount of antioxidants like lycopene and ascorbic acid further enhance their nutritional value. They are also very good source of minerals specially magnesium and potassium which have heart healthy role. They also supply copper, iron and sulphur in diet. Oxalate is considered as anti-nutrient component in tomato which may be responsible for stones in kidney and gall bladder by complexing calcium in gastrointestinal lumen. Thus it also decreases the bioavailability of calcium in body.

21.3 Nutritional and Therapeutic Effects of Tomato & Tomato Products

Tomatoes are good source of ascorbic acid, which constitutes about 15-20 mg per 100 g of edible parties. The level of ascorbic acid increases with ripening. The concentration also depends on the cultivar and exposure to sunlight. One of the most widely researched components is lycopene, a reddish colour pigment, responsible for characteristic colour of tomatoes. Lycopene is the most effective singlet oxygen scavenger in biological system. Vitamin C, lycopene and carotenoides present in tomatoes are effective antioxidants and have been found effective in prevention of number of cancers. Lycopene also exhibits similar effectiveness in inhibiting low density lipoprotein oxidation as b-carotene.

21.4 Tomato Pulp and Juice Extraction

Tomato juice and pulp are the major primary processed products of tomato which may be utilized for the production of high value added products like puree, sauce, ketchup, chutney, powder etc. All varieties of tomato are not suitable for processing point of view. The varieties which are used for juice and pulp manufacture must possess following characteristics.

- Deep red coloured varieties are preferred as yellow coloured pigments not only mask the red colour in

processed tomato products but these are also susceptible to oxidation

resulting in brown colouration.

- Firm but ripe fruits

should always be used as they contain sufficient amount of pectin which is

essential for the consistency of the finished products like puree, sauce,

ketchup etc.

- Green coloured and sour varieties should not be used as they

will affect the flavour and colour of the resultant products.

- Tomatoes are also

susceptible to microbial decay, hence any

infected or diseased fruit should never be used for the manufacture of

products as they may pose health hazards.

Fig.

21.1 Tomato’s suitable for pulp extraction

21.4.1 Preliminary processing of tomato

After selection of suitable fruits, they are washed in running water to remove all adhering dirt, dust, foreign particles including fungal filaments and other microbes. On large scale production plant, rotary washers or trough washers flitted with moving conveyer belt and soft rubber brushes are generally employed.

21.4.2 Trimming & sizing

Tomatoes are trimmed manually with the help of knife to remove green, yellow coloured portion, decayed or infected parts and stalks. The trimming losses may vary from 4 to 17% depending on the selection of raw material. After trimming, tomatoes are cut into 4-6 small pieces of 0.4-0.6 inch and crushed for juice extraction.

21.4.3 Pulping or juice extraction

The tomato juice is probably one of the most widely used juices. Fresh raw tomato juice is most beneficial and because of its alkaline reactions if consumed alone. However, presence of sugar and starch rich foods along with tomato juice make is acidic. The juice extraction may be done either by hot pulping, or cold pulping method.

21.4.3.1 Hot pulping

Crushed tomatoes are boiled in their own juice in steam-jacketed stainless steel kettles or aluminum pans for 3 to 5 minutes to facilitate pulping. The crushed or chopped tomato pieces are heated to at least 82°C for 15-20 seconds to inactivate pectic enzymes. On industrial scale heating is usually carried out in rotary coil tanks followed by passing through a plate heat exchanger (PHE) and holding tube to achieve a processing temperature of 104°C to retain at least 90% of the potential serum viscosity in the original fresh tomato. At small scale crushed or whole tomatoes are pressure cooked for 2-3 minutes. Hot pulping or hot break method has following advantages:

· Serum separation tendency in the product is checked, because of more extraction of pectin present in skin and around the seeds. Heat treatment also inactivates the enzymes (pectic enzymes specially polygalacturonase) that may hydrolyze pectin and reduce the viscosity of the juice or pulp. Polygalacturonase is highly heat resistance enzyme that cause splitting of two adjacent galacturonic acid molecules and responsible for softening.

· Juice is quite viscous, heavy bodied and homogenous because of the extraction of pectin and other soluble polysaccharides.

· Thermal treatment partially sterilizes the juice or pulp; thereby it decreases the initial microbial load and product can be kept for longer period.

· Inactivation of oxidative enzymes i.e. ascorbic acid oxidase, prevent loss of vitamin C.

· More juice yield as compared to cold pulping.

· Juice or pulp obtained by hot pulping process is deep red and attractive in colour. It is because of the release of pigments located within the cell vacuoles due to heating.

21.4.3.2 Cold pulping

In cold pulping or cold break method tomatoes are scalded to facilitate the separation of skin before chopping. Tomatoes are crushed or chopped at temperature less than 66°C and allowed to fall into a holding tank, where they remain for few minutes. During this period the native cell wall hydrolyzing enzymes of pectinolytic enzymes of the tomatoes are liberated and catalyze the various hydrolytic reactions to release the cellular components. The cold break juice is better in terms of flavour, colour and nutrients mainly vitamin C, but the juice is quite prone to spoilage and quick processing of the extracted juice is necessary. However, following defects are found to be associated with this method:

· Extraction of juice from the interior of cell requires higher pressure. Hence often juice yield become low, higher pressure cause extraction at juice around the seeds, which is more acidic and less sweet.

· Inferior colour (lighter) because of the less extraction of pigments from the skin

· Poor microbiological quality as comparison to hot break juice.

· Less nutrition due to oxidation of vitamin C resulting in loss.

· Cold extraction results in insufficient extraction of pectin and other polysaccharides that may adversely affect the viscosity or consistency.

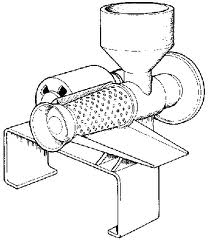

21.4.3.3 Equipments for pulp or juice extraction

Two different types of machines are used to extract the juice or pulp from the tomatoes namely Continuous spiral press and the Cyclone or pulper.

21.4.3.3.1 Continuous spiral press

The equipment consists of a long spiral screw which presses the tomatoes against a tapered screen of fine filter of 25 mesh size. The crushed tomatoes are fed through hopper and conveyed by the rotation of screw which normally rotates at a speed of 250 rpm. The low speed further disintegrate the tomatoes and free flowing juice and small pulp particles passed through the screen whereas skin and seeds are retained. During the extraction of juice or pulp care is taken to avoid incorporation of air and minimize the oxidative damage.

21.4.3.3.2 Cyclone or pulper

Juice can also be extracted by passing the crushed or chopped tomatoes through a cyclone or pulper. The machine consists of perforated cylindrical screen with apertures on about 25 mesh size and one rotating shaft which moves at very high speed to broken down the tomatoes into very small sized particles. The free flowing juice and smaller pulp particles are passed through the screen and separated out. In this method the insoluble solids in the juice are very finely divided and remain in juice for longer period. However, the use of cyclone results in incorporation of air which accelerate the various oxidative reactions.

In any method of juice or pulp extraction not more than 60% of fruit should be recovered as juice or pulp other it may affect the flavour and appearance of the resultant juice or pulp adversely.

Fig. 21.2 Schematic diagram of tomato pulper

21.5 Processing of Juice or Pulp

As per FSSA definitions thermally processed tomato juice means the unfermented juice obtained by mechanical process from tomatoes (Lycopersicum esculentus L) of proper maturity and processed by heat, in an appropriate manner, before or after being sealed in a container, so as to prevent spoilage. The juice may have been concentrated and reconstituted with water for the purpose of maintaining the essential composition and quality factors of the juice. The product may contain salt and other ingredients suitable to the product. The product shall be free from skin, seeds and other coarse parts of tomatoes. The product shall have pleasant taste and flavour characteristic of tomatoes free from off flavour and evidence of fermentation. The product shall conform to the requirements of total soluble solids (TSS) m/m free of added salt to be not less than 5.0 percent. The product may contain permitted food additives as specified by FSSA. The juice thus obtained is filtered to remove undesired portions like skin fractions, seeds by passing through filter (metallic or polymer vibrating perforated screen with desired pore size). The filtered juice is de-aerated immediately to prevent the oxidative losses. The additives or ingredients like sugar, citric acid or salt is added to improve the flavour of the juice. On an average juice should have TSS content of 5.66 per cent at 20°C. Juice may further be filled into bottles, cans using filling machine. The fill machines are adjusted to give minimum headspace as possible in order to check oxidative deteriorations. The cans are hot filled at about 82-88°C followed by processing at 121°C for not less than 0.7 minutes, followed by cooling of containers by spraying cold water jackets.

In case of pulp homogenization is suggested to retard the tendency of serum separation in juices and other processed products. Tomato juice or pulp is very much susceptible to spoilage by mould, yeast and bacteria. The pH of the tomato juice and pulp varies in the range of 4.0 to 4.4. The major risks of spoilage of from spore forming species other than Clostridium botulinum mainly Bacillus coagulans among the aerobes and Clostridium pasteurianum and Clostridium thermosachharolyticum among anaerobes. The spoilage of tomato juice is characterized by a peculiar off-taste and odour known as ‘flat sour”.