Module 8. Tea

Lesson 29

TEA LEAF PROCESSING

29.1 Introduction

The production of orthodox and CTC tea accounts for 52.0 and 48.0% of black tea production respectively. India is the largest producer of Black tea while China is the largest producer of Green tea in the world.

Most of the teas we buy are blends, mixed from different pure teas so as to ensure same flavour from year to year.

Leaf is more popular in northern India and Dust in Southern parts. Central India – equal consumption of both dust and leaf varieties.

29.2 Chemistry of Tea Leaves

The fresh tea leaf is characterized by large quantities of methylxanthines and polyphenols. The composition of unprocessed tea leaf and young shoot of Assam tea is presented in Table 29.1 and Table 29.2 respectively.

Table 29.1 Composition of unprocessed tea leaf

|

Constituents |

Percentage |

|

Protein |

20 |

|

Carbohydrates |

30 |

|

Lipids |

2 |

|

Polyphenols |

33 |

|

Caffeine |

5 |

|

Vitamins and minerals |

7 |

Table 29.2 Chemical composition of young shoot of Assam tea

|

Components |

Dry weight (%) |

|

A. Soluble in water |

|

|

Phenolics |

30 |

|

Flavanols* |

18-32 |

|

Flavonol glycosides |

3-4 |

|

Proanthocyanidins |

2-3 |

|

Phenolic acids |

|

|

- Caffeine |

3-4 |

|

Amino acids |

|

|

- Theanine |

2 |

|

- Others |

2 |

|

Carbohydrates |

4 |

|

Organic acids |

0.5 |

|

B. Partially soluble in water |

|

|

Starch |

2-5 |

|

Other polysaccharides |

12 |

|

Protein |

15 |

|

Ash |

5 |

|

C. Insoluble in water |

|

|

Cellulose |

7 |

|

Lignin |

6 |

|

Lipids |

3 |

|

Pigments |

0.5 |

|

Volatiles |

0.01-0.02 |

* Flavanols comprise of Epigallocatechin gallate: 9-13%, Catechin: 1-2%

29.2.1 Methylxanthines

Caffeine – a purine alkaloid. Its content in fresh leaf is about 3-4% (dry weight basis) which cannot be significantly reduced by conventional tea processing. High caffeine levels leads to good ‘cream’ formation in the liquor. Caffeine reacts with theaflavins and imparts ‘briskness’ to tea infusion.

29.3 Enzyme action

Polyphenol oxidase enzyme in tea leaf plays a key role in fermentation. Other enzymes include peroxidase, amylase, b-glucosidase, peptidase, chlorophyllase, phosphatase and leucine transaminase.

Catechins &

Polyphenol oxidase ![]() Gallocatechin

Theaflvins and Thearubigins

Gallocatechin

Theaflvins and Thearubigins

Enzymatic oxidation

Theaflavins and Thearubigins are the two groups of polyphenolic compounds unique to black tea. Theaflavins account for 0.3-1.8% of dry weight of black tea. They are bright red pigments which gives the liquor the highly sought-after characteristics (i.e. ‘brightness’ and ‘briskness’ (keen/sharp flavour)). Thearubigins comprise between 9-19% of the dry weight of black tea. They are phenolic brown pigments with acidic properties. Aroma forms during fermentation.

29.3.1 Polyphenols and Polyphenol oxidase activity

29.3.1.1 Green tea

The most important biochemical changes to occur during steaming or roasting are inactivation of the enzyme polyphenol oxidase so that the catechins remain unoxidized, preserving the green colour of the leaf.

29.3.1.2 Black tea

Fermentation is the most important stage in ‘black tea’ manufacture, which results in the formation of taste and aroma products, responsible for character of black tea. Fermentation is a misnomer, since microorganisms are not involved.

29.4 Tea Leaf Processing

The processing of tea leaves starts just after harvesting. The sequence of steps is as detailed below:

29.4.1 Harvesting/Plucking

This involves manual or mechanical removal of terminal young tender portions of peripheral shoots. The standard method is to pluck ‘two leaves and a bud’.

The quality of final product deteriorates with an increase in mature leaf content.

Hand plucking is preferred. The mechanical harvesting involves use of modified hedge trimmers and motorized machine pluckers.

29.5 Black Tea Processing

29.5.1 Withering

The change which occurs in green leaf from the time it is detached from the plant to the time of maceration or rolling is collectively referred to as ‘Withering’.

Air temperature, atmospheric vapour pressure, air velocity and air direction affects the rate and degree of physical wither.

Green leaves are spread over mesh in specially made wooden troughs with a bed thickness of 20 – 45 cm. A cross flow of heated air (temperature raised by 3-5oC by an electric fan) or ambient air during favourable atmospheric condition is maintained during entire stage (16-19 hours). This process reduces the moisture content from 80% to 50-60%.

It is a physical process wherein (a) moisture loss leads to changes in cell membrane permeability; the stomata on the lower surface of the leaf begin to shut gradually, (b) it preconditions the leaf for ‘maceration’ or ‘rolling’.

29.5.1.1 Two-stage withering

The leaf is stored in a holding tank with minimal moisture loss for about 6 h to achieve chemical wither. The leaf is then spread on withering troughs or a moving belt witherer and moisture is rapidly reduced by use of warm air.

Other methods include Drum withering, Tunnel withering, etc.

29.5.2 Maceration / Rolling

29.5.2.1 Orthodox method

The physically withered leaf is subjected to rolling. The leaf gets damaged, become twisted and the semi-permeable membrane of leaf gets distorted allowing the cell juices to be expelled to cover the leaf surface. This allows the juice to mix with cellular enzyme in presence of oxygen and the chemical reactions necessary for fermentation commences.

29.5.2.2 Cruch, Tea and Curl (CTC) method

The withered leaves are passed through CTC machine, causing severe rupturing of leaf cells. Machine consists of two steel engraved rollers rotating at different speeds in opposite direction (70 and 700 rpm). The leaves are allowed to consecutively pass through 2-3 such machines to achieve rupturing of cells and desired size.

The CTC machine has 3 sets of rollers: (a) first cut (coarse), (b) second cut (fine) and (c) third cut (super fine), after which the leaves are completely rolled. The capacity of CTC machine ranges from 750 to 1000 kg/h.

Other maceration methods include Legg-cut, Rotorvane, Triturator. A modern factory uses Rotorvane plus three CTC machines in series.

29.5.2.2.1 Advantage of CTC over Orthodox process

· Leaf distortion is much greater

· Fermentation is faster

· Liquoring properties are improved

· CTC and Lawrie Tea Processor (LTP – a modern CTC machine) teas have higher levels of theaflavins and thearubigins and therefore have more colour and are brighter and brisker than orthodox teas.

29.5.3 Fermentation

The liquor characteristics of black tea can be determined by control of temperature and time of fermentation (chemical transformation). The rolled leaf mass is placed on floor in thin layers at room temperature and with increased humidity (90-95% RH) using humidifiers. Fermentation is continued till the colour of leaf mass turns golden brown (1-2 hours).

Batch method uses troughs or trolleys, while Continuous method uses perforated moving belt fermentation machines through which air is passed.

The fermentors are connected to air supply by a duct, which can be humidified, if necessary, to reduce the temperature of fermenting tea (dhool).

The enzymatic oxidation, originally termed as ‘fermentation’ since it affects liquor quality and cuppage of tea. Such operation influences the colour, brightness and briskness of liquor. It also imparted mellowness to brew. After fermentation, the colour of leaf mass changes from green to bright coppery red. Generally, the lower the fermentation temperature, the better is the black tea.

29.5.4 Firing/Drying

Once optimum fermentation is achieved, it is necessary to destroy enzymes. The ‘dhool’ is fed to the driers by conveyors at a temperature of 90-120oC for 12-15 minutes. This process reduces the moisture content of fermented tea from ~ 60% to < 4%. It terminates fermentation by inactivating the enzymes. It makes the product fit for sorting and packaging.

In driers the inlet and outlet temperature may range from 82-98oC and 45-55oC respectively. Fluidized bed driers are being used recently. In this the blown hot air moves the dhool by process of fluidization. The disadvantage of firing is loss of considerable amount of volatile aroma compounds.

29.5.5 Grading and sorting

Tea after firing is a mixture of particles of different sizes, ranging from ‘dust’ to ‘leaf’ of about 5 cm long and 1.3 cm wide. They are sorted into uniform grades acceptable to the buyers. The grading and sorting of tea is carried out using mechanically oscillatory sieves fitted with meshes of many different sizes. Winnowing in some form or other is routinely employed and according to the size and density of the particles, separates ‘fannings’ and ‘dust’, carrying away the fibrous residues which is of no commercial value as a grade.

29.5.6 Packaging and storage

For bulk transport, Tea chests are used to contain 60 kg tea. Chest is made up of plywood, lined inside with Aluminium foil. Other packaging material includes multiwalled paper sacks – 2 plies of Kraft paper with an additional layer of Aluminium foil on the inside.

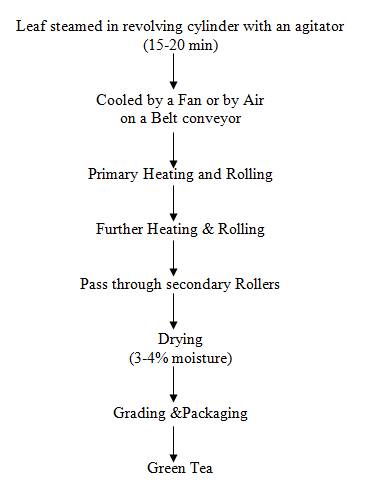

29.6 Green Tea Processing

It is manufactured from fresh leaf which has not been fermented. It depends on arresting the enzyme activity in green leaf. The different methods of green tea production are depicted in Fig. 29.1 and 29.2.

29.6.1 Chinese process of green tea manufacture

Fig. 29.1 Green tea processing by Chinese process

29.6.2 Japanese process of Green tea manufacture

Fig. 29.2 Green tea processing by Japanese process

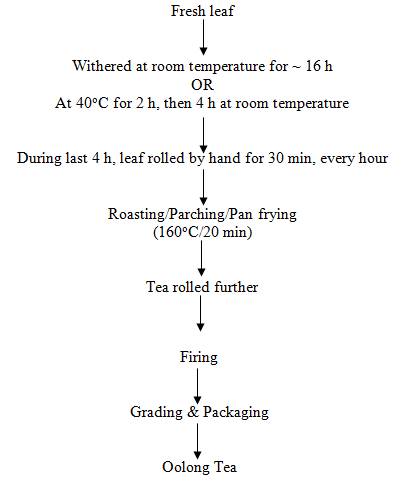

29.7 Processing for Partially Fermented Tea

The typical processing method adopted for preparing partially fermented tea is shown in Figure 29.3.

Fig. 29.3 Tea processing for partially fermented tea.

Varieties of Tea based on processing

|

Country |

Type of teas |

|

India |

Both orthodox and CTC |

|

China |

Green tea and orthodox tea for export |

|

Sri Lanka |

Mostly orthodox variety |

|

African countries |

Only CTC teas |