Module 10. Pickles and sauerkrauts

Lesson 35

TECHNOLOGY OF SELECTED PICKLES-I

35.1 Introduction to Fermented Pickles

As one of the oldest forms of food preservation, fermentation has played a key role in enabling people to survive periods of food shortage. Fermented foods originated several thousand years ago, in different parts of the world, when microorganisms were introduced incidentally into local foods. Fermented foods are foods that have been subjected to the action of microorganisms or enzymes, in order to bring about desirable changes such as improved flavour, etc. Once harvested, fruits and vegetables are perishable due to the activity of bacteria, fungi, moulds, yeasts and enzymes. When acting on organic matter, these microorganisms and enzymes split their constituents, and turn them into simple compounds. Destroying these agents or controlling their activity help to keep fruits and vegetables in good condition. Creation of unfavourable conditions, such as humidity and temperature, extends the duration of storage for a certain period of time without changes in the nutritional value. In vegetable processing, salting and fermentation are related to each other. The fermentation of vegetables is a complex network of interactive microbiological, biochemical, enzymatic and physico-chemical reactions. Lactic acid fermentation is a valuable tool for the production of a wide range of vegetable products. A large number of vegetables are preserved by lactic acid fermentation around the world. Typically, these fermentations do not involve the use of starter cultures and rely on the natural flora. Food Industry also adapted the same technique. However, in recent years, artificial inoculation with selected strains and anaerobic conditions has been used in order to gain uniformity of the sensory quality of fermented vegetables and to reduce the duration of the process. Although there are an unspecified number of fermented vegetables available in the market, only fermented cabbage (sauerkraut), cucumber pickle and olive pickles are of real economic importance.

35.2 Sauerkraut

Sauerkraut is one of the most consumed fermented vegetables in central and southern Europe and in the United States. Sauerkraut is the product resulting from the natural lactic acid fermentation of shredded fresh cabbage to which salt is added at a concentration of 2.25–2.5%. A number of microorganisms play a key role in the transformation of fresh shredded cabbage into the fermented product called sauerkraut. Under proper conditions, the fermentation of shredded cabbage is a spontaneous process in which bacteria converts sugars present in cabbage into acids, alcohol and carbonic anhydride. Simultaneously, cabbage proteins undergo biochemical changes. The major end products of this fermentation are lactic acid, and to a lesser amount, other acids. Lactic acid bacteria are the most important organisms responsible for cabbage fermentation. The characteristic organoleptic and nutritional properties of sauerkraut are: low calorific value, high fiber content, absence of lipids and high level of essential micronutrients.

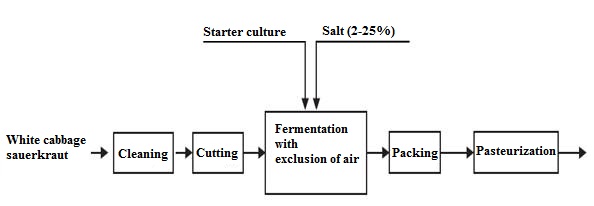

The main steps in the manufacture of sauerkraut are given in Fig.35.1. After removal of the outer leaves, green leaves and the core, the cabbage is washed and sliced into shreds as fine as 2.5 cm of thickness. This mass is placed in a fermenter in 2 kg layers alternating with salt layers, the first and last layers being salt. The salt is added at the rate of 2.5% of the weight of the cabbage to enhance the release of tissue fluids during fermentation. In order to create anaerobic conditions the layers are pressed mechanically, to remove the cabbage juice which contains fermentable sugars and other nutrients required for microbial activity. Anaerobic conditions promote the growth of lactic acid bacteria. This process takes about 31 days during which the average temperature is 14°C. The progress of fermentation is monitored every 2-4 days, by measuring the ascorbic acid and sugar content of the solid part, and the pH and acidity of the fermentation brine.

Fig. 35.1 General flow chart for the production of sauerkraut

Anaerobic conditions should be maintained to prevent growth of microorganisms that might spoil the sauerkraut. It has been found that different species of LAB sequentially involve in sauerkraut production. It is now well established that Leuconostoc mesenteroides grows first producing lactic acid, acetic acid and CO2. The pH of the product is lowered quickly, thus limiting the activity of undesirable microorganisms and enzymes that might soften the cabbage shreds. The carbon dioxide flushes out residual oxygen making the fermentation anaerobic which stimulates the growth of many lactic acid bacteria. Then Lactobacillus brevis grows continuing the acid production. Finally Lactobacillus plantarum grows which produces more acid and lowering the pH to below 4.0, allowing the cabbage to be preserved for long periods under anaerobic conditions. The end products formed contain significant amounts of lactic acid and a small amount of acetic acid and propionic acid, and a mixture of gases, CO2 being the most important. Minor end products such as diacetyl and acetaldehyde are also found. The major amount of the volatiles in sauerkraut is accounted for by acetal, isoamyl alcohol, n-hexanol, ethyl lactate, cis-hex-3-ene-1-ol, and allyl isothiocyanate.

35.3 Pickled Cucumber

Pickled gherkins are very popular and are mostly consumed without any other vegetables. The fermentation of cucumbers varies according to the salt concentration used, and two quite different products can be produced, namely high-salt stock (8–10% increasing to 15%) and low-salt dill pickles (3–5% salt containing dill and spices). Usually, the salt solution is poured onto the cucumbers in tanks and then fermentation is allowed to proceed, if necessary, glucose is added to stimulate activity. Fermentation takes place at 18–20°C and yields lactic acid, CO2, some volatile acids, ethanol and small amounts of various aroma substances.

Cucumbers for pickling must be harvested while still immature. They should not be crushed or bruised and should have a stalk of 1-2 cm. There should not be more than 6-8 hr between harvesting and brining to avoid spoilage. To obtain a uniform product, crushed, unsound, decomposed, defective and too mature cucumbers should be removed from the lot. Sorting is followed by size grading. A wooden, clay or glass tank is filled with 10-15% salt brine to cover the bottom to a depth of 15 cm. Then, previously washed cucumbers are put into the container and filled with brine to cover the cucumbers completely. Cucumbers are submerged into the brine with a white, perforated wooden cover. Cucumbers consist of about 90% of water which causes the salt concentration of the brine to be lowered during fermentation. Brine should be kept at 40° salinometer to prevent the activity of putrefying bacteria. However, the salt concentration should not be higher as this would cause inhibition of the activity of LAB. After 5-6 weeks, the brine is increased to 60° salinometer by adding salt. During fermentation, cucumbers change colour from bright green to olive green by action of acids on chlorophyll. The flesh of the pickles turns into an attractive translucent white when the curing process finishes by expulsion of air from the tissue. Initiating cultures are composed of a normal mixed flora of the gherkins. Fermentation is initiated by the following LAB, cited in order of importance: Leuconostoc mesenteroides, Enterococcus faecalis, Pediococcus cerevisiae, Lactobacillus brevis and Lactobacillus plantarum. Of these, Pediococcus and Lactobacillus plantarum are important, whereas Lactobacillus brevis is undesirable because of its ability to produce gas. Lactobacillus plantarum is the essential or indispensible species.

The two main defects of cucumber pickles are swelling or bloating and softening. Swelling, a serious problem in cucumber fermentation, generally increases with larger cucumbers, high fermentation temperatures, and/or an increase in the level of CO2 in the brine. Bloaters are those pickles that float on the brine and are hollow or have large air spaces in the interior. This condition is caused by gas-forming microorganisms, i.e. gaseous fermentation. Enterobacter spp., lactobacilli, and Pediococci have been implicated as causes of bloaters. Pickled cucumbers are often softened due to endogenous or microbial pectolytic enzymes. Softening is caused by microorganisms growing inside or on the cucumbers. Pectolytic organisms causing pickle softening belong to the genera Bacillus, Fusarium, Pencillium, Phoma, Cladosporium, Alternaria, Mucor, Aspergillus and others.

35.4 Olive Pickle

Olives (Olea europaea) are produced in great amounts in the Mediterranean area, California, South America and Australia among others. This fruit is processed for oil production (about 85%) and for table use (about 15%). Green olives are brined and fermented in a manner similar to cucumbers. Spanish, Greek and Sicilian are the most important types of fermented olives. Before brining, green olives are treated with a 1.25 to 2 % lye solution, depending on the type of olives usually at 21 to 25°C for 4 to 7 h. This treatment is necessary to remove some of the oleuropein, a bitter principle in the olives. After treatment, the lye is removed by soaking and washing the olives in fresh water. Excessive washing may induce a loss of some nutrients and a low acidity development due to a high loss of carbohydrates. To overcome these problems inoculation with Lactobacillus plantarum may be necessary to neutralize any residual lye. Adding sugar to the brined olives for acid production has also been suggested. Washed olives are then placed in a brine solution, the concentration of which varies from 5 to 15 % salt, depending upon the variety and size of olives. Additional salt is added during fermentation of olives in order to maintain a constant salt concentration, usually at 28° to 30° Salinometer level. Sugars, vitamins and amino acids pass, by osmosis, from the olives into the brine solution, gradually converting it into a suitable medium for the growth of microorganisms which produce lactic fermentation. The fermentation takes as long as 6 to 18 months, and the acidity of the final product varies from 0.18 to 1.27 % LA. A level of at least 0.6 to 0.7 % acid is needed for proper preservation and flavour of the product.

The lactic acid fermentation involves a number of microbial strains. The normal olive fermentation is divided into three stages. The initial stage is the most important from the standpoint of potential spoilage if the brines are not acidified. If the fermentation develops normally, potential spoilage bacteria are rapidly eliminated principally due to developing LAB which belong to the genera Streptococcus, Pediococcus and Leuconostoc and to a minor extent Lactobacillus. Acidification eliminates Gram-negative and Gram-positive spoilage bacteria and at the same time provides an optimum pH for activity of the LAB. If fermentation follows a different pattern, spoilage microorganisms become predominant. Generally, these are Gram-negative bacteria, which, if not controlled, produce gas and are very proteolytic. During the second or intermediate stage of normal fermentation LAB become predominant. Among these there are less acid-tolerant species belonging to the genus Leuconostoc and high acid tolerant Lactobacillus species. Initially, Leuconostoc species are predominant, declining rapidly in number by the end, when they are replaced by more acid-tolerant Lactobacillus species.If the fermentation is normal, Gram-negative bacteria disappears completely after 12-15 days. This stage takes 2-3 months. During the final stage, which lasts about < 25 olive fermentation is dominated by highly acid tolerant Lactobacillus species.

For the fermentation of black lactic-fermented olives, the ripe, violet to black fruit is washed and directly allowed to undergo spontaneous lactic fermentation in 8–10 % salt solution. A alkali treatment is not performed on black olives. Lactobacilli and yeasts are involved, but the yeasts normally dominate. The final product has a pH value of 4.5–4.8 and contains 0.1–0.6% lactic acid. Olives may undergo spoilage owing to the growth of undesirable microorganisms. Zapateria spoilage is characterized by a malodorous fermentation, due apparently to the production of propionic acid by Propionibacterium. Sloughing spoilage is a defect that includes severe softening, skin rupture and flesh sloughing. It is caused by Gram negative pectinolytic bacteria, especially Cellulomonas flavigena. Softening of olives is caused by the pink yeasts, Rhodotorula, and fermenting pectinolytic yeasts, Saccharomyces and Hansenula.