Module 10. Pickles and sauerkrauts

Lesson 36

TECHNOLOGY OF SELECTED PICKLES-II

36.1 Introduction to Oil-Based Pickles

Oil-based pickles containing one or more edible oils are highly popular in India. Mango, lime, cauliflower and turnip pickles are the most important oil pickles. Mango pickle is largely sold pickle in the country followed by cauliflower, onion, turnip and lime pickles. Cauliflower pickle is highly popular in Northern parts of India. For preparing the oil-based pickles, fruits or vegetables should be completely immersed in the edible oil. Oil pickles are generally highly spiced. The technology for the preparation of some of these pickles is given in this lesson.

36.2 Mango Pickle

The method of preparation of oil-based mango pickles varies in different parts of the country. The “avakai” pickle of Andhra Pradesh is a well known mango pickle in oil. It is very pungent and hot to taste. In north India, rapeseed /mustard oil is commonly used. But in south India, gingelly or sesame oil or groundnut oil are preferred. Hygienically prepared mango pickle should have a shelf life of about 1 to 2 years at room temperature. India, being the largest producer of mangoes, has great scope for export of mango pickles. Because of regional variations in taste, there are numerous recipe combinations of mango pickle. One of the recipes is given in Table 36.1.

Table 36.1 Recipe for mango pickle

|

S. No. |

Ingredients |

Quantity (g) |

|

1 |

Mango slices |

900 |

|

2 |

Common salt, powdered |

226 |

|

3 |

Grounded Fenugreek (methi) |

113 |

|

4 |

Grounded Nigella (kalaunji) |

28 |

|

5 |

Turmeric powder |

28 |

|

6 |

Red chilli powder |

28 |

|

7 |

Black pepper |

28 |

|

8 |

Fennel or aniseed (saunf) |

28 |

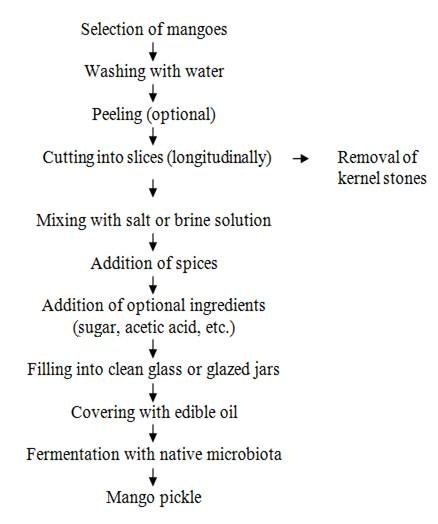

In the preparation of mango pickles, cultivar or variety which is rich in fibre is chosen e.g. Ramkhela, Sukul, Ashmina, etc. The flow diagram for the preparation of mango pickle is given in Fig. 36.1. For making mango pickle, fully developed but under-ripe tart varieties of mango are selected. They are washed with water; peeled or unpeeled and sliced longitudinally with a stainless steel knife. The mango kernel stones obtained during slicing are discarded. Sliced raw mangos are mixed with common salt to extract some of the moisture from the slices or immersed in brine solution of 2-3% strength to prevent blackening of the cut surface. To the drained slices, a partially ground mixture of spices including onions and garlic are added. Depending on the choice, availability and regional preferences the spices are selected and may include coriander, fenugreek seeds, nigella, fennel, cumin seeds, powdered turmeric and red chillies. The whole admixture is filled into a clean glass or glazed jars and covered with the chosen edible oil i.e. mustard or gingelly or groundnut oil. Table sugar is sometimes added in small amounts along with spices to produce a good taste blend. Also, if the mango variety is not sour enough, a small amount of acetic acid is sometimes added. Spices, oil and mango slices can be subjected to heating at low temperature for about 10-15 min. without softening the texture of the slices. Such heat treatment reduces the initial bacterial load and would help in attaining a longer storage life of mango pickle. Usually it takes 2-3 weeks for the completion of fermentation by natural microbiota. Pickles usually have a shelf life of about slightly more than 1 year when prepared and packed in hygienic conditions.

Fig. 36.1 Flow diagram for the preparation of mango pickle

36.3 Lime Pickle

Good quality lime are selected for making lime pickle and washed thoroughly before use. The cleaned lime fruits are sliced and cut into four pieces. About one-fourth of the cut lime fruit pieces are squeezed to extract juice. Later, the remaining lime pieces are mixed with selected spices, salt and extracted lime juice. Spices such as turmeric, red chilli powder, cardamom, cumin, aniseed, black pepper, etc. are used. The mixture is filled into clean glass or glazed jars kept usually in sunlight for about a week. During this period the useful biochemical changes takes places. At the end of one week, selected edible oil which is previously heated and cooled is mixed with the mixture and stored.

36.4 Aonla Pickle

Aonla, also called as amla or Indian Gooseberry, is a minor sub-tropical deciduous tree indigenous to Indian sub-continent. Aonla fruits are round, ribbed and pale green. It is divided into six segments through pale liner grooves. It is quite hard with a thin and translucent skin. The raw fruit, due to its high acidic nature and astringent taste, is unacceptable to consumers. Besides, aonla has been an important ingredient in chavanprash, an ayurvedic health tonic. Aonla fruits are rich in ascorbic acid and tannins. It contains 500-1500 mg of ascorbic acid per 100 g of pulp which is greater than that of guava, citrus and tomato fruits. Aonla has been used for pickle and preserve making since ages in India. Chakaiya is a popular cultivar or variety of aonla used for pickle preparation. The principle of manufacture of aonla pickle is the same as that of mango pickle. For making pickle, aonla fruits of suitable size are selected and thoroughly washed with water. The fruits are manually pricked and treated with salt and kept aside for few days. Spices such as turmeric, nigella seeds, red chilli powder, fenugreek, headless cloves, etc. and oil as per recipe are mixed to the salt treated aonla fruits and filled in suitable glass jars. The filled jars are kept for about a week in sunshine for the biochemical reactions to take place. Such pickle can be stored at room temperature and relished.

36.5 Spoilage of Pickles

Different kinds of spoilages occur in pickles. Some of them irrespective of the type of the pickle are briefly described as follows:

36.5.1 Shrivelling

Shrivelling occurs when vegetables like cucumber are placed directly in a very strong solution of salt, sugar or vinegar. Use of weak solutions to start with and later gradually increasing their strength avoids such defect.

36.5.2 Bitter taste

Bitter taste in the pickle may result from use of strong vinegar or prolonged cooking of spices or addition of excess amounts of spices.

36.5.3 Blackening

Blackening defect in pickles may result from use of iron knives for cutting the fruits and vegetables and use of iron containers for processing. Further, it may also result from growth of specific molds that cause blackening.

36.5.4 Dull or faded products

Pickles become dull and faded either due to use of inferior raw material or due to insufficient curing.

36.5.5 Softness and slipperiness

This is a most common defect and results due to the action of bacteria. Insufficient covering with brine or use of weak brine or insufficient covering with oil are invariable causes for this defect. By using a brine of proper strength and by keeping the pickle well below the surface of the brine or oil, this kind of spoilage can be eliminated.

36.5.6 Scum formation

When vegetables are placed in the brine for curing, a white scum is invariably formed on the surface due to the growth of wild yeast. This scum retards the formation of lactic acid and helps the growth of putrefactive bacteria that causes the vegetables to become soft and slippery. Hence, it is essential to remove the scum as soon as it is formed. Addition of about 1% acetic acid helps to prevent the growth of wild yeast in the brine, without hindering the formation of lactic acid.

36.5.7 Cloudiness

This defect is usually found in case of onion and some other vegetables and occurs when vinegar become cloudy and turbid, thereby spoiling the appearance of the pack. This could be due to microbial activity or due to the use of inferior quality or possible chemical action between vinegar and impurities such as calcium, magnesium and iron compounds.