Module 11. Confectionery products

Lesson 37

CONFECTIONARY PRODUCTS: PRINCIPLES AND CLASSIFICATION

37.1 Introduction

Confectionery is an important food item of great popularity among wide range of population. It has been enjoyed as a major food delicacy from ancient times. The term confectionery is ambiguous and describes a spectrum of sweet goods and takes on different meaning depending on the country in which it is used, for example in the United Kingdom the term applies to any sweet product including cakes. In the United States confectionery is candy and includes sugar confectionery and chocolate confectionery. Globally, confectionery foods represent 50% by volume of foods produced and 60% by value. The Indian confectionery market is estimated to be 1,38,000 metric tonnes (in 2005) and is segmented into sugar-boiled confectionery, chocolates, mints and chewing gums. Sugar-boiled confectionery consisting of hard-boiled candy, toffees and other sugar-based candies, is the largest of the segments and it is valued at around Rs. 20,000 million. Some of the largest companies active in the confectionery sector are Cadbury, Nestle and Perfetti. In India, confectionery foods are worth Rs.2,250 Crore with an annual growth rate of 2%.

37.2 Classification of Confectionery

Confectionery can be classified into four major groups. They are as follows:

37.2.1 Sugar confectionery

It includes products using mainly sugar such as boiled sweets,fondants, fudge, jellies, toffees, etc.

37.2.2 Chocolate confectionery

It includes mainly cocoa, chocolate and chocolate products. Sugar confectionery coated with chocolate is also included in it.

37.2.3 Flour confectionery

It includes baked products such as cakes, biscuits, cream rolls, etc. Traditional Indian cereal and legume flour based sweets such as mysorepak, soanpapdi, badushah, jalebi, etc. are also included in this category.

37.2.4 Milk-based confectionery

It includes mainly Indian traditional milk-based sweets such as burfi, peda, rasogolla etc.

In sugar confectionery, sugar is the main or principal ingredient while in other confectionery sugar is used as one of the ingredient.

37.3 Sugar Confectionery Groups

Depending on the structural geometry, sugar confectionery is grouped into two major groups: amorphous and crystalline.

37.3.1 Amorphous sugar confectionery

These products are characterized by hard, chewy, homogenous and non-crystalline nature. It includes hard boiled candy, caramels, toffee, taffy, brittles, gums, jellies, etc.

37.3.2 Crystalline sugar confectionery

These are characterized by

crystal structure. It includes chocolate, fondant, nougats, fudge,

marshmallows, etc.

37.4 Raw Materials and Ingredients Used in Sugar Confectionery

The raw materials and different ingredients used in sugar confectionery are sucrose and its derivatives, glucose syrups, other sugars, other sweeteners, fats, milk products, foaming agents, gelling agents, thickeners and stabilizers, colours, flavours, acids, nuts and some processing aids.

37.4.1 Sucrose

White sugar extracted from sugar cane or sugar beet is very nearly pure sucrose with traces of mineral matter.

37.4.2 Sucrose derivatives

Alternative to sucrose, sometimes liquid sugar with less than 75% solids, brown sugar, icing or milled sugar, golden syrup with about 80-83% soluble solids, invert sugar, refinery syrups which are darker than golden syrups with more flavour, molasses and dark treacle, etc. are used.

37.4.3 Glucose syrups

Glucose syrup is occasionally called as “confectioners' glucose”. It contain a number of different sugars all built up from dextrose units, with dextrose and maltose predominating. The pH of the glucose syrup ranges between 4.8 and 5.2. The grading of glucose syrup is based on the solids content as indicated by Baume reading and on the reducing sugar content of the solid matter calculated as dextrose (termed as DE value or dextrose equivalent value). Many grades of glucose syrup are available to the sugar confectioner including 35 DE (low DE), 42 DE (regular DE), 55 DE, 63 DE (high DE) and high maltose glucose syrup. The average TSS content for glucose syrups ranges between 78 and 83%. High maltose glucose syrups contain maltose as high as 75% with very low dextrose contents. High fructose corn syrups (HFCS) are produced by isomerization of dextrose to fructose by enzymes. Usually HFCS contain fructose in the range of 42 to 90%. Confections made with HFCS are sweeter than those made with conventional glucose syrups.

37.4.4 Honey

Honey is a clear liquid ranging in colour from pale straw to brown. The water content of most honey ranges between 15-20% depending on the area of origin. It contains about 40% fructose, 34-38% dextrose and 4-5% sucrose. Upon prolonged storage, the dextrose may crystallize out.

37.4.5 Intense sweeteners

Sugar replacers are sometimes used in sugar confectionery for making low-calorie or dietetic confectionery products. The intense sweeteners such as aspartame, acesulfame-K, saccharin, cyclamates, etc. exhibit sweetness many times that of cane sugar. The relative sweetness of aspartame and acesulfame-K is 180 and 200 times, respectively compared to sucrose. Their use is widespread in chewing gums than in other confectionery.

37.4.6 Bulk sweeteners

Bulk sweeteners provide sweetness to a lesser extent compared to equal weight of sucrose and hence provide fewer calories. However, they provide significant bulk to the formulation. They include polyols such as sorbitol, mannitol, isomalt, maltitol, etc. Substances which are non-caloric or low-calorie fillers and provide no sweetness are often used in low-calorie confectionery and are called as bulking agents. These provide functionality similar to sugar e.g. polydextrose.

37.4.7 Fats

Fats for confectionery use must be completely or almost completely melted at about 37°C. If they have higher melting point they give an unpleasant greasy sensation in the mouth. On the other hand, low melting fats lack body and tend to make sweets oily, which can also result in bloom defect on chocolate covered products. Cocoa butter has almost ideal properties for use in confectionery. Lauric fats such as palm kernel and coconut oils, partially hydrogenated oils such as soy, ground nut, rapeseed, etc. are also used. Butter is used mainly for its flavour.

37.4.8 Emulsifiers

The usual emulsifiers used in confectionery are lecithin or glycerol monostearate. Both are used to assist the emulsification of fat into product but while the lecithin is generally used for hard boiled sweets, glycerol monostearate is preferred for toffees and caramels as it provides lubrication for cutting knives during processing.

37.4.9 Milk products

Milk products such as spray dried milk powder, sweetened condensed milk, sweetened condensed skimmed milk, whey powder, sweetened condensed whey, etc. are used for their nutritive value, flavour and sometimes colour generated due to Maillard browning and caramelization.

37.4.10 Gelling agents, thickeners and stabilizers

These substances are mainly used for binding water and gives strength to the confectionery products. Gelatin, starch and modified starches, pectin, gum arabic, guar gum, locust bean gum, xanthan gum, alginates, etc. are commonly used.

37.4.11 Colours

Many foods in the natural state are coloured and in many cases the colour influences the consumer’s perception of flavour. Most confectionery products are not naturally coloured so colours are added to assist in flavour perception and to provide a means of differentiation between sweets in an assortment of flavours. Natural colours such as caramel and permitted artificial colours are commonly used in confectionery.

37.4.12 Flavours

Natural flavours, essential oils, and artificial flavours are used in confectionery applications. All flavours are to a greater or lesser extent volatile and in confectionery applications they are often added at high temperatures.

37.5 Confectionery Production Principles

All confectionery products have a number of common requirements. They must have an extended shelf life under ambient storage conditions and although this may be assisted by protective packaging their inherent properties must provide stability against microbial deterioration and stability of shape. In sugar confectionery, shelf life is achieved by reducing water activity through control of the composition and RH during storage. Stability of the shape is aided by the inclusion of ingredients such as gelling agents or fats which create structure and prevent flow during storage.

By formation of a gloss as in hard boiled sweets, toffee and nougat or by allowing crystal growth as in fondant creams. Also, soft or liquid centres may be held firm by being enclosed within a rigid shell.

37.5.1 Key ingredients used in sugar confectionery

The prime ingredients of the sugar confectionery are sugar, glucose syrup or invert sugar and water. The purpose of reducing sugars is to control or prevent crystallization in the product; whether crystallization occurs or not, it is essential to ensure that the level of dissolved solids in the water never falls below 76% in order to prevent microbial deterioration.

37.5.2 Equilibrium relative humidity

In a perfectly dry atmosphere all sweets will lose moisture. As the relative humidity of the atmosphere increases, a point will be reached when the sweet ceases to lose moisture and at higher relative humidities the sweet will absorb moisture from the air. The relative humidity of the atmosphere when a sweet neither gains nor loses the moisture is equilibrium relative humidity (ERH) of the sweet and is a function of its water vapour pressure. This is mainly dependent on the moisture content of the sweet, or of the liquid portion in the case of sweets containing liquid and solid components. It is affected to a lesser degree by the molecular weight of the dissolved sugars. Crystalline solids such as sugar crystals have no effect on the ERH of a syrup in which they are dispersed. Other solids such as cocoa, starch and desiccated coconut absorb moisture and the amount depends on the ERH of the solution in which they are contained. The effect is usually small. In sugar confectionery, any ingredient which reduces ERH is called as a humectant. The commonly used humectants are glycerol, sorbitol, etc. The typical ERH values for confectionery products are given in Table 37.1

Table 37.1 Equilibrium relative humidity (ERH) values of some confectionery products

|

Type of Confectionery |

ERH Value (%) |

|

High boilings |

20 |

|

Toffees and nougats |

45 |

|

Fudge |

60-65 |

|

Jellies |

70 |

|

Fondants and coconut ice |

75-80 |

37.5.3 Sugar solubility

Sugar dissolves in water to give a saturated solution of 67.1% solids at 20°C. However, up to 74% solids, undisturbed sugar syrup will not crystallize unless seed crystal is present or mechanical or thermal shock is encountered. This metastable state is utilized in the wet crystallization process. The presence of invert sugar or glucose syrup increases solubility of sugar and TSS in solution at saturation. It has been found experimentally that total solids up to 84% can be obtained assuming that glucose or invert solids dissolve in water in the ratio 6.69 to 1 to give an 87% solution and the remaining water dissolves sugar in the ratio of 1 to 2.03 to give a 67.1% solids solution.

37.5.4 Sugar boiling

The quantity of water evaporated when a sugar solution is boiled under constant conditions is related to the boiling temperature. Water boils at 100°C under standard atmospheric conditions. The addition of sucrose, or any other sugar, increases the boiling point in a non-linear manner and is related to the concentration of sugar in solution. The boiling point of some common sugar confectionery products is given in Table-37.2. Problems arise at higher temperatures because heat transfer through fairly viscous syrups is not good. The presence of sugars other than sucrose will affect the boiling point of the solution in different ways. Variations in barometric pressure will affect the boiling the point of a sugar syrup. The variation in the height of the mean sea level for the location of a sugar confectionery factory can give rise to differences in the boiling point of sugar syrup.

Table 37.2 Boiling point ranges of some common sugar confectionery products

|

Type of confectionery |

Temperature range for boiling (°C) |

|

Hard-boiled sweets |

149-166 |

|

Hard toffee |

146-154 |

|

Fudge |

116 |

|

Fondant |

116-121 |

|

Caramels and regular toffee |

118-132 |

37.5.5 Sugar crystallization

The structures of products such as fondat creams, coconut ice and fudge are produced with formulations which contain enough sugar to crystallize on cooling. When a supersaturated solution is seeded with existing crystals, usually by the addition of fondant, crystallization occurs throughout the mass. The crystal size may be controlled by varying the degree of supersaturation, the amount of seed crystal and the temperature. By varying these, textures ranging from firm pastes to hard products (where the crystals have grown into each other and formed a rigid structure) may be achieved.

37.5.6 Aeration

Aeration may be applied for a number of reasons such as increasing volume for a given weight of product and creating opacity, but the main reason is texture modification. It can be achieved by beating where foaming agents and stabilizing agents are necessary, or it may be done by pulling or liberation of gas under vacuum where the setting of the matrix by cooling stabilizes the structure. Egg albumin, whey proteins and enzyme modified soy proteins are commonly employed as aerating agents.

37.6 Confectionery Production Processes

The processes commonly employed for the production of confectionery products are briefly described below:

37.6.1 Cooking

Cooking of sugar is usually carried out in either gas fired cooking pans or in steam-jacketed kettles. Sometimes vacuum is applied for cooking at low temperatures. Cooking is carried out to achieve high temperatures for dissolving sugar. It also frequently involves caramelization of sugars.

37.6.2 Drop rolling

The drop roller was one of the earliest sweet forming machines. It consists of two synchronized brass rolls engraved with matching impressions. The processed confectionery mix in the form of a plastic mass is fed into the rolls and forced into the impressions.

37.6.3 Moulding

Depending on the type, confectionery products are moulded in different ways. Boiled sweets are deposited into teflon-coated aluminium moulds fitted with ejector pins. After cooling, the pins are depressed from the underside of the moulds to eject the solid boilings. Toffees are deposited in silicone rubber moulds. After setting, the mould is deformed by plungers which push the toffee out.

37.6.4 Extrusion

Extruders of various types are used for forming bars and sheets from pastes and plastic confectionery bases. Lozenges are formed by passing the paste through a screw extruder and die to form a sheet which is then reduced in thickness by subsequent sizing rollers. In case of bars, the sheets are slit by rotary knives and sized to desired length.

37.6.5 Plastic forming

The plastic forming operation is widely used in the confectionery industry for converting plastic masses such as boiled sugar or toffee into individual sweets. In this process, the product will be tempered to correct consistency and flavour ingredients incorporated during the kneading process in the case of boiled sugar or on a slab, cooling drum or cooling conveyor in the case of toffees. The mass is then fed into a batch roller for obtaining the product in the form of a rope. The rope is the fed to a presizer followed by sweet former (to give desired shape to final product) and later packaged.

37.6.6 Wet crystallizing

Wet crystallizing is the process of building up a thin coherent coating of sugar crystal on the surface of a sweet. This seals the surface, and when used on products such as fondant creams or marzipan, retards drying out, extending the shelf life from a few days to 6 months or more.

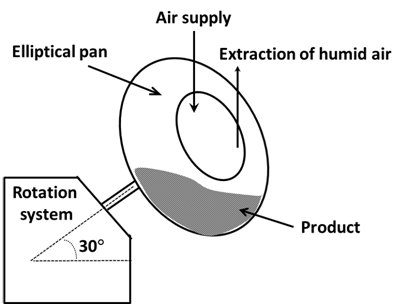

Fig. 37.1 Schematic diagram of a simple dragee pan

37.6.7 Panning

Panning is an operation which has been used by the confectionaries for centuries. In principle it is the application of coating to centres tumbling in a revolving pan mounted at about 30° to the horizontal (Fig 37.1). The operation consists of adding enough coating medium to cover the centres completely with no surplus and drying this off either with hot air (hard panning), extra sugar (soft panning) or cold air (for chocolate). Coatings may be sugar syrup (hard panning), glucose syrup dried off by the application of fine sugar (soft panning) or chocolate, solutions containing food grade colours, edible gums, etc.