Module 11. Confectionery products

Lesson 38

CANDIES

38.1 Introduction

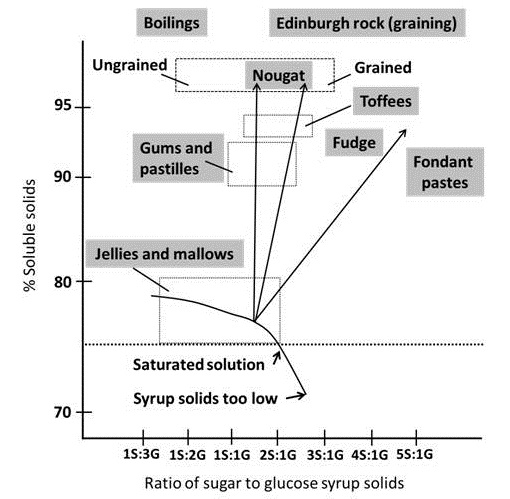

Candies represent a subgroup of amorphous sugar confectionery which are characterized by hard, chewy, homogenous and non-crystalline nature. These are also called as glass. The glassy state of matter is not a thermodynamic phase but a supercooled liquid and exhibit a sharp transition temperature between glassy and rubber states. Most sugars will form a glass but pure sucrose does not form a glass. Therefore, commercial sugar glasses are always made from sucrose and some other sugars such as invert sugar, glucose syrup, etc. Any additive required to stabilize a sucrose glass is traditionally referred to as a “doctor” by confectioners. Sometimes, acids are added to sucrose for in situ generation of invert sugar. In practice, boiled sweets (or high boilings) become unstable by absorbing water. Initially the product becomes sticky, then soft, followed ultimately by crystallization. The rate at which high boilings can absorb water is controlled by diffusion process and the high molecular weight fraction in glucose syrup inhibits the migration of water into the sweet. The important parameter at the formulation stage is the ratio of sugar to glucose syrup. The ratios of sugar to glucose syrup in common types of sugar confectionery is given in Fig. 38.1

Fig. 38.1 Sugar (S) and glucose (G) composition of different sugar confectionery products

38.2 Hard Boiled Candies

Boiled sweets or high boilings are originally made by boiling a sugar solution with cream of tartar over coke fires to about 150-155°C. The cream of tartar inverts some of the sugar and the resulting mass, comprising of a mixture of sucrose, dextrose and fructose at about 97% solids. They are usually coloured, flavoured and set to a transparent glassy product. However, the coke fires are now replaced by steam and processing is done in vacuum pans (635-760 mm Hg) for improved heat efficiency. The sugar from high vacuum cookers is a viscous plastic mass. The plastic mass is usually shaped, cooled and wrapped in moisture-proof packs as rapidly as possible, preferably while still hot. The resultant candies have very low residual moisture usually in the range of 1-2%. Candies based on invert sugar are very hygroscopic and readily develops stickiness on exposure to the atmosphere. Hence, glucose syrup is often included in the formulation to avoid stickiness. Sugar/glucose syrup or sugar/glucose syrup/invert sugar combinations are widely used in confectionery. The ratio of sugar to glucose for making hard boiled candies range from 30% sugar and 70% glucose (1S:3G) to 50:50 mixtures (1S:1G) (Fig. 38.1). The process of making boiled candies can be summarized as follows:

a. Dissolving the sugar

b. Boiling the sugar and glucose syrup under vacuum to the final solids concentration

c. Cooling the boiled mass

d. Adding flavour, colour and any acid

e. Shaping the product

f. Wrapping

38.3 Brittle

Brittle is essentially a type of hard candy to which nuts like peanuts are very commonly added. The nuts are added to the hot syrup and the mixture is poured out in a very thin layer and then stretched to make it as thin as possible. Baking soda (sodium bicarbonate) is sometimes added to produce a light texture. The resulting candy is hard and snaps easily, hence the term “brittle”.

38.4 Compressed Tablets

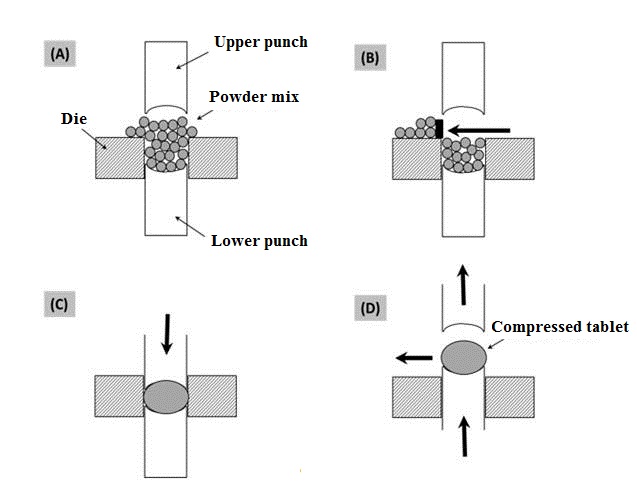

Candies produced by application of high pressure processing are called compressed tablets or pressed candies. It involves use of punches and dies to provide desired shape. For tablet sweets, icing sugar and dextrose are normally used as a base, with gelatin, gum acacia or gum guar as binding materials. Stearic acid and its salts are normally used as lubricants. The amount of binding agent and lubricant used in compounding the formulation influences the physical properties of the tablet. There are two methods of producing compressed tablets: slugging and wet granulation. In slugging, the powder mix is treated with a lubricant before precompression into large granules. The slugging operation of tablet press is shown in Fig.38.2. For wet granulation, sufficient binder solution is added to the dry ingredients to make a malleable paste. The paste is then forced through a wide meshed sieve and dried in an oven at 32-65°C. The dried mixture is treated with a lubricant and flavour and sent for pressing. Pressing is carried out in continuous machines which operate at high speed. The tablets can be formed either in single or multiple die actions in which the lower and upper dies are brought together under pressure.

Fig. 38.2 Operation of a slugging tablet press

(A). Die is filled with powder; (B). Excess powder is removed; (C). Powder is compressed between punches; and (D). Upper punch is raised and tablet is ejected by lower punch.

38.5 Crystalline Fondants and Creams

Fondants are more solid and are used in preparing items such as peppermint patties, while creams are softer and used in making chocolate covered products. The main difference is in the degree of hardness and crystal size. All fondants are prepared from a blend of sucrose and other sugars such as invert syrup or corn syrup. Blend is usually heated to a temperature of 115-120°C and cooled to about 37.8°C without agitation. When agitated, it initiates crystallization to produce a product with a crystal size of about 15 mm.