Module 11. Confectionery products

Lesson 40

TOFFEES AND CARAMELS

40.1 Definition of Caramel and Toffee

Caramel and toffee are one of the most basic and yet versatile candy products and constitutes a large part of the confectionery industry. Both are versatile and widely used confectionery products after chocolate. They produce images of delicious, chewy taste in the minds of consumers.

Word “Toffee” was used to denote those products that do not contain milk solids and prepared by using brown sugar, glucose syrup and fat mainly butter fat. They appear in many aspects quite similar to butterscotch but differ in the intensity of heating. Unlike butterscotch they contain slightly higher moisture content. Processing of milk led to the inclusion of milk solids in toffee formulation and resultant product contains slightly higher moisture in the range of 8-9 percent. The demarcation line between caramel and toffee is very thin. Differentiation between the two can be done on the basis of moisture content which is slightly higher in caramel as compared to toffee. Term “Caramel” is also used to describe products made by the breakdown of carbohydrate by heat or heat and alkali treatment. These are mainly used as colouring matter.

Caramel may be found in a range of textures, colors, flavors and products. This common confection may be consumed alone as or in combination with chocolate, nougat, marshmallows, nuts and other inclusions. Some applications include caramels wrapped for consumption, for depositing into chocolate shells, as ice cream toppings and ingredient in other confections or desserts. Likewise “Toffee” is also available in various textures ranging from soft to hard brittle, which is mainly governed by the composition and final cooking temperature.

Fudge is another type of confectionary product which resemble to caramel or toffee but differs in the processing as in it sugar crystals are developed during the cooking. Normally it contains more sugar and milk as compared to toffee or caramel. The mixture of sugar, milk and butter or vegetable fat is heated to soft-ball stage (116°C) and then beating the mixture when it cools so that it can acquire a soft, creamy consistency. The characteristics of fudge are more dependent on processing conditions rather than formulation. The three important criteria for good quality fudge are:

· Must be microbiologically safe

· Must be firm

· Should have uniform texture

40.2 Properties of Caramel and Toffee

They may be described as ‘soft glasses’ that are viscous in nature and contain a dispersion of milk protein and an emulsion of fat in highly concentrated sugar solution. Caramel is manufactured by heating mixture of sugar, corn syrup, fat and milk solids (protein) at 110-130oC, followed by cooling and moulding of cooked mass. Soft caramel which is used as a layer in confectionery bars is prepared by heating to the lower temperature range and has a moisture content of about 10%. The resulting product is a viscoelastic liquid consisting of fat droplets in a matrix of sugars and protein. Toffee or caramels can be deliberately made to crystallize or grain and are then called as grained caramels or soft toffees. These products are quite similar to fudge but are made by adopting altogether different process.

The texture of caramel must be controlled in order to achieve the desired flow patterns and machinability in the production lines, to maintain product specifications and to ensure a long shelf life.

40.3 Technology for the Manufacture of Caramel and Toffee

40.3.1 Equipment for toffee and caramel manufacture

Traditionally toffees were made on fuel or gas fired pans or steam-boiling pans. These pans were fitted with a bow-shaped stirrer and hinged scrappers which are thrown outward by centrifugal forces to remove the cooking toffee from every part of the heating surface. However, a continuous toffee plant consists of following parts.

40.3.1.1 Auto-feeder

It is maintained at 35°C and receives all the raw material except flavouring and butter and followed by a reservoir to surplus feed before transferring into pre-heater through metering pump.

40.3.1.2 Pre-heater

The feed material is fed into this section which is attached with scrapper to dissolve and mix all the content with heating to a temperature of 95°C. The cooking is done by steam and by changing the steam pressure, temperature can be controlled. The residence time is regulated by a weir and the section contained a variable-speed rotor assembly. The rotor is designed to give a thorough mixing with a degree of back-mixing.

40.3.1.3 Blender

The heated mix is transferred to a blender which is quite similar to cooker but smaller than it. This unit is for the addition of butter and flavour. This section also has a weir to control the residence time.

40.3.1.4 Cooker

In the cooker, the emulsified mass is cooked thoroughly to desired cooking temperature which is adjusted by steam pressure. The residence time is also controlled by the speed of shaft to remove sufficient moisture and allow caramalization to occur.

40.3.2 Manufacturing process

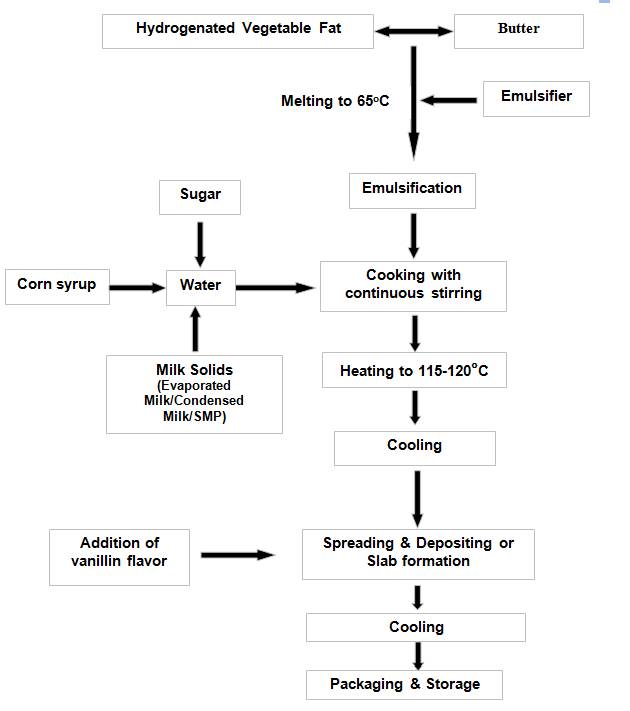

Caramel is manufactured either following traditional batch process or continuous method. The process can be considered taking place in five basic steps viz. pre-mixing, emulsification, cooking, cooling and forming either through slab formation or depositing. A generalized process flow diagram for the manufacture of toffee and caramel is given in Fig.40.1.

40.3.2.1 Pre-mixing

Pre-mixing of ingredients is done separately for fat phase and aqueous phase. For fat phase preparations butter/milk fat is mixed with melted vegetable fat and emulsifier at desired speed to mix the components. Sugar is dissolved in required quantity of water, mixed with milk solids and melted corn syrup.

40.3.2.2 Emulsification

Both aqueous and fat phases are emulsified by using high speed mixer. Emulsification must be adequate to get the desired texture and other quality attributes in the finished product. Emulsifier and milk protein assists in emulsification.

40.3.2.3 Cooking

Cooking of caramel or toffee at desired temperature is essential to develop proper texture and organoleptic quality specially the flavour and colour. Cooking temperature also affects the final moisture and it influences the texture and chewiness. The end product moisture content in caramel cooking is generally controlled by the final cooking temperature. Caramel or toffee cooked to 125°C-130°C contains around 6-8% moisture. Provided sufficient fat is present, the product so produced will have a pleasant chewing characteristic. Higher cooking temperatures of up to 145°C must be employed with these products meant for hot climate. These are less likely to grain (crystallize) during storage.

40.3.2.4 Cooling and depositing

The cooked mixture is transferred to depositor or forming unit where both cooling as well as shaping takes place. The cooling is essential to prevent over-cooking of the caramel or toffee. There may be three distinct processes for shaping. It includes slab process, the cut and wrap process and depositing process.

40.4 Role of Ingredients in Manufacture of Caramel and Toffee

The ingredient used in caramel formulation can be categorized into two group viz. functional ingredient and optional ingredient.

· Functional ingredients include sugar, corn syrup, fat and milk solids

· Optional Ingredients include water, salt, flavouring and emulsifiers

The rheological, textural, thermal and structural properties and sensory characteristics of caramel depend on the functionality of four basic ingredients in the formulation viz. carbohydrate, fat, milk solids (milk protein) and water.

40.4.1 Carbohydrate in caramel

Carbohydrate contributes to final stand up texture to caramel. Carbohydrate generally used in caramel formulation is from sugar and corn syrup.

40.4.1.1 Sucrose

The major carbohydrate in caramel formulation is sucrose which provides bulking and sweetness. Sugars in confections can exhibit textural differences due to its amorphous state and/or crystallization (number and the size of crystals). Sugar counteract to corn syrup, as it reduces the stickiness and cold flow caused by higher amount of corn syrup in formulation. Typically, with an increase in sucrose there is a decrease in chewy texture of caramels. If there is a higher proportion of sugar in the formulation, there is an increase in graining potential. Graining occurs when the sugar in a confection crystallizes and causes an appearance that may be desirable or undesirable, depending on final application. Increasing the level of sucrose will increase the toughness of the caramel and the likelihood of graining during storage.

Fig. 40.1 Process flow diagram for the toffee and caramel manufacture

40.4.1.2 Sugar syrup

Glucose syrup/corn syrup and invert sugar syrup (containing an equivalent level of dextrose and levulose) are known traditionally as doctor sugar from their properties of increasing the total sugar concentration. Corn syrup plays a vital role in deciding caramel texture and its sensory appearance particularly colour development and chewiness of caramel. The dextrose equivalent of corn syrup is governing parameter with 42 DE being widely adopted. Corn syrup with higher DE results in darker colour, whereas low DE corn syrup provides excessive chewiness and stickiness to caramel. Corn syrup prevents sugar crystallization in caramel, thus checks product dryness. The ratio of sugar to corn syrup has a significant effect on the graining potential, and thus the shelf life, of a caramel. The higher proportion of sucrose in the caramel leads to an increased tendency to grain but it bites more cleanly. If the amount of corn syrup in the formulation is higher there is an increase in browning, stickiness and elasticity. A ratio of 40:60 sugars: corn syrup is sufficient to inhibit graining. Caramels are normally produced to a moisture content of between 6 to 7%. At this water level solution of sucrose, glucose syrup and invert sugar are supersaturated. Crystallization is inhibited by the highly viscous nature of the caramel boil. This is due to presence of low water content, from the presence of higher saccharides in glucose syrup and the chemical reaction which takes place between the milk protein and the reducing sugar that are present.

40.4.2 Fat

Fat in caramel aids richness to flavour and improves textural properties. The presence of fat makes significant contribution to the texture, chewing characteristics, color and flavor of caramel. The fat should have a balance between butter to contribute flavour and texture and hardened plant oil (hydrogenated fat) for stability. Fat, generally, used in caramel is from dairy source and vegetable fats such as coconut oil, hydrogenated vegetable oils, and partially hydrogenated palm oil (HPO) or palm kernel oil (HPKO). The fat also acts as lubricants, and phospholipids present in milk fat act as emulsifiers. The level of fat in caramel ranges from 5 to 20%, typically at 10 to 12%. Low fat levels tend to produce caramels that are sticky and difficult to chew while a high fat product without the addition of an emulsifier will lead to 'oiling out' on the surface of the confection. The melting point of fat source used is very important in terms of functionality in product. The melting point of fat should range between 29.4 and 46.1oC when vegetable fat is used for good standup quality and mouth-feel. A melting point higher than the recommended range could lead to a waxy mouth-feel upon consumption. Fat provides shortening effect to caramel and reduces the stickiness in product. Fat also affects the adhesion properties of caramel. Lipid may also affect the shelf life stability of a caramel with the potential for rancidity or fat expression. Fat expression is a defect that occurs when there is poor emulsification and results in a greasy caramel surface.

40.4.3 Milk solids

Milk solids impart three important characteristics to caramels, (a) they produce the background milk flavor, (b) the protein and fat aid in producing the texture and chew and (c) the proteins and lactose interact during heating to produce the characteristic caramel flavour. The most common form of milk solids used for high quality caramel is cream, evaporated milk, and sweetened condensed milk. Whey powders and sweetened whey have gained popularity as economical substitute for nonfat milk solids. But due to higher amount of lactose they can substitute only up to 50% of the nonfat milk solids can be replaced by whey. The resulting caramel is slightly softer. Milk fat imparts a richness to flavour. It also serve as a lubricant, which in turn facilitate its machinability, affects candy texture, controls sugar crystallization and adds flavor.

Milk proteins can have pronounced effects on the texture and rheological properties of a food system, by forming complexes among themselves and with the other constituents in the system. The functional properties of milk proteins result from their interactions at three levels: 1) protein-water interactions; 2) protein-protein interactions; 3) protein surface interactions. Caramel is an example of a complex food product in which milk proteins are expected to play a major role in controlling the textural properties. The functional properties of milk proteins in food systems can be categorized into solubility, viscosity, water binding, gelation, cohesion/adhesion, elasticity, emulsification, foaming, fat and flavour binding (Except for foaming, all of the above functionalities are exhibited in caramel.

Caseins and whey proteins, two major classes of proteins in milk, aid in efficient mixing of ingredients by promoting emulsification and improving emulsion stability. Caseins have the ability to bind more than twice their weight of water, thus producing a drying effect. Water absorption capability of whey proteins can be increased by heat denaturing. The foaming properties of whey protein exceed those of caseins. Caseins can produce a firm chewy body, neither sticky nor tough, while whey proteins form a soft coagulum with less resilience. The final colour and flavour of confection also reflect contribution from milk proteins. Caseinates, largely responsible for milk’s white colour, contributes to whitening effect. Caramel is a multi-component system, in which interactions between casein and whey proteins and the interactions of these proteins with the other ingredients are inevitable. The firmness of caramel was significantly affected by both whey and casein proteins. The increased firmness is not only attributed to higher amount of protein but this is due to physical and/or chemical interaction between these two proteins. Furthermore, there appeared to be a synergistic effect between whey and casein proteins on the caramel firmness. Maximum firmness occurred when the two proteins i.e. casein and whey protein, were adjusted to 1:1 ratio.

Lactose can have an important effect on the flavour, colour, and texture of confection. Flavours depend on cooking temperature and time, acidity of mixture, and presence of free amino group. Lactose, the least sweet of the principal sugars used in confections, can be added to establish flavour balance.

40.4.4 Emulsifier

The naturally present lecithin in milk is helpful in exerting emulsifying properties in the caramel but the level is present is insufficient to emulsify the mix effectively. It is necessary to boost the emulsifier content by adding glycerol monostearate (GMS) or oleate or oilseed lecithin, butylated glyceryl monostearete, sucrose esters or acetylated monoglyceride. Lecithin and GMS are the emulsifiers typically used in caramels at 0.2 to 0.3% of the lipid content. The emulsifiers are believed to increase the average size of the fat droplet at the caramel surface. It is essential that the fat dispersed in the syrup phase should be in a small globule size if a greasy taste is to be avoided.

40.4.5 Salt

Salt is added to caramel to enhance the flavour. It also acts as humectant and is necessary to prevent the product from being too bland. An optimum mixture of carbohydrates, protein and fats in caramel product largely dictates the rheological, thermal and structural properties, and, therefore, affects the operation and functional properties. Interaction of three basic ingredients namely carbohydrates, proteins and fats along with water and other minor additives during shearing, mixing and heating make an interesting combination in product formulation.

40.5 Packaging and Storage of confectionary

Confectionary products are rich in sugar and hence they are hygroscopic in nature. Moreover, some of them contain appreciable amount of fat and milk solids which make them susceptible to hydrolysis and oxidation. Hence, they require protection against the ingress of moisture, oxidation and exposure to high temperature. Some of the products are also prone to graining and stickiness and their equilibrium relative humidity (ERH) value is below 30 percent. Selection of packaging materials for these confectionary products required complete knowledge of water vapour transmission rate (WVTR), oxygen transmission rate (OTR), permeability to volatiles and flavours, grease resistance, tensile strength and elongation, tear strength and heat & seal strength. A wide variety of packaging materials, besides cellulosic and aluminum foil are used for confectionary items. The choice of packaging material depends on required shelf-life, performance of wrapping machine, and the cost. The most common choice is plastic and their laminate based flexible packaging materials have replaced the paper and aluminum based packaging materials owing to their better properties and lower cost. Low density polyethylene (LDPE), is an economical packaging material with a very low WVTR, but permeable to volatiles/flavours and have poor grease resistance. High-density polyethylene (HDPE), is stiffer, more translucent, has better barrier properties but needs high sealing temperature. Polypropylene (PP), are better suited for confectionary packaging because of better barrier properties, clarity than polyethylenes and superior machineability but lack good sealability. This problem could be overcome by applying PVDC and vinyl coating. Apart from this poly vinyl chloride (PVC), polyesters (PET) and polyamide (PA) and metalized films are also being used in certain confectionary products. For long term storage toffee and caramel are kept at room temperature (25-30°C) at low relative humidity.