Module 3. Bakery and snack foods

Lesson 11

TECHNOLOGY OF BREAD MAKING

11.1 Introduction

Bread baking is one of the most important discoveries of mankind. Bread is made by baking dough which has for its main ingredients wheat flour, water, yeast and salt. Other ingredients which may be added include flours of other cereals, milk and milk products, fruits, gluten, etc. When these ingredients are mixed in correct proportions two processes commence: (i) the protein in flour begins to hydrate and forms a cohesive mass called as gluten (ii) evolution of carbon dioxide gas by action of the enzymes in the yeast upon the sugars. Three main requirements in making bread from wheat flour are formation of gluten network, aeration of the mixture by incorporation of gas, and coagulation of the material by heating it in the oven.

11.2 Principle of Bread Baking

There are three technological principles involved in baking of bread:

1) Conversion

of starch: Wheat flour starch is partly converted into the sugar, which is

being used by yeast during fermentation producing alcohol with simultaneous

release of CO2 gas is responsible for porous, open honeycomb texture

of the baked bread.

2)

Mechanical stretching: The hydrated

wheat protein forms gluten fibers, which are stretched mechanically to obtain a

fine, silky structure. This structure remains permanent when the protein is

denatured during baking. The stretching of gluten is partially achieved by

development of CO2 gas during yeast fermentation and partly by

mechanical mixing.

3) Flavour

development: Bread flavor is because of the alcohol and other compounds

generated during yeast fermentation, together with flavor compounds formed

during baking.

11.3 Ingredients and their Functions in Bread Making

11.3.1 Essential ingredients

11.3.1.1 Flour

Flour is essential to the structure of dough and subsequently the bread. Gluten (Gliadin and Glutenin) is the principle functional protein of wheat flour. Gluten forms fibrillar frame work when hydrated and mechanically worked. Thus the wheat flour is converted into cohesive, elastic, extensible dough. This viscoelastic three-dimensional gluten network retains gas formed by sugar fermentation and contributes to structure of dough and bread.

Starch plays important role in dough during baking. When heat is applied, gas cells expand gluten networks stretches, starch granules take up water and get partially gelatinized. This viscous paste sets to gel after baking. Satisfactory protein content for bread flour is 11 – 13% and moisture content not more than 14%.

11.3.1.2 Water

Water hydrates gluten proteins during mixing, gelatinizes starch during baking and serves as a dispersion medium for other ingredients such as yeast. Quality of water such as pH and hardness of water play important role in dough formation. Excessively alkaline water can retard the activity of yeast enzymes. Hard water containing calcium and magnesium ions, may have a “tightening” effect and soft water a “loosening” effect on dough.

11.3.1.3 Yeast

Yeast produces carbon dioxide and ethanol by fermentation of fermentable sugars. During fermentation it also helps in formation of flavour precursors. Rate of fermentation of dough by yeast is controlled by temperature, nutrient supply, water, pH, sugar concentration, salt and level and type of yeast. Generally two type of yeasts are used in baking: Compressed yeast and dried yeast. Both the types consist of living cells of Saccharomyces cerevisiae.

11.3.1.4 Salt

Salt acts as flavour enhancer and helps control the fermentation by yeast. It also toughens the gluten and gives less sticky dough.

11.3.2 Optional ingredients

The optional ingredients used in bread formulation are listed in Table 11.1 along with their functions.

Table 11.1 Functions of optional ingredients in the bread

|

S.N. |

Ingredient |

Example |

Function |

|

1. |

Mineral yeast food |

|

· Controls fermentation |

|

i. |

Water conditioner (Calcium salts) |

Calcium acid phosphate Calcium sulfate Calcium peroxide |

|

|

ii. |

Yeast conditioners (Ammonium salts) |

Ammonium chloride Ammonium phosphate Ammonium sulfate |

|

|

iii. |

Dough conditioners (Oxidizing agents) |

Potassium bromate Dehydro ascorbic acid Potassium iodate Dicalcium phosphate |

|

|

2. |

Sugar |

Sucrose High fructose corn syrup |

· Energy source for yeast · Fermentable carbohydrate · Flavour – Sweetness and flavour compounds generated during fermentation and baking · Crust colour: Caramelization and non enzymatic browning · Delays staling of bread by increasing hygroscopicity and thus tenderizing the crumb |

|

3. |

Shortening |

Edible fats and oils containing dough conditioners and emulsifiers (Calcium stearoyl-2-lactylate, sodium stearoyl-2-lactylate, Mono and diglycerides, Polysorbate 60, Succinylated monoglycerides, Ethoxylated monoglycerides, Sucrose esters) |

· Facilitates dough handling and processing · Eases gas cell expansion in dough · Increases loaf volume · Improves crumb grain uniformity and tenderness · Lubricates slicing blades during slicing · Extends shelf-life |

|

4. |

Dairy products |

Skim milk powder Sweet cream butter milk Sweet dairy whey Caseinate Whey protein concentrate |

· Nutrition: high in lysine and calcium · Flavour enhancement · Improves crust colour (Maillard browning) · Buffering effect in dough and liquid ferments |

|

5. |

Mold inhibitors |

Sodium propionate Calcium propionate Sodium diacetate Potassium sorbate Vinegar |

· Retardation of spoilage due to mold growth · Retards formation of “rope” by B. subtilis |

|

6. |

Wheat gluten |

Wheat gluten |

· Enhances dough strength · Increases water absorption · Increases bread loaf volume · Imparts greater stability to the dough during fermentation |

|

7. |

Malt |

Malt flour Malt extract Dehydrated malt extract |

· Contributes fermentable sugar (maltose) · Enhances flavour · Contains amylases, which converts starch to sugar · Improves crust colour · Extends shelf-life because of improved water absorption |

|

8. |

Enzyme supplements |

|

|

|

i. |

Amylases

|

Cereal amylase: barley malt Fungal amylase: Aspergillus oryzae Bacterial amylase: B. subtilis |

· Convert starch to sugar · Aid crust colour · Improve dough handling · Extend shelf-life |

|

ii. |

Protease |

Fungal protease: Aspergillus spp. Bacterial protease: B. subtilis Bromelain (Fruit) |

· Weaken dough due to cleavage of peptide bonds in wheat protein · Reduce dough mixing time · Increase pan flow |

|

iii. |

Lipoxygenase |

Soya |

· Whiter bread crumb · Improves shelf-life · Increases dough strength and mixing dough tolerance |

11.4 Bread Manufacturing

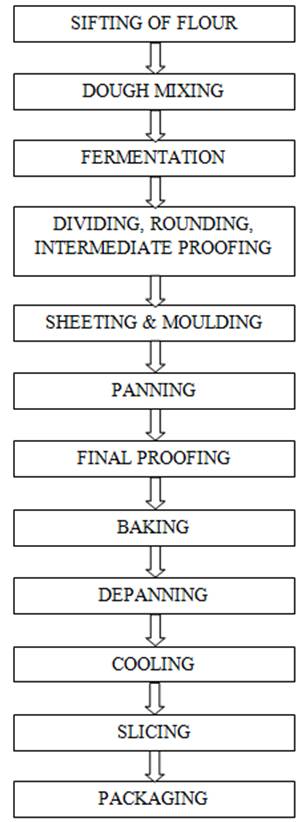

Production of bread consists of number of steps. The flow diagram for manufacture of bread is given in Fig. 11.1 and Fig. 11.2.

The first step of bread making involves sifting of flour to remove any foreign matter and coarse particles, and to aerate and make the flour more homogeneous. The next step is dough mixing, which is accomplished by various methods of preparation of dough. Once the dough is formed, it is divided into pieces of requisite size. The divided dough is rounded to a ball shape and then passed through intermediate proofer, where the roughly stretched gluten fiber get time to recover their extensibility so that they can be moulded well without breaking the surface skin. After intermediate proving, the dough is passed through a set of pairs of roller to form a sheet. The sheeted dough is now passed through pressure board to get moulded into cylindrical shape.

The moulded dough pieces are then placed into greased individual bread baking tins. The panned dough pieces are then passed through final prover under controlled temperature and humidity. After complete proofing, the dough tins are transferred to the baking oven. Once baking is completed, the breads are de-panned, cooled and then sliced. Sliced breads are then packaged in suitable packaging material, generally polypropylene pouches.

Fig. 11.1 Flow diagram for bread manufacture

11.5 Methods of Bread Making

Based on the way dough is prepared, different methods of bread making can be broadly grouped into three: Conventional (bulk fermentation) dough development methods, mechanical dough development methods, chemical dough development method.

The major production methods used in wholesale bread production are the sponge and dough method, liquid fermentation method, straight dough method, no-time dough method, frozen dough method, continuous bread manufacturing, Chorleywood bread process.

11.5.1 Sponge and dough process

This is the most common commercial method used to manufacture bread. Sponge is prepared by mixing flour with water and yeast and allowed to ferment for a certain period of time. Subsequently balance flour, water and other ingredients are added to sponge. The ratio of sponge to dough is maintained at 70:30. After through mixing, dough is allowed to ferment for 3 – 5 hours at 30°C. The dough is then divided into pieces to yield bread loaves of desired weights. The dough pieces are then rounded, given rest period of 7 min and then sheeted, shaped and panned. The proofing of dough is carried out for 55 min at 42°C and 85% relative humidity (RH). The bread loaves are subsequently baked at 230°C for 18 – 20 min, cooled, sliced and wrapped.

11.5.2 Liquid fermentation process

Principle of this method is same as sponge and dough method, except that it uses a liquid instead of plastic sponge.

11.5.3 Straight dough method

All formula ingredients are mixed in single step at the mixer. The dough is mixed to a full gluten development and then fermented. Fully fermented dough is then handled same as sponge and dough method. This procedure is used by retailers or for specialty breads.

11.5.4 No-time dough process

This method is same as straight dough method, except mixing is carried out mainly mechanically by the action of high-energy input of special mixers. This mixing step is further enhanced by addition of various ingredients such as L – cysteine, yeast foods and proteolytic enzymes. The mixed dough is given short or no fermentation, then divide, rounded, moulded, proofed and baked. This method is suited for frozen dough manufacturing and retail bakeries.

11.5.5 Frozen dough method

Frozen doughs are used for baking in in-store bakeries. Frozen doughs are generally manufactured by a straight dough method. The dough units are immediately frozen using fast freezers to a core temperature of – 7°C, then stored at – 15°C. In in-store bakeries the doughs are deposited in a retarder at 1 – 4°C, then proofed at 32 – 43°C for 75 – 90min and baked. The expected shelf-life of frozen dough is about 8 – 12 weeks.

11.5.6 Continuous bread process

In this method the dough is prepared continuously and automatically in enclosed chamber. This process introduced in United States is represented by two systems: Do-maker process developed by John C. Baker and Amflow process which was introduced by American Machine and Foundry Co. In both the methods high amounts of oxidants are required due to high mechanical dough abuse during mixing and extrusion operations.

11.5.7 Chorleywood process

This process is used widely world over. It was originated in United Kingdom. The basic principle is closed high-speed mixer with special mixer configuration blades. The mixing is generally accomplished under vacuum. Two types are mixers are widely used: Tweedy and Stephan. The oxidants used in this process are ascorbic acid and azodicarbonamide (ADA).

11.6 Staling of Bread

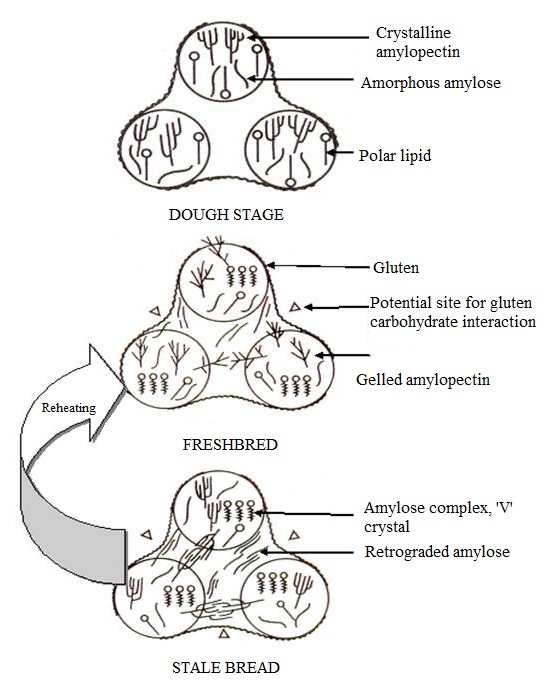

Bakery products undergo physic-chemical, sensory and microbial changes during storage. The generic term for this is ‘staling’. Staling means series of changes that causes a decrease in consumer acceptance other than that resulting from the action of spoilage microorganisms. The typical characteristics of staling of bread are that, the crust looses crispness and crumb becomes firm. Other associated changes are loss of flavour and emergence of stale flavor. The main cause for staling of bread is moisture migration from crumb to crust. The complete mechanism of staling of bread is not yet understood. But the theory given by Schoch and French is the most accepted one. According to this theory, retrogradation of starch is the underlying reaction of staling.

Starch gelatinizes during baking and amylose is leached out. Amylose component crystallizes upon cooling and impart firmness to the bread, which is an indication of freshness of the bread. During storage amylopectin retrogradation proceeds slowly and causes firming of the bread. This process is heat-reversible because retrograded amylopectin can be reverted to its amorphous state, which reduces firmness. Zobel and Kulp have described physico-chemical changes of the starch granule which is shown in Fig. 11.3

11.7 Ropy Bread

Bread ropiness is caused if the bread dough is contaminated with B. mesentericus. The spores of the bacteria are not killed during baking. A sticky, gummy material which can be pulled into threads develops in the centre of the loaf within 1 to 3 days after baking. The bread also develops an off-flavour.

Fig. 11.3 Mechanism of bread staling