Module 5. Oilseed processing

Lesson 17

DEHULLING AND EXTRACTION OF OIL FROM

OILSEEDS, PROCESSING OF VEGETABLE OIL, PROCESSING AND UTILIZATION OF OILSEED

MEALS

17.1 Introduction

The major role of edible oils and fats in our diet is to supply energy. Fat provide 9 kilo calories for each gram consumed. Fat contain poly-unsaturated fatty acids (PUFA) which reduces blood cholesterol and is important in prevention of coronary heart diseases. They also contain essential fatty acids (EFA) which are required in the maintenance of normal growth, reproduction and skin permeability. Apart from these fatty acids, fats are the only source of fat soluble vitamins such as Vitamin A, D, E and K in our diet.

World’s five major annual edible oilseeds are soybean (Glycine max (L.) Merr.), cottonseed (Gossypium hirsutum L.), rapseed/canola (Brassica napus L. B. rapa L. and B. juncea L.), sunflower seed (Helianthus annuus L. var. marcocarpus DC.) and peanut/groundnut (Arachis hypogaea L.) Almost all oilseeds are processed commercially by oil expellers. Oilseeds are made up of tinny particles called cells. Oil glands are embedded in each cell which liberates oil on rupturing. Thus, the primary object of oilseed processing is to rupture the gland and cell wall which gives more yield of oil during processing. Recovery of oil (primarily triglycerides and phospholipids) from oilseeds is facilitated by rupturing the cell wall by heat and pressure during flaking, and by optional extrusion with an expander, followed by pressing or solvent extraction.

17.2 Extraction of Oil from Oilseeds

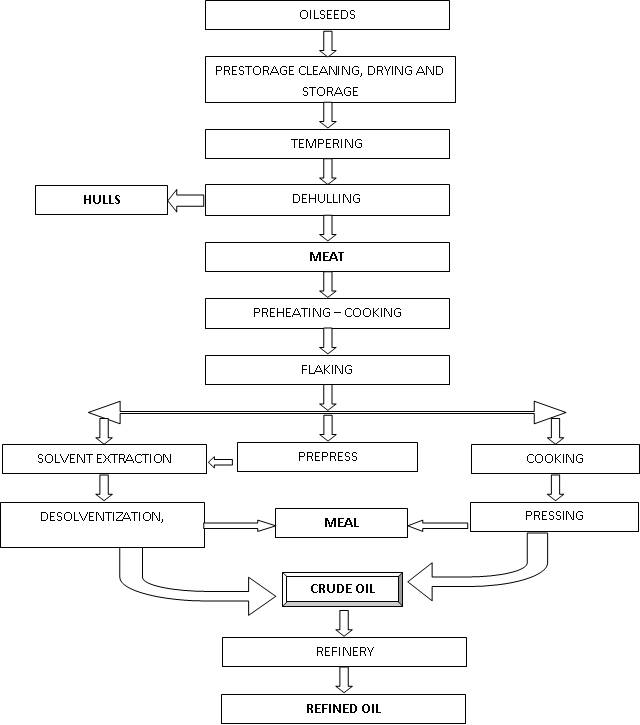

Extraction of oil is typically done by following methods listed in Table 17.1. A general oil extraction flow diagram is shown in Figure 17.1

17.2.1 Cleaning

Oilseeds received at mill may contain certain impurities entering from field, during storage and transportation, or accidentally. Frequently encountered impurities include: straws, chaff, sticks, weed seeds, other grains, shrunken and broken seeds, infected seeds, mud, dust, stones, metal objects, etc. Cleaning of oilseeds comprises removal of all the impurities mentioned above.

17.2.2 Conditioning/Tempering

The ground or flaked oilseeds are heated with live steam to about 90°C. The purpose of tempering is to facilitate oil recovery. The heat treatment ruptures all the cells, partly denatures the proteins and inactivates most of the enzymes. It is very essential to maintain the optimum temperature to avoid formation of undesirable colouring compounds and aromas. After conditioning and moisture adjustment to about 3%, the oil is obtained by pressing and/or solvent extraction.

17.2.3 Pressing

The oil is removed by pressure from an expeller or screw press. The residual oil in the resultant oilseed meal is about 4–7%. It is, however, more economical to apply lower pressures and to leave 15–20% of the oil in the flakes, and then to remove this oil by a solvent extraction process (“prepress solvent extraction” process).

Table 17.1 Oil extraction methods

|

Sr. No. |

Method of oil extraction |

Employed for |

% residual oil in meal/cake |

Remarks |

|

1 |

Solvent extraction |

Low oil seeds (less than 30% oil) |

0.5 – 1.0% |

Oil is solubilized by solvent (n-hexane). |

|

2 |

Full/Hard pressing |

High oil seeds (greater than 30% oil) |

4.5 – 7.5% |

Seeds are passed through continuous screw press. |

|

3 |

Prepress-solvent extraction |

High oil seeds (greater than 30% oil) |

0.75 – 1.25% |

16 – 20% oil is extracted by screw press and the cake is then treated with solvent to achieve further extraction. |

17.2.4 Extraction

The ground seeds are rolled into thin flakes by passing them between smooth steel rollers. The extraction is then performed using non-polar solvents such as food grade hexane, as a solvent (boiling point 60–70°C). In addition to n-hexane, it contains 2- and 3-methylpentane and 2,3-dimethylbutane and is free of aromatic compounds. Solvent removal from the raw oil-solvent mixture, called miscella, is achieved by distillation. The maximum amount of solvent remaining in the oil is 0.1%. The oil-free flakes are then steamed to remove the solvent (“desolventizing”) and, after dry heating (“toasting”), cooled and sold as protein-rich feed for cattle. The crude oil obtained either by pressing or solvent extraction contains suspended plant debris, protein and mucous substances. These impurities are removed by filtration.

Fig. 17.1 Flow diagram for oilseed extraction

17.3 Processing of vegetable oils

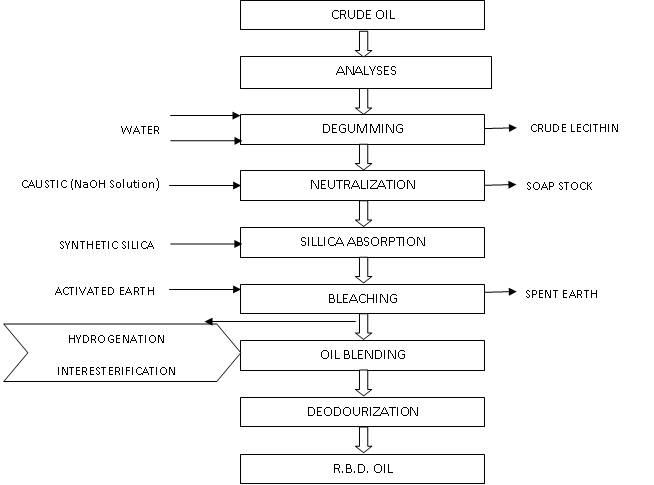

Many pathways exist for processing crude oil into various commercial oil and fat products (Fig. 17.2)

Fig. 17.2 Flow diagram of vegetable oil processing

17.3.1 Analyses of crude oil

Before starting processing, oils are brought from storage tanks into a ‘day tank’, which is thoroughly mixed and sampled for analyses to determine the treatments to be applied. These tests include free fatty acids, phosphorous, moisture, insoluble impurities and colour.

17.3.2 Degumming

Degumming is the process of removing phosphatides by hydration with water. The phosphatides must be removed to prevent darkening of the oil during the high temperatures of deodourization and in later applications like frying and to extend oil shelf life. Degumming is practiced for recovering crude lecithin for later purification. Approximate phosphatides content of the major crude oils vary between 0.5 to 3.5%.

Crude oil is heated to 60-80°C and soft water at the rate of 75% of the weight of phosphatides is added into oil, and hydration allowed to occur with the mixing for 30-60 min. Although the hydrated gums will settle by gravity, in commercial installations, separation is accelerated by use of decanters and disc type centrifuges. Simple water degumming typically reduces phosphorus content of soybean oil from 500-800 ppm to well under 50 ppm. Levels of 0-5 ppm phosphorus are desired in oils going to be deodourized. To obtain this, it may be necessary to solubilise the nonhydratable phosphatides by acid degumming. Phosphoric and citric acids are used to chelate and withdraw the divalent cations and restore phosphatide solubility in water.

17.3.3 Neutralization

Neutralization is the step of converting the free fatty acids in crude oils to soaps. It is some times called ‘alkali neutralization’ or ‘refining’. Sodium hydroxide is the most popular neutralizer used for refining of crude oils. Two continuous refining systems are used: long mix process and short mix process.

The long mix process uses a lower concentration of caustic and is conducted at ambient temperature 33°C with 8-15 minutes. Then the oil is heated to70°C, to assist breaking the emulsion and the mixture is passed through centrifuge.

The short mix process is conducted at 90°C, uses a more highly concentrated caustic, and a mixing and centrifuging time of less than 1 minute.

17.3.4 Silica absorption

In traditional refining, oil from primary centrifuge id washed with warm soft water to remove residual soap and passed through secondary centrifuge. In modern method degummed, caustic neutralized, partially vacuum dried oil is mixed with synthetic silica. Synthetic silica hydrogels, effective in removing 7-25 times more phosphatides and soaps than clay on a solid basis.

17.3.5 Bleaching

The objective of the bleaching is to remove various contaminants, pigments, metals and oxidation products before the oil is sent to the deodourizer. Types of bleaching material available include: natural earth, acid activated earth and activated carbon. A typical vacuum bleaching process is 20-30 minutes at 100-110°C and 50mmHg absolute.

17.3.6 Hydrogenation

Hydrogenation is the process of adding hydrogen to saturate carbon-to-carbon double bond. It is used to raise triglyceride melting points and to increase the stability against oxidation. Most of the catalysts that assist hydrogenation are nickel-based. Efficient hydrogenation requires cleanest possible feed stock and the purest, driest hydrogen gas possible. The catalyst must be completely removed by filtration before further processing of the oil.

17.3.7 Interesterification

Controversies exist about the healthfullness of trans fatty acids produced during hydrogenation. Interesterification is a technique for positioning or rearranging fatty acids on triglycerides. This technique is followed as a means of obtaining trans-free margarines, spreads and shortenings. Interesterification mainly uses sodium methylate, sodium ethylateor other catalysts ans is assisted by temperature manipulation. Position specific enzymes such as 2-glycerol and 1,3-glycerol position are also employed for interesterification. The catalyst must be deactivated and the resulting oil purified before further processing.

17.3.8 Chill fractionation

Chill fractionation is a process of chilling oil to a selected temperature to cause crystallization of a fraction. The crystals can be removed by vacuum belts or frame pressure filters equipped with inflatable air bladders.

Essentially all the palm oil is chill fractionated. The fraction seen most as palm oil is the olein.

17.3.9 Oil blending

Oil blending is an optional step, used primarily when oils with specific solid temperature profile are prepared. If blending does not occur, the oil may go directly from bleaching to deodourization.

17.3.10 Deodourization

The last treatment given to oil before leaving a refinery is deodourization to reduce its peroxide value to essentially zero. Deodourization is essentially steam distillation process for removing peroxides as well as flavours and odours from the oil. Soybean oil is deaerated, then deodourized in continuous deodourizers for 15-60 minutes at 252-266°C with an acsolute pressure of 1-6 mmHg, using stripping steam at the rate of 1-3% of the weight of oil.

17.3.11 RBD Oil

Some countries want characteristic flavours and colours left in their oils. In contrast, RBD (Refined, bleached, deodourized) oils are light coloured and bland regardless of the species. Supplier specifications generally are tighter than trade association specifications. Several suppliers offer soyben oil with <0.05% free fatty acids and 1.0 meq peroxide value.

17.4 Utilization of Oil Seed Meal in Food Formulations

Oil seed meal refers to coarse residue obtained after oil is removed from various oilseeds. It is relatively rich in protein and minerals and generally used as poultry and other animal feed. It may be broken up and sold or be ground into oil meal. Oil meal from certain seeds such as castor beans and tung nuts are toxic and are used as fertilizers rather than feed.

Oilseeds from which oil meal used as feed is produced include soybeans, peanuts, flaxseed (linseed), rapeseed, cottonseed, coconuts (copra), oil palm, and sunflower seeds. Cottonseed and peanuts have woody hulls and shells, which are generally removed before processing. The pressed cake from the production of cottonseed oil must also be processed to remove a toxic pigment called gossypol, before it can be used as feed for non-ruminants such as pigs and poultry.

17.4.1 Food uses of oil cakes

To cope up with protein deficiency malnutrition, cereal based products play a pivotal role as a vehicle for value-addition being consumed by masses. Defatted oil cake meal is widely used in various food formulations to improve quality characteristics and nutritional values.

The products in which oil cake meal are successfully used are shown in Table17.2.

Table 17.2 Uses of oil cake meal in food formulations

|

Sr. No. |

Food Product |

Results |

|

1 |

Comminuted meat products |

· Improved sensory quality · Improved yield |

|

2 |

Frankfurters |

· Batter stabilizing effect · Improved nutritional value |

|

3 |

Macaroni |

· Longer dough mixing time · Higher water absorption · Improved protein content and amino acids profile |

|

4 |

Bakery products |

· Improved the amino acid and mineral composition |