Module 2.

Meat and poultry processing

Lesson 23

PROCESSING OF MEAT AND MEAT PRODUCTS

23.1 Introduction

The meat processing involves the slaughter of animals and fowl, processing of the carcasses into cured, canned, and other meat products, and the rendering of inedible and discarded remains into useful by-products such as lards and oils. Meat is exposed to a series of wide range of processes viz. curing or preserving processes such as salting, wet pickling, drying, cooking and canning, sausage manufacture, ham curing. All these processing techniques are aimed at inhibiting the microbial spoilage and increasing the shelf life of the meat. Major principles involved in meat processing are use of heat, low temperature, smoking, modified atmosphere packaging and ionizing radiations. The methods of preservation are mainly grouped in three categories i.e. control by temperature, by moisture and by lethal agents (bactericidal, fungicidal etc.)

23.2 Preservation of Meat

23.2.1 Use of low temperatures

Chilling and freezing are most commonly used preservation system for meat and meat products.

a. Chilling

Chilling is most widely used technique to preserve raw and processed meat. Chilling preserves muscle tissue by retarding the growth of microorganisms and by slowing many chemical and enzymatic reactions. Storage temperature may vary from - 1.4 to 2.2°C for storage of beef for 30 days depending upon the number of microorganisms. Carcass should go to the cooler as soon as possible and its inner most part should be able attain below 10°C within 12 hrs of slaughter in order prevent undesirable off-flavours and bone taints due bacterial growth. An ideal temperature of storage for meat should 1°C above its freezing point.

During post mortem cooling and subsequent refrigerated storage, control of relative humidity (around 90%) is very important. The undesirable moisture is lost from the surface, the weight reduction becomes of economic important and meat pigments myoglobin might get oxidized to brown metamyoglobin. However, a small amount of moisture loss from the surface is desirable since this tends to retard growth of microorganisms.

b. Freezing

Freezing is an excellent process for preserving the quality of meat for long periods. Freezing is often used to preserve meats during shipment over long distances or for holding until long times of storage. Its effectiveness depends on ice crystal formation and rate of lowering of temperature. When the temperature of storage is below - 18°C, changes occur at a very slow rate in the muscle of warm blooded animals. Quality of frozen meat depends on various factors such as rate of freezing, packaging etc. When muscle tissue is frozen rapidly, small both intra – and extra – cellular ice crystals are formed which cause little damage to the meat structure. While large ice crystals are formed in slow rate of freezing causing compactness of muscle fiber. The process of denaturation can be accelerated with a resulting decrease in water holding capacity of tissue. Loss of water holding capacity of the muscle along with mechanical damage to cells by ice crystals is responsible in large parts of thaw exudates. To protect quality loss due to changes in protein, anti-freezing compounds or cryoprotectants i.e. polydextrose, polyphosphate are added to meat formulations. Rapid freezing can be obtained by using air blast freezers either on batch or continuous basis which employs -20 to -40°C cold air. Large size meat cuts are vacuum packaged to prevent lipid oxidation and discoloration due to formation of metmyoglobin. Retail meat is packed in low permeability films with better mechanical strength e.g. Sarlyn.

23.2.2 Use of heat

The canning of meat is a very specialized technique in that the procedure varies considerably with the meat product to be preserved. Since meat products are low acid foods so the rate of heat penetration is fairly low. Commercially canned meats can be divided into two groups on the basis of heat processing used ;

(a) Meats that are heat processed in an attempt to make the can contents sterile.

(b) Meats that are heated enough to kill part of spoilage organisms but must be kept refrigerated to prevent spoilage.

Processing temperature for shelf stable canned cured meat is 98°C. Treatment of meat surfaces with hot water to prolong the storage time has been suggested. Although this may result in loss in nutrients and damage in colour. Actin is the most heat labile muscle protein becoming insoluble at 50°C. Denaturation of muscle proteins decreases their water holding capacity. This decrease in water holding capacity may produce desirable juiciness, Provided free water is not expelled from the tissue. During heating, fat is melted. Adipose tissue cells are ruptured and there is a significant redistribution of the fat. When meat is eaten warm, the melted fat serves to increase palatability of the product by giving desirable mouth feel, especially at the end of chewing period, when most of the aqueous juices are lost. Myoglobin also undergoes denaturation. The red pigment heme is oxidized to brown pigment hemin. Canned meat loaf can be manufactured substituting a part of the meat with high calcium coprecipitate. It is observed that 20% meat can be replaced with high calcium milk protein coprecipitate in chicken meat loaf without affecting the quality of the end product.

23.2.3 Dehydration

Deprivation of available moisture (reduction of water activity) for microbes not only prevent their growth but also kills them, thus results in increased shelf life and better quality product. Water may be made unavailable either by dehydration, freeze drying or by increasing exrtacellular osmotic pressure as is done in curing. Drying meats can be successfully employed for both raw and cooked meat. However, the quality of the final reconstituted product is superior when meat is cooked prior to dehydration. There is a loss in native structure of protein as measured by loss of water holding capacity during temperature from 0 to 20°C. This is caused by denaturation of sarcoplasmic proteins. The next major loss in water holding capacity begins in the temperature range of 40 – 50°C due to denaturation of contractile proteins. Collagen is rapidly converted to gelatin at around 100°C. Texture is most severely altered by dehydration. The tough texture of dehydrated meat can be overcome by preparing products of intermediate levels of water.

23.2.4 Smoking

Smoking is often used with salting and curing. It gives desired flavour, aroma and aids in preservation. It was noted that preservative substances added to the meat together with the action of heat during smoking have a germicidal effect and that drying of the meat together with chemicals from the smoke inhibit microbial growth during storage. Smoke consists of phenols, alcohols, organic acids, carbonyl compounds and hydrocarbons. The desirable effects of smoking of meat can be listed as below:

· Meat preservation through aldehydes, phenols and acids (anti-microbial effect)

· Antioxidant impact through phenols and aldehydes (retarding fat oxidation)

· Smoke flavour through phenols, carbonyls and others (smoking taste)

· Smoke colour formation through carbonyls and aldehydes (attractive colour)

· Surface hardening of sausages/casings through aldehydes (in particular for more rigid structure of the casing)

Production of smoke

Smoke is produced by burning of wood or its saw dust which consist of 40-60% cellulose, 20-30% hemicelluloses, 20-30% lignin. A temperature gradient exists during thermal decomposition of wood. Outer surface temperature is generally above 212oF during dehydration process. Co, CO2 and volatile medium chain organic acids e.g. acetic acid are released during dehydration and distillation process. When internal moisture level reaches to zero, the temperature rapidly rises to 570-750°F. Once the temperature falls within this range thermal decomposition occurs and smoke is given off.

Nature of smoke

Although the smoke at the point of generation exists in a gaseous state, it rapidly goes into a vapor & particle phase. The vapor phase contains the more volatile component & is largely responsible for the characteristic flavor & aroma of smoke. As soon as smoke is generated numerous reactions and condensation occurs. Aldehyde & phenol condense to form resins which represent about 50% of the smoke component & are believed to provide most of color is smoked meats. Polyphenols are also formed by condensation.

The amount and ratio of smoke deposition on the product is influenced by smoke density, smoke house air velocity and its RH, and surface of product being smoked

Cooking during smoking

Cooking is often done simultaneously with smoking of meat. In fact cooking is often more important than smoking in meat processing. Cooking equines careful control of the smoking and heating process to give best results.

Liquid smoke preparations

Liquid smoke is used by some processors. It is sprayed on the product before cooking. It has some positive effects over natural wood smoke.

(1) It doesn’t require the installation of a smoke generator and which usually requires a major financial outlay.

(2) Process is more repeatable, as the composition of liquid smoke is mane constant.

(3) Liquid smoke can be prepared so the particle phase is removed and thereby possible problems from the carcinogens can be alleviated.

Liquid smoke is generally prepared from hardwoods; The final product is composed primarily of the vapor phase & contains mainly phenols, organic acids, alcohols & corbonyl compounds. They don’t contain poly hydro carbons (PHC).

The there are two types of smoking cold at 15 to 18°C (up to 26°C) and hot temperatures of +60 to 80°C. Cold smoking is used for fermented meat products (raw-cured ham, raw-fermented sausage) and precooked-cooked sausage (liver and blood sausages). Hot smoking is used for a range of raw-cooked sausages, bacon and cooked ham products.

23.2.5 Modified atmospheric storage

Fresh meat held at refrigerated temperature has a limited shelf life because of microbial growth. Modified atmosphere refers to the adjustment in the composition of the atmosphere surrounding the product. At higher concentration of CO2 surface browning of meat occurs due to the oxidation of myoglobin and hemoglobin pigments to ferric state. The most desirable concentration of CO2 to use in a modified atmosphere is a compromise between bacterial inhibition and product discoloration.

23.2.6 Ionising radiation

Ionising radiation constitutes the potentially useful form of preservation. Besides from its desirable ability to inactivate micro – organisms, it also has the undesirable effect of altering meat pigments. Sterilizing doses of ionizing radiation results in the breakdown of various lipids and proteins to often undesirable odours. Tenderization of muscle may also occur during this treatment. Temperature of ≤ 80°C or below greatly reduces undesirable effect without affecting lethal effect on microorganisms. Generally enzymes are not inactivated by irradiation treatment, it is necessary to heat approximately 70°C prior to irradiation and storage.

23.3 Processing of Meat Products

23.3.1 Comminuted meat products

Comminution is the mechanical process of reducing raw materials to small particles called as minced meat. Depending upon the final use of the communited meat the degree of comminution is done which differs among various processed products and is often a unique characteristic of a particular product ranging from very coarsely comminuted (to produce non-emulsified sausages like salamis and summer sausages), to finely comminuted, (to produce emulsified sausages like frankfurters, bologna, etc). Sausages are usually defined as comminuted seasoned meats, stuffed into casings; they may be smoked, cured, fermented and heated. They are made from any edible part of the slaughtered, veterinary-inspected animal, and a series of nonmeat ingredients.

a. Sausages

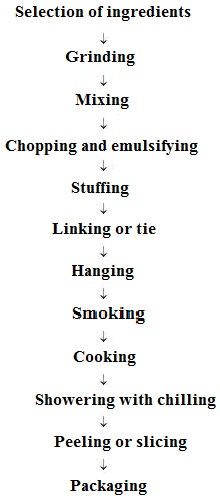

Sausages are meat products that are salted & usually seasoned or spiced and are an example of comminuted meet products that are generally recognized as emulsified, stuffed, linked, smoked, and cooked meat products. Based on the product characteristics and processing methods, they are broadly divided into three categories: fresh sausages, cured sausages and fermented sausages. In all cases meat is communited to reduce meat and fat particle size (grinding, mincing, chopping, or flaking), mixing with ingredients, stuffing into specific casing, linking to obtain specific lengths and finally, packaging. Sausages might be of ground and emulsion type. In the ground variety of sausages discrete particles of meat are seen on the other hand, in emulsion type sausages fat is emulsified & stabilized by lean component. Sausages were developed to utilize low- quality meats such as trimmings head, shoulder & by- products of the meat. The processing of sausages is a continuous sequence of steps (Fig 23.1), which are all equally important.

Fig. 23.1 Process flow diagram of sausages manufacture

i. Selection of Ingredients

Sausage ingredients include:

· Meat - based on consideration of fat/protein; moisture/protein and myoglobin concentration

· Moisture - added as ice at time of chopping in a number of fresh and smoked sausages

· Curing ingredients - salt, sodiuim nitrite and/or nitrate and sugar

· Seasonings - may include spices, such as black peper, paprika, mace and cinamon; herbs that may include thyme and savory; vegetables such as garlic and onion and other substances, such as flavor enhancers

· Fillers and binders - occasionally used to improve color, binding properties, slicing characteristics, altering flavor or reducing costs

· Ascorbic acid - used to improve color in smoked sausages

· Other additives - may include liquid smoke

Milk protein have been utilized as fillers, binders and extenders in cooked, comminuted meat products to reduce cook shrink and formulation cost, as well as to improve emulsifying capacity, emulsion stability, water binding, potential nutritive value and slicing characteristics. These proteins significantly increase the gel strength of meat proteins and it has been shown that there has a synergistic effect between milk proteins and salt soluble meat proteins, through covalent cross linkages.

Addition of caseinate stabilizes the meat emulsion as required in the sausage mix. It thickens the gravy during frying and prevents it running out, but excess incorporation of caseinate may result in drying up of the sausages. Further addition of water absorbent materials becomes essential when sodium caseinate concentration in sausages exceeds 5%. The greater water holding capacity, lower viscosity and lower cooking losses of sausage batters containing 2% sodium caseinate in comparison to all meat control were observed.

The coprecipitates have good potential in various meat products such as frankfurters, sausage batter and luncheon meats as meat replacers or extenders. Sausage acts as a good medium for the use of coprecipitates. The finely, dispersed dairy protein matrix in sausages also can act as a moisture binding agent, thus, developing the desirable chewy texture besides controlling shrinkage during storage and deformation while slicing. Addition of milk coprecipitate in combined boiled sausages resulted in increased pH, reduced nitroso pigments and increased residual nitrites content in the end product. It is found that both high and low calcium coprecipititates improved the emulsifying capacity, emulsion stability and water holding capacity of meat emulsion in fresh sausages at the 20% replacement level. Supplementation with dairy coprecipitates into boiled beef pork sausage batters up to 30% of meat protein yields emulsion with increased pH, enhanced water binding ability and improved adhesion properties.

ii. Grinding

Meat chunks of variable size and shape with variable fat contents are ground to form uniform cylinders of fat and lean. The screw feed in the barrel of the grinder conveys the meat & presses it in to holes of the grinder plate. The rotating blade cut the compressed meat and aids in filling the grinder plate holes.

iii. Mixing

Cylinders of fat and lean obtained by grinding are tumbled in a mixer to give a uniform distribution of fat and lean particles. This can be used for coarse ground sausages or for emulsion type sausages by utilizing a chopper or emulsifier and with suitable additions of required ingredient to obtain the desired texture & uniformity of composition.

iv. Chopping

It is often used as a means of batching the sausage mix, the mixed batch being transferred to an emulsifier or acquiring the desired texture.

v. Emulsifying

This machine combines the principle of grinding and chopping. Emulsifier machine handles large volumes of meat rapidly to produce a desired texture. Speed of handling material and high degree of disintegration of meat tissue help in obtaining desired textures. In the preparation of sausage, the protein and water of the meat mixture form a matrix than encapsulates the fat portion. In a meat emulsion the protein myosin acts as the primary emulsifying agent. The addition of salt to the product is to release the myosin from the muscle fiber. The emulsion is generally formed by mixing the meat with salt and other ingredients in a chopper, which aids in disrupting the fibers and facilitates the release of myosin.

vi. Stuffing

Sausage emulsion also known in the trade as mix sausage dough or batter is transferred to stuffers for extending the mix or emulsion into casings. At this point, the size and shape of the product is determined. Generally three type of stuffing devices are used.

· Piston

· Pump

· Combination of piston & pump

In the past, the casing of the sausages were made from animal casings, however this was a limiting factor for the production of sausages. Today, the casings are made of cellulosic and regenerated collagen. The limiting factor now, is the supply of meat and the cost of it. Fermented sausages are further subjected for the fermentation and maturation. Fermentation of meat constituents results in flavor development, improvement of shelf life and improved quality and food safety. Sausage batter is inoculated with the started bacteria composed of selected lactic acid bacteria (LAB) i.e. homofermentative lactobacilli (Lb pentosus, Lb plantarum, Lb sake, Lb curvatus), pediococci (Pediococcus acidilactici, Pediococcus cerevisiae) and gram positive catalase positive cocci (GCC) i.e. non-pathogenic, coagulase-negative staphylococci (Staphylococcus carnosus, Staphylococcus xylosus, Staphylococcus piscifermentans) . Small manufacturers use spontaneous fermentation without adding starter culture.

vii. Linking and tying

After the emulsion is stuffed in to casings, the encased mass is tied with thread of fastened with metal clips. In the case of small sausages such as Frankfurters stuffed casing are twisted or drawn together to produces links either by hand or with mechanical devices.

Large sausages items are tied or slipped on one end with a hanging tie and suspended from a smoke stick or hook so the entire surface is free from contact with the equipment. This permits a good flow of air around the sausage in the smoke house and prevents touch marks and spotting due to contact with adjacently hanging product.

viii. Smoking & cooking

The draped smoker picks are placed on smoke trees or trolleys with 12-18 specs per tree. The smoke house operation is essentially a specialized drying and cooking operation in which sausage emulsion is coagulated. Encased sausage at the time of introduction in to the smoke house usually has an internal temp of 60-70ºF. During cooking this rises to 155 to 160ºF.

ix. Chilling

After smoking and cooking the product is showered with cold water and than chilled by refrigeration chilling is frequently done with a brine solution by dipping or spraying the products. (a 6% salt brine) balanced within leaching of salt from the sausage and imbibing of water by the sausage.

x. Peeling & packaging

After properly chilling the product usually to an ultimate temp of 35 to 40ºF, the cellulosic casings on frankfurter and slicing bologna are removed. This is known as the peeling operation.

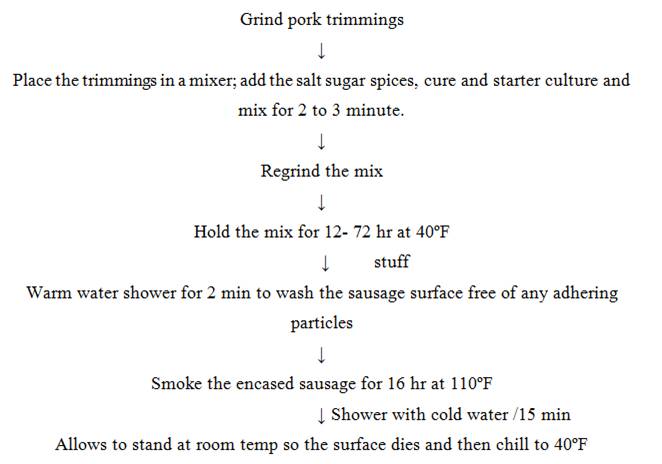

b. Semi dry sausages

Semi dry sausages are usually made from pork or beef or a mixture of the two and are characterized by a moisture content ranging from 40- 45%, e.g. summer sausage, Göteborg Sausage, Cerevelat, Thuringian, Holsteiner. They have excellent keeping quality with need of little refrigeration because

(1) Some reduction in microbiogical contamination is achieved in the cooking process

(2) A high salt to moisture ratio contributes to retarding bacterial growth

(3) A low pH (5.3 or less) provides the tangy flavor and serves a protective food and good keeping quality is achieved with a pH of 4.8 to 5.0 and with a total acidity of 0.75 to 1% lactic acid.

Fig. 23.2 Manufacturing method of semi-dry sausages

c. Dry sausages

Semi-dried sausages are smoked and cooked to varying degrees, whereas dry sausages are not cooked and only with some products smoke is applied. The manufacture of dry sausages is more difficult to control than that of semidried sausages. Overall processing time may require up to 90 days. As a result of this prolonged holding the sausages are vulnerable to chemical, microbiological degradation. However, when prepared properly the finished sausages are usually stable and can be held with little or no refrigeration. Examples of dry sausages are Geneva salami, Pepperoni, mortadella etc.

23.3.2 Cured meat products

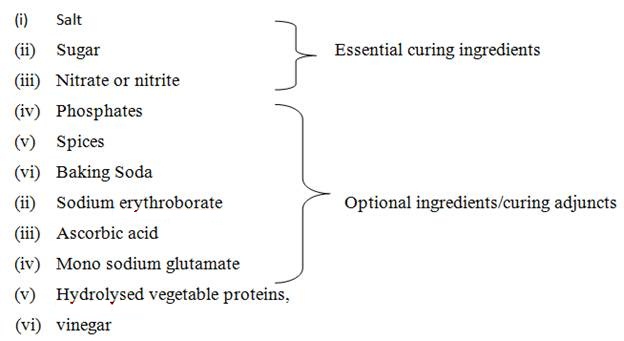

Curing of meat involves the essentially addition of sodium chloride, sodium nitrite or sodium nitrate and adjuncts to meat for increasing shelf-life and to obtain desirable colour and flavour. Sugar may or may not be added along with other ingredient to improve flavour. Curing can be done for both raw/cooked meats cut products as well for comminuted meat products e.g. sausages and similar preparations. Most popular raw cured meat includes ham and bacon which are pork products. However, the technique can be applied to any meat group.

23.3.2.1 Ingredients

used in curing

Commonly used salt sodium chloride (occasionally KCl) is most essential ingredients and it significantly inhibits growth of microorganism including Clostridium botulinum due to increase in the osmotic pressure of the medium and dehydration of the muscle. Salt if used alone results in dark coloured, unpalatable dry harsh and salty product. Therefore, it is recommended to be used in combination with sugar and nitrite and nitrate. Salt should be of good quality. Generally dry salting utilizes higher levels of salts; however, acceptable level of salt is about 3% for most of the meats and about 2% for bacon. Nitrite/nitrate has as well a small inhibitory effect on C. botulinum. However, it plays very important role in colour fixation of the cured meat. On the other hand sugar contributes to flavour and colour development due to mailard browning and also helps in increasing shelf life by controlling of bacterial growth. Endogenous low molecular weight components in the sarcoplasma of the meat promote the formation of nitric oxide, myoglobin and nitrite decomposition.

23.3.2.2 Chemistry

of curing process and meat colour development

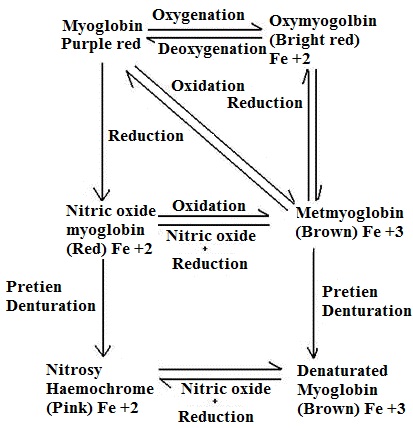

During the dry curing process salt in dry form is rubbed on the surface of the meat whereas in meat wet curing meat portion is immersed in the curing solution. The latest techniques of curing includes use of artery pumping, multiple needle injection, thermal or hot cures, tumbling, massaging, are employed to accelerate the curing the processes. In all cases, salt diffuses into the meat, causing some of the expelled protein to diffuse back in and the meat to swell. The salt – protein complex binds the water well thus the water holding capacity of proteins generally increases during curing. The final meat contains increased ash due to the absorbed salts. Generally salting results in darkening of the colour. To counteract the effect of salt nitrite/nitrates are added to salt which fix the desirable pink colour of the meat. In the curing, nitrite reacts with muscle pigment myoglobin to give purple-red coloured nitroso-myoglobin. On the cooking this is further converted into nitrosomyochrome which gives typical pink clour to the meat. It is further claimed that nitrite has a significant beneficial effect on the flavour of cured meats by preventing oxidation through the antioxidative activity of nitric oxide-myoglobin and s – nitrocysteine, a component found during the curing process.

Fig. 23.3 Colour fixation in meat

A major detrimental change that can occur in cured meat during storage is the oxidation of nitric oxide hemochromagen (pink) or nitric oxide myoglobin (red) to brown metamyoglobin (Fig. 23.1). The rate of oxidation increases with increasing oxygen content, therefore cured meat should be preferably packaged in a container from which oxygen is excluded.

Acceptable levels of nitrite used in meat and meat products are 100-200 ppm. The use of nitrite in cured meat may be hazardous if it is used at higher concentration with improper mixing, as it reacts with amines, especially secondary amines, to form N – nitrosamines, which may be carcinogenic. High temperature may also induce nitrosamine formation.