Module 7. Egg and egg processing

Lesson 27

PROCESSING

OF EGG

27.1 Introduction

Egg products are processed and convenience forms of eggs for commercial, foodservice and home use. These are refrigerated liquid products, frozen products, dried and specialty products. When shell eggs are delivered to the breaking plant, they are put into refrigerated holding rooms. Before breaking, they are washed in water at least 20 degrees warmer than that of the egg and spray-rinsed with a sanitizing agent. They may be moist, but not wet, when they are broken.

27.2 Classification of Egg Products

Egg is processed to produce convenience forms of eggs for commercial, food service and home uses. Egg products can be classified as follows

1. Refrigerated liquid products

Egg whites, Egg yolk, various blends of Yolk and white

2. Frozen products

Egg white, Egg yolk, Salted yolks, Sugared yolks, Whole eggs, Salted whole egg

3. Dried/Dehydrated products

Spray dried egg white solids, Instant egg white solids, whole egg or yolk solids, free flowing whole egg or Yolk solids (sodium silicoaluminate added as a free flowing agent).

4. Specialty products

Freeze dried scrambled eggs, Frozen precooked products like Egg patties, Fried eggs, crepes, Egg pizza etc.

Egg products are preferred to shell eggs by commercial bakers, food manufacturers and the foodservice industry because they have many advantages including convenience, labor savings, minimal storage requirements, ease of portion control, and product quality, stability and uniformity.

As per egg product inspection act all egg processing plants must follow below conditions:

· Pasteurization of all egg products is mandatory.

· Shell eggs used for egg products must be clean and of edible interior quality.

27.3 Frozen Egg Products

These include separated whites and yolks, whole eggs, blends of whole eggs and yolks or whole eggs and milk and these same blends with sugar, corn syrup or salt added.

27.3.1 Production of frozen egg

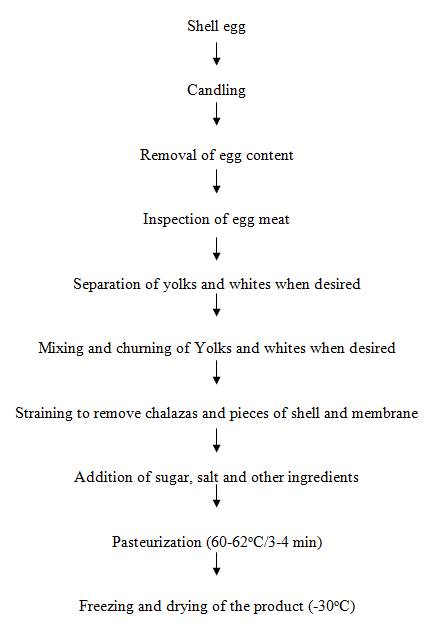

Fig. 27.1 Process flow chart for frozen eggs

Eggs are frozen to preserve them for use in food manufacturing. Before freezing, egg contents are separated from the shell and which may be frozen as whole egg, Egg yolk, Egg white or various mixtures of yolk and white.

Freezing plants are generally combined with egg breaking facilities where eggs are received, washed and dried. Then the eggs are broken to remove the egg content this could be done by hand or with the help of machines. While breaking the spoiled eggs are rejected as this could spoil the good product. The whole or separated eggs are mixed for uniformity, filtered to remove chalazae, membranes or bits of shell. Thus prepared egg contents are pasteurized at 60-62°C/3-4 min and filled into suitable container for freezing. Freezing generally is done in a sharp freezer room with circulating air at -30°C. Freezing may take about 48-72h.

Egg white and whole egg can be frozen as such without any additives but it is difficult in case of egg yolk. While freezing egg yolk becomes gummy and thick due to gelation. This can be prevented by the addition of 10% sugar or salt or glycerin 5%. Sugar yolk will be used by bakers, confectioners and salted yolk may be used by mayonnaise manufacturers. These ingredients should be dissolved in the yolk during mixing and prior to screening.

27.3.2 Production of spray dried whole egg

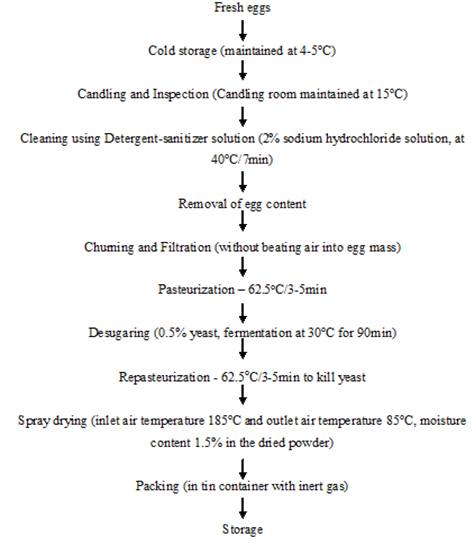

Fig. 27.2 Process flow gram for spray dried whole egg

The whites, Yolks and whole eggs may be dried by several methods, like spray drying, tray drying, foam drying or freeze drying. Egg white contains traces of glucose and galactose which react with egg protein leading to maillard browning. This discolors the dried egg white. Browning can be prevented by removing glucose through fermentation by yeast or with commercial enzymes. This is known as desugaring and this is practiced prior to the drying of all egg white.

27.4 Functional Properties of Egg Content

Eggs provide many desirable attributes as a food ingredient. The functional properties derived by egg contents are Coagulation, Emulsification and Foam formation.

27.4.1 Coagulation

The egg protein coagulates upon heating accompanied by binding of moisture and increase in viscosity. Heating causes denaturation of egg protein and gradually aggregates to form a three dimensional gel network. Thus eggs can be used as thickening agent in many food formulations mainly custards, cakes, pie fillings, cream puddings etc. The coagulation temperature is influenced by pH, salts, other ingredients and duration of heating. Egg white coagulates at 62 65°C and egg yolk at 65-70°C.

Heat coagulated protein

helps to hold the shape of the product in which these are used. Thus eggs are

used as binding agent in cutlets, chops etc.

27.4.2 Emulsification

The phospholipids i.e. lecithin and certain proteins present in egg acts as an excellent emulsifying agent. In mayonnaise egg yolk acts as an emulsifier to keep oil suspended in vinegar.

27.4.3 Foaming

Eggs when beaten form elastic films, which can trap air. Egg and egg products are good foaming agents. They produce large foam volume and relatively stable for cooking. Thus entrapped air expands during baking and gives fluffy and spongy product. Thus eggs are extensively used as leavening agent in baked products such as cakes and muffins.

27.4.4 Quality checks and storage of egg

Like any other food product, Eggs start deteriorating soon after it is laid. So it is very important to check the quality of the egg before its consumption. Good quality egg should possess following qualities once it is broken.

1. Yolk is firm and stands up in the centre of white

2. Egg white forms a definite ring around the yolk and thick white holds its shape

3. No blood spots are present

4. No bad odour

27.4.5 Changes occur in egg during storage

1. Increase in the size of air cell due to loss of moisture

2. Increased pH due to escape of carbon dioxide. pH increases from 7.6 to 9.7

3. Percentage of thin white increases, thus egg white loses its shape and runs easily.

4. Water passes from white to yolk, thus fluid content of yolk increases.

27.5 Indicators to Determine Spoilage in Eggs

1. White index:

White index = Height of thickest egg white portion/Egg diameter

Range: 0.08 0.1

2. Yolk Index

Yolk index = Height of Yolk/Yolk width

Range: 0.35 0.45

3. Houghs Unit (HU)

Commonly used index to check the egg quality

HU = Height of thick white/weight of Egg

For good quality egg HU is 72 and above and HU about 30 to 60 indicates poor quality.

4. Air cell size should be 2-3cm

27.6 Preservation of the Shell Eggs

Eggs can be preserved by 4 different methods

27.6.1 Wet immersion method

In this method only infertile, fresh, good quality eggs should be used

27.6.1.1 Lime sealing method

In this method saturated solution of lime water is used. Eggs are held in lime water for 14 -16hr, during immersion CO2 released from the egg combined with lime to form calcium carbonate which deposits and seals shell pores. Then it is removed and stored at room temperature. Such eggs can be stored for 3 -4 weeks at room temperature

27.6.1.2 Water glass method

10% solution of sodium silicate is commonly called water glass. In this method Water should be boiled and cooled to 24 26°C, to remove the dissolved CO2, before the addition of calculated amount of sodium silicate. Eggs are kept overnight and then removed and stored at room temperature.

27.6.2 Dry methods

27.6.2.1 Oiling

In this method the quality of eggs is preserved by sealing the shell pores using suitable oil and thus preventing evaporation of water, CO2 and other changes. Oiling can be done by Dip method or Spray method. Oiled eggs can be preserved upto 3 weeks at room temperature.

27.6.2.2 Gaseous atmosphere

Modified atmosphere packing of eggs proved to improve its shelf life. Maintenance of higher CO2 pressure surrounding the eggs prevent CO2 loss from the egg thus improves the egg quality.

27.6.3 Thermization or heat treatment methods

Fertile, fresh eggs can be preserved by this method. Eggs are thermo- stabilized by immersing it in boiling water for 3 to 5 min while keeping the water stirred constantly. This heat treatment coagulates the albumin very close to the shell and thus prevents CO2 loss. Thermized eggs can be stored at room temperature for 3-4 weeks.

27.6.4 Cold storage or refrigeration:

Eggs can be stored well for a long time up to 5 6 months at -1.1°C and 85-90% relative humidity. For storage up to 3 4 weeks a temperature of -12.8°C and relative humidity of 60-70% is sufficient.

References

Avantina Sharma, 2006. Food science and technology, IBDC publications, Lucknow

Vijaya Khader, 2001, Food science and technology, ICAR, New delhi.