Module 7. Channa

Lesson 15

CHANNA – DEFINITION AND PRODUCT

DESCRIPTION, METHODS OF PREPARATION

15.1 Product Description

Chhana is an acid coagulated product obtained from milk. The curd mass obtained when milk is coagulated with the organic acids such as citric acid, lactic acid at higher temperature and after subsequent drainage of whey, mass of curd obtained is called chhana. It looks off-white, tastes mildly acidic, and has characteristic spongy texture.

According to FSSR-1511 chhana means the product obtained from the cow or buffalo milk or a combination thereof by precipitation with sour milk, lactic acid or citric acid. It shall not contain more than 70.0 per cent moisture and the milkfat content shall not be less than 50.0 per cent on dry matter. Milk solids may also be used in preparation of this product.

Low fat chhana shall conform to the following requirements:—

(i) Moisture not more than 70.0 percent

(ii) Milk fat not more than 15.0 percent of dry matter:

Further it says that such low fat chhana shall be sold in sealed package only.

Chhana is mainly prepared from cow milk and used for preparation of varieties of Bengali sweets. About 4 to 4.5% of the total milk produced in India is used for chhana making. Chhana is used as a base for the preparation of a variety of sweets like sandesh, rasogolla, chamcham, rasomalai, pantoa, chhana murki, etc. Following table (Table: 15.1) depicts the chemical composition of chhana. Table 15.2 reveals the partitioning of milk solids in chhana and its whey.

Table 15.1 Typical composition of cow and buffalo milk chhana

|

Parameters |

Cow milk chhana |

Buffalo milk chhana |

|

Moisture % |

53.4 |

51.7 |

|

Fat % |

24.8 |

29.7 |

|

Lactose % |

2.2 |

2.3 |

|

Protein % |

17.4 |

14.4 |

|

Ash % |

2.1 |

1.9 |

|

pH |

5.7 |

5.4 |

(Source: R. P. Aneja et al.,

1502)

Table 15.2 Partitioning of milk solids in chhana

and its whey prepared from cow milk

|

Constituents |

Milk |

Chhana |

Chhana Whey |

|

Moisture (%) |

87.34 |

53.20 |

93.42 |

|

Fat (%) |

3.50 |

24.70 |

0.42 |

|

Protein(%) |

3.62 |

17.82 |

0.44 |

|

Lactose (%) |

4.86 |

2.20 |

5.12 |

|

Ash (%) |

0.68 |

2.08 |

0.60 |

|

T.S. (%) |

12.66 |

46.80 |

6.58 |

|

SNF (%) |

9.16 |

22.10 |

6.16 |

It is reported that chhana retains about 90%fat and protein, 50% mineral and 10% lactose of the milk from which it has been made and it also reported that, in chhana it is possible to recover 52 – 61% of milk solids originally being present in the milk.

15.2 Methods of Manufacturing

15.2.1 Traditional method of manufacture

Chhana has been prepared by boiling about 15-40 lit of cow milk in a steel pan. Acidic whey (previous day whey) added to boiling hot milk serve as coagulant with continuous stirring till the completion of coagulation. Contents poured over a muslin cloth held over another vessel. Whey is collected in a vessel. Muslin cloth containing curd mass washed with potable water by immersion process and allowed to drain for 30min to expel free whey.

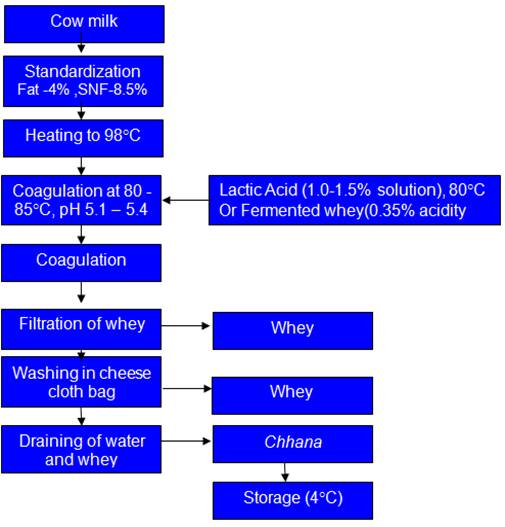

15.2.2 Industrial production of Chhana from cow milk

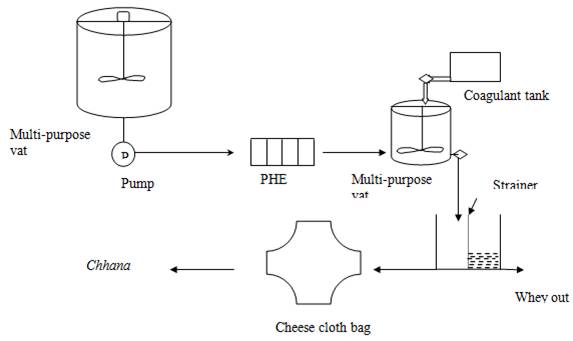

In industrial production, multi-purpose stainless steel vats or storage tanks are used for storage of milk, plate heat exchanger or steam jacketed kettle are used for heating of milk. Other process controls like temperatures of heating of milk, coagulation and coagulant are very precisely maintained as shown in flow diagram depicted below (Fig. 15.1). SS strainers with cloth lining are used to filter the whey out of coagulum.

Fig. 15.1 Flow diagram and chhana manufacturing process in organized plant

15.2.3 Mechanized system for chhana making

A prototype machine with a capacity to produce 40 kg of chhana/hour has been developed at NDRI, Karnal. The equipment consists of 1) Balance tank 2) Injection chamber 3) holding coil 4) Cooling chamber and 5) a strainer.

The standardized cow milk is pumped from balance tank at the rate of 250 lit of milk/ hr to an injection chamber where culinary live steam (at 1 kg/cm2 pressure and at the rate of 65kg/hr) is directly injected into the milk. The steam gets completely condensed in milk and the temperature is raised to 90-95°C. Thereafter, the milk is brought in contact with sour whey, the quantity of which is regulated in proportion to the rate of milk flow. The mixture of whey and milk is circulated through a holding coil (8m length X 10mm diameter) to facilitate complete coagulation of milk. The coagulated product along with whey is then pumped into a double jacketed cooling tank, where it is cooled down to room temperature. Finally the product is taken to mechanical strainer wherein inclined sieve situated to drain the whey thoroughly. Chhana with 55-65% moisture is discharged through the outlet and collected in the container. Drained whey is transferred to a holding tank for souring for subsequent use.

Fig. 15.2 Schematic diagram for mechanized chhana making

unit

- Balance

tank 7.

Double jacketed cooling tank

- Feed

pump

8. Inclined sieve

- Injection

chamber

9. Chhana collecting tray

- Sour

whey tank

- Mixing

regulatory valve

- Holding

coil

Recently, workers at Indian Institute of Technology, Kharagpur developed a continuous chhana-making unit of 60 L/h of milk capacity. The unit has a duplex plunger pump for dosing of milk and acid. Helical coil heat exchanger was used to heat milk prior to acid coagulation. It also consists of a vertical column that gives residence time for the separation of milk solids to chhana.