Module 10. Fermented dairy products

Lesson 23

DAHI PREPARATION

METHODS, QUALITY OF DAHI, PACKAGING, SHELF LIFE AND DEFECTS

23.1 Introduction

Fermentation is one of the simplest ways of preserving milk constituents for human consumption. Fermentation gives an acid taste to milk which is particularly refreshing in worm climate and also imparts certain therapeutic benefits originally absent in milk. Fermented dairy products have assumed prominent position in human diet in many regions of the world. Fermentation leads to partial breakdown of milk constituents and increases the digestibility of cultured milk products.

In Vedic literature also, we could find many references about fermented milk products some are listed below.

• Prasadjya – Dahi after dilution and churning, carrying butter grains in the liquid mass

• Payasya – Strained curd, when mixed with boiled milk, crystal sugar and fermented herbs

• Shrikarini – Consists of strained dahi, crystal sugar and spices

• Rasala -- Sugar and spiced curd

Some of the popular Indian fermented milk products are Dahi, Lassi, Chakka, Shrikhand, Mishti Dahi and Raita.

23.2 Product Description

Dahi is produced from heat treated milks after inoculation with certain species of lactic acid bacteria added to milk in the form of starter culture. Lactic acid bacteria added multiply, grow and produce lactic acid, acetic acid and carbon dioxide by utilizing lactose present in milk. Some bacteria uses citric acid of milk to produce certain volatile organic compounds mainly diacetyl, which is mainly responsible for flavor of dahi. Judicious combination of acid producing and flavour producing microorganisms in the starter helps in the production of Dahi with a firm body and good flavour.

23.2.1 Definition of dahi

Dahi or curd is a semi solid product, obtained from pasteurized or boiled milk by souring, using harmless lactic acid or other bacterial cultures. Dahi may contain additional cane sugar. It should have the same minimum percentage of fat and solids-not-fat as the milk from which it is prepared. Where Dahi or curd, other than skimmed milk Dahi, is sold or offered for sale without any indication of the class of milk, the standards prescribed for Dahi prepared from buffalo milk shall apply.

Table 23.1 FSSR(2011) and BIS standards of dahi

|

Characteristics |

FSSR(2011) |

BIS |

|

Acidity % lactic acid |

- |

0.6 - 0.8 |

|

Total Plate count |

Not more than 1000000/g |

|

|

Coliform count |

10 per g max |

10 per g max |

|

Escherechia coli |

Absent in 1g |

|

|

Salmonella |

Absent in 25g |

|

|

Shigella |

Absent in 25g |

|

|

Stephylococcus aurius |

Not more than 100/g |

|

|

Yeast and Mould |

100 per g max |

100 per g max |

|

Anaerobic spore |

Absent in 1g |

|

|

Listeria monocytogenes |

Absent in 1g |

|

|

Phosphatase test |

|

Negative |

|

Other requirements |

It should have the same minimum percentage of fat and SNF as the milk from which it is prepared. If no standards declared then standards prescribed for dahi from buffalo milk shall apply |

Dahi shall conform to the requirements of milk fat and MSNF, as laid down in FSSR, 2011 |

Table 23.2 Chemical composition of dahi

|

Components |

Whole milk Dahi |

Skim milk Dahi |

|

% |

% |

|

|

Water |

85-88 |

90-91 |

|

Fat |

5 – 8 |

0.05 - 0.1 |

|

protein |

3.2-3.4 |

3.3-3.5 |

|

Lactose |

4.6-5.2 |

4.7-5.3 |

|

Lactic acid |

0.5-1.1 |

0.5-1.1 |

|

Ash |

0.7-0.75 |

0.7-0.75 |

23.3 Method of Preparation

23.3.1 Traditional method

In traditional method of dahi preparation, milk is heated intensively to boil for 5 to 10 min and then it is cooled to room temperature. cooled milk is added with previous day’s curd or buttermilk, stirred and allowed to set undisturbed usually for overnight.

At halwai’s shop milk is considerably concentrated before being inoculated with starter culture. So that the total solid content of milk gets increased, particularly increase in the protein content of milk. Concentration of milk results in custard like consistency of dahi and keeps the product from wheying off.

23.3.2 Industrial method of making dahi

23.3.2.1 Selection of raw material

Production of cultured/fermented milk demands high quality raw materials with respect to physical, chemical and microbial standards.

23.3.2.2 Filtration/clarification

Fresh raw milk is heated to 35 to 40°C to aid clarification or filtration process then it is filtered to ensure that, milk is free from extraneous matter.

23.3.2.3 Standardization: Fat: 0 – 5%, SNF: 11 – 13%

Fat is standardized based on type of product ranging from fat free to full fat and SNF level is increased by min. 2% than that of milk. It is common to boost the SNF content of the milk to about 12% with the addition of skim milk powder or condensed skim milk.

Increased SNF inturn increases the protein, calcium and other nutrients and resulted with improved body and texture, custard like consistency. Higher milk solids prevent wheying off of the product during storage.

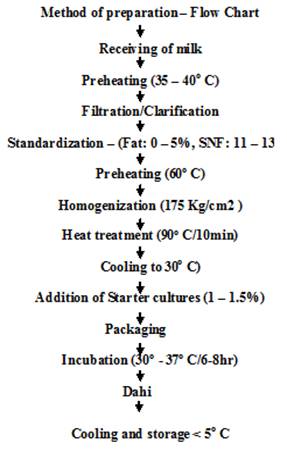

Fig. 23.1 Method of preparation of dahi

23.3.2.4 Homogenization: 175 Kg/cm2

The standardized milk is subjected to homogenization after heating to 60°C to increase the efficiency. Homogenization reduces the cream layer formation during incubation, Single stage homogenization with 175kg/cm2 pressure would be sufficient to improve texture of dahi.

23.3.2.5 Heat treatment: 9° C/23min

Milk intended for dahi or any other fermented milk product is given severe heat treatment i.e. 90°C for 10min.

Following are the benefits of high heat treatment

· Denatures and coagulates milk albumin and globulins which enhance the viscosity and produce custard like consistency

· Kills contaminating and competitive microbes

· Development of relatively sterile medium

· Removal of air form the medium – more conducive for the growth of culture bacteria

· Effective thermal breakdown of protein releasing peptones and sulfhydryl groups, this inturn provide nutrients to starter bacteria

23.3.2.6 Packaging and fermentation

The heat treated product mix is cooled to 37°C and it is inoculated with specific dahi culture at the rate of 1 to 1.5%. Starter culture is the most crucial component in the production of high quality fermented milks. Proper selection of culture strains decides the good quality of product. Dairy cultures are available in various forms like freeze dried, liquid and frozen forms. After the product mix is inoculated with dahi culture it is thoroughly mixed and filled into plastic cups, sealed properly to avoid any contamination and spillage of the product. Dahi is packed in food grade polystyrene and polypropylene cups in 100g, 200g and 400g pack sizes. Various packaging machines of upto 400cups/min speed are available to package cultural dairy products in different sizes. The packaged product should be stored at < 5°C for extended shelf lifeThus packed product is arranged in cases or crates and transferred to incubation room maintained at 37° to 42°C. The product mix is incubated till its pH reaches 4.4 to 4.5 and then it is cooled rapidly to less than 5°C by exposing the cups to high velocity cold air.

23.3.2.7 Storage

Dahi is normally stored at 4 – 5°C. Storage area should be maintained clean and tidy to avoid any cross contamination.

Table 23.3 Common defects in dahi

|

Sl No. |

Defect |

Probable Cause |

Remedy |

|

Flavor defects |

|||

|

1 |

Insufficient Flavor

|

Low citrate level in milk,

Low diacetyl content

|

Add 0.02 – 0.05% Sodium citrate prior to mixing the starter culture. Cool rapidly after culturing |

|

2 |

Oxidized flavor |

Copper contamination Exposure to fluorescent light Exposure to sunlight |

Avoid usage of copper utensils Protect product from direct exposure to Sunlight/ UV light |

|

3 |

Yeast/cheesy |

Contaminating yeast growth |

Sanitation check |

|

4 |

Rancid flavor |

Lipolytic activity |

Do not mix pasteurized and raw dairy ingredients prior to homogenization |

|

5 |

High acid |

Addition of more culture, Increased incubation time Use of sour milk |

Optimum culture addition Blast cool the product immediately after optimum pH is reached Use good quality fresh milk

|

|

Body and textural defects |

|||

|

1 |

Weak body |

Insufficient heat treatment to the mix Too low milk SNF Severe agitation after fermentation |

Heat treatment should not be less than 85oC/30min Homogenize the dahi mix prior to homogenization Increase the MSNF content to 11% by adding Skim milk powder |

|

2 |

Grainy texture |

High acidity Improper dispersion of Skim milk powder |

Rapidly cool the product to <5oC after attaining optimum acidity Use in line screen/filter |

|

3

|

Syneresis

|

Insufficient heat treatment to the mix Improper standardization and too low milk SNF Agitation/disturbances during fermentation

|

Heat treatment should not be less than 85oC/30min Increase the MSNF content to min. of 11% by adding Skim milk powder Do not disturb the cups during fermentation |

|

4 |

Ropiness |

Contamination of milk with psychotropic microorganisms

Culture contamination/impure culture |

Proper heat treatment of milk, Avoid cold storage of milk before pasteurization/thermization

Use of pure culture |

References

Kanawjia, S.K., 2006. Developments in the manufacture of lassi. In: Developments in Traditional Dairy Products, lecture compendium of the 21st short course. CAS in Dairy Technology, NDRI, Karnal. Pp: 55-63

Aneja, R.P., Mathur, B.N., Chandan, R.C. and Banerjee, A.K. 2002. Technology of Indian Milk Products. A dairy India Publication, Delhi, India